Heat guns and soldering irons serve distinct purposes in electronics and tool projects; heat guns distribute hot air over a broad area, ideal for heat shrinking and paint removal, while soldering irons provide precise, direct heat essential for melting solder on electronic components. A heat gun's adjustable temperature settings and airflow control make it versatile for applications requiring controlled heat without contact, whereas soldering irons excel in tasks demanding accuracy and fine-tip manipulation. Choosing between the two depends on the project's requirements, prioritizing either broad heat for surface tasks or pinpoint heat for detailed soldering work.

Table of Comparison

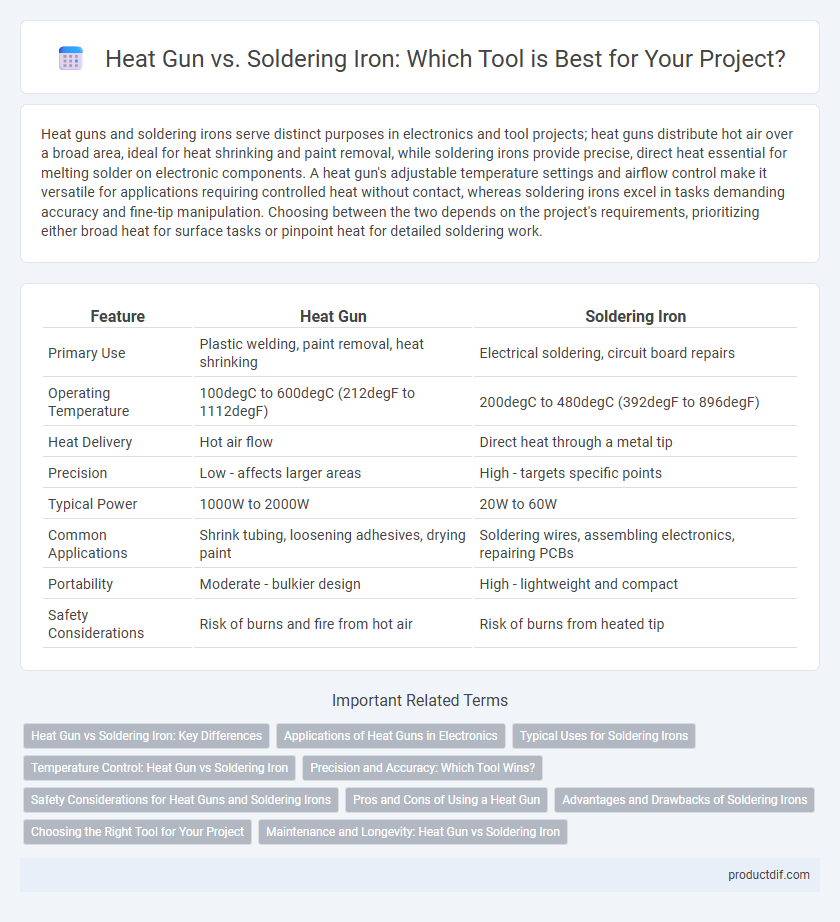

| Feature | Heat Gun | Soldering Iron |

|---|---|---|

| Primary Use | Plastic welding, paint removal, heat shrinking | Electrical soldering, circuit board repairs |

| Operating Temperature | 100degC to 600degC (212degF to 1112degF) | 200degC to 480degC (392degF to 896degF) |

| Heat Delivery | Hot air flow | Direct heat through a metal tip |

| Precision | Low - affects larger areas | High - targets specific points |

| Typical Power | 1000W to 2000W | 20W to 60W |

| Common Applications | Shrink tubing, loosening adhesives, drying paint | Soldering wires, assembling electronics, repairing PCBs |

| Portability | Moderate - bulkier design | High - lightweight and compact |

| Safety Considerations | Risk of burns and fire from hot air | Risk of burns from heated tip |

Heat Gun vs Soldering Iron: Key Differences

Heat guns and soldering irons serve distinct functions in electronics and crafting, with heat guns providing broad, adjustable heat for tasks like shrink tubing and paint stripping, while soldering irons deliver precise, concentrated heat essential for melting solder. Heat guns operate at higher temperatures, typically ranging from 100degC to 600degC, suitable for surface heating, whereas soldering irons usually maintain a stable temperature around 200degC to 450degC for delicate electronic connections. The choice between these tools depends on the application's precision requirements and heat distribution needs, emphasizing heat guns for generalized heating and soldering irons for detailed, component-level work.

Applications of Heat Guns in Electronics

Heat guns are essential in electronics for tasks such as desoldering components, heat-shrinking tubing, and reflowing surface-mount solder joints. Their adjustable temperature settings and focused airflow allow precise control to prevent damage to sensitive circuit boards. Unlike soldering irons, heat guns enable uniform heating over larger areas, making them ideal for repairing and modifying electronic assemblies.

Typical Uses for Soldering Irons

Soldering irons are primarily used for electronics assembly, repair, and precision metal joining tasks, making them ideal for circuit board work and small electrical connections. Their fine tips allow controlled heat application to melt solder without damaging surrounding components. This precision contrasts with heat guns, which are better suited for broader heating tasks like shrink tubing or paint removal.

Temperature Control: Heat Gun vs Soldering Iron

Heat guns provide adjustable temperature settings typically ranging from 100degC to 600degC, making them ideal for tasks requiring broad heat distribution such as shrink tubing and paint removal. Soldering irons offer precise temperature control usually between 200degC and 480degC, essential for delicate electronic soldering and preventing component damage. The precision of soldering irons ensures targeted heating, while heat guns deliver versatile heat application for larger surface areas.

Precision and Accuracy: Which Tool Wins?

Heat guns offer broad, even heat distribution ideal for shrinking tubing or paint stripping but lack the precision required for delicate electronics work. Soldering irons deliver targeted heat with controlled tips, enabling high accuracy in joining small components on circuit boards. For tasks demanding fine precision and accuracy, soldering irons are the superior choice over heat guns.

Safety Considerations for Heat Guns and Soldering Irons

Heat guns operate at much higher temperatures and emit strong blasts of hot air, increasing the risk of burns and fire hazards compared to soldering irons, which have more precise, localized heat. Proper ventilation is essential for heat guns due to the potential release of toxic fumes from melted materials, while soldering irons require careful handling of molten solder and flux fumes to prevent respiratory irritation. Always use heat-resistant gloves, eye protection, and work in well-ventilated areas to minimize risks associated with both tools.

Pros and Cons of Using a Heat Gun

Heat guns provide versatile heat application suitable for shrink wrapping, paint stripping, and loosening adhesive, offering a broad temperature range and airflow control not available in soldering irons. However, heat guns lack the precision required for delicate electronic soldering tasks and can risk damaging sensitive components due to their high, diffuse heat output. Their larger size and slower heat-up time make them less ideal for fine, detailed work compared to the focused, instant heat delivery of soldering irons.

Advantages and Drawbacks of Soldering Irons

Soldering irons offer precise temperature control and are ideal for small-scale electronics repair and delicate soldering tasks, providing clean and reliable joints. However, their limited heat output and slower warm-up time can be a drawback for larger projects or continuous heavy-duty use. They also require careful handling to avoid damage to sensitive components due to direct contact with the heated tip.

Choosing the Right Tool for Your Project

Selecting the right tool depends on the project's requirements, with a heat gun ideal for tasks like shrink tubing, paint stripping, and plastic welding due to its broad heat distribution. A soldering iron excels in precision work such as joining electronic components, making it indispensable for circuit board repairs and fine metalwork. Understanding the temperature control, tip design, and application scope ensures efficient results and prevents damage to sensitive materials.

Maintenance and Longevity: Heat Gun vs Soldering Iron

Heat guns require regular cleaning of the nozzle and fan to prevent overheating and maintain airflow, while soldering irons need frequent tip cleaning and occasional tip replacement to ensure consistent heat transfer. Proper storage and avoiding prolonged idle heating extend the lifespan of both tools, with soldering irons generally lasting longer due to their simpler internal components. Choosing quality brands and using appropriate accessories significantly enhances the maintenance ease and overall durability of heat guns and soldering irons.

Heat gun vs Soldering iron Infographic

productdif.com

productdif.com