Embossing creates a raised design on materials such as paper, leather, or metal by pressing from the back, enhancing texture and visual appeal. Debossing, conversely, involves pressing the design into the surface to create an indented effect, offering a subtle yet sophisticated look. Both techniques add tactile dimension and can be chosen based on the desired aesthetic impact and application.

Table of Comparison

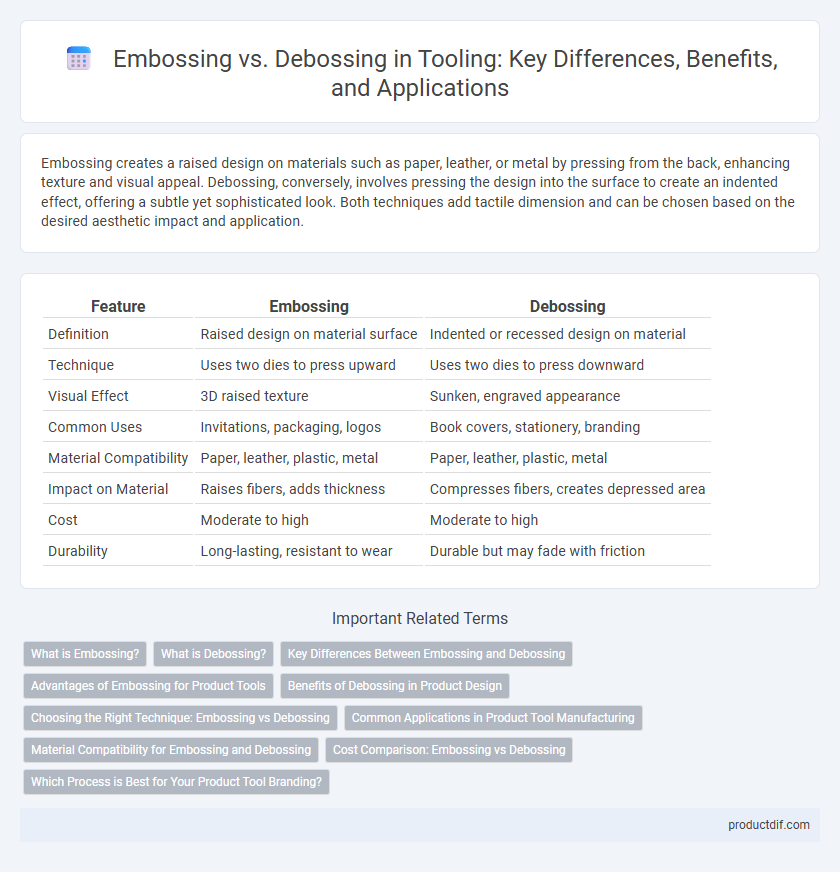

| Feature | Embossing | Debossing |

|---|---|---|

| Definition | Raised design on material surface | Indented or recessed design on material |

| Technique | Uses two dies to press upward | Uses two dies to press downward |

| Visual Effect | 3D raised texture | Sunken, engraved appearance |

| Common Uses | Invitations, packaging, logos | Book covers, stationery, branding |

| Material Compatibility | Paper, leather, plastic, metal | Paper, leather, plastic, metal |

| Impact on Material | Raises fibers, adds thickness | Compresses fibers, creates depressed area |

| Cost | Moderate to high | Moderate to high |

| Durability | Long-lasting, resistant to wear | Durable but may fade with friction |

What is Embossing?

Embossing is a printing technique that creates a raised, three-dimensional design on materials like paper, leather, or metal by pressing a shaped die into the surface. This process adds texture and depth, enhancing the visual appeal and tactile experience of products such as business cards, book covers, and packaging. Embossing often highlights logos, text, or intricate patterns, making them stand out prominently without using ink or foil.

What is Debossing?

Debossing is a technique where a design or text is pressed into a material, creating an indented or recessed impression on the surface. This method enhances the tactile and visual appeal of paper, leather, or metal products by producing a subtle, elegant effect. Commonly used in branding and packaging, debossing adds texture and depth without using additional colors or inks.

Key Differences Between Embossing and Debossing

Embossing raises the design above the surface of the material, creating a three-dimensional effect, while debossing presses the design into the surface, producing an indented impression. Embossing enhances visibility and tactile appeal, often used for logos and intricate patterns, whereas debossing offers a subtle, elegant texture suitable for branding and decorative purposes. Both techniques require specialized dies and presses but differ significantly in visual impact and application.

Advantages of Embossing for Product Tools

Embossing enhances product tools by adding a raised, tactile texture that improves grip and user control, reducing slippage during use. This method increases visual appeal and brand recognition by creating a distinctive, professional finish that stands out on packaging and labels. The durability of embossed surfaces resists wear and tear, extending the lifespan of the tool's markings and logos.

Benefits of Debossing in Product Design

Debossing enhances product design by creating subtle, tactile impressions that improve brand recognition and user engagement through distinctive visual appeal and texture. It offers durability and longevity, ensuring logos and text maintain clarity even with frequent handling. This technique also adds a premium feel to packaging or materials, elevating perceived value and customer experience.

Choosing the Right Technique: Embossing vs Debossing

Embossing raises the design above the surface, creating a textured, eye-catching effect, while debossing presses the image into the material for a subtle, recessed look. Selecting the right technique depends on the desired visual impact, material type, and project purpose, with embossing ideal for bold emphasis and debossing suited for understated elegance. Consider factors like ink layering, lighting, and tactile sensation to enhance branding or product presentation effectively.

Common Applications in Product Tool Manufacturing

Embossing and debossing are widely utilized in product tool manufacturing to enhance visual appeal and tactile experience on materials such as metal, plastic, and leather. Embossing raises a design above the surface, often applied in branding tools, nameplates, and packaging molds to create prominent logos or patterns. Debossing, which indents the design into the material, is commonly used for serial numbers, control panels, and instrument controls to provide durable, recessed markings resistant to wear.

Material Compatibility for Embossing and Debossing

Embossing and debossing techniques require specific material compatibility to achieve the best results; embossing works optimally with thicker, more pliable materials such as leather, cardstock, and certain plastics that can withstand pressure without tearing. Debossing is ideal for softer materials like paper, leather, and fabric where the design is pressed inward, creating a recessed effect without compromising the material's integrity. Selecting the right material ensures durability and clarity in both embossing and debossing applications, enhancing the overall aesthetic and tactile quality.

Cost Comparison: Embossing vs Debossing

Embossing typically incurs higher costs than debossing due to the creation of raised designs requiring thicker plates and more complex dies. Debossing, which involves pressing the design into the material, often uses simpler tooling and less material manipulation, resulting in lower production expenses. Factors like setup time, material type, and production volume also influence the overall cost difference between embossing and debossing techniques.

Which Process is Best for Your Product Tool Branding?

Embossing raises the design above the surface of your product tool, creating a tactile, three-dimensional effect that enhances visual appeal and brand recognition. Debossing presses the design into the surface, offering a subtle, recessed finish ideal for sleek, minimalist branding on metal, plastic, or leather tools. Choose embossing for bold, eye-catching logos that stand out, and debossing for refined, elegant branding that integrates seamlessly with the tool's material texture.

Embossing vs Debossing Infographic

productdif.com

productdif.com