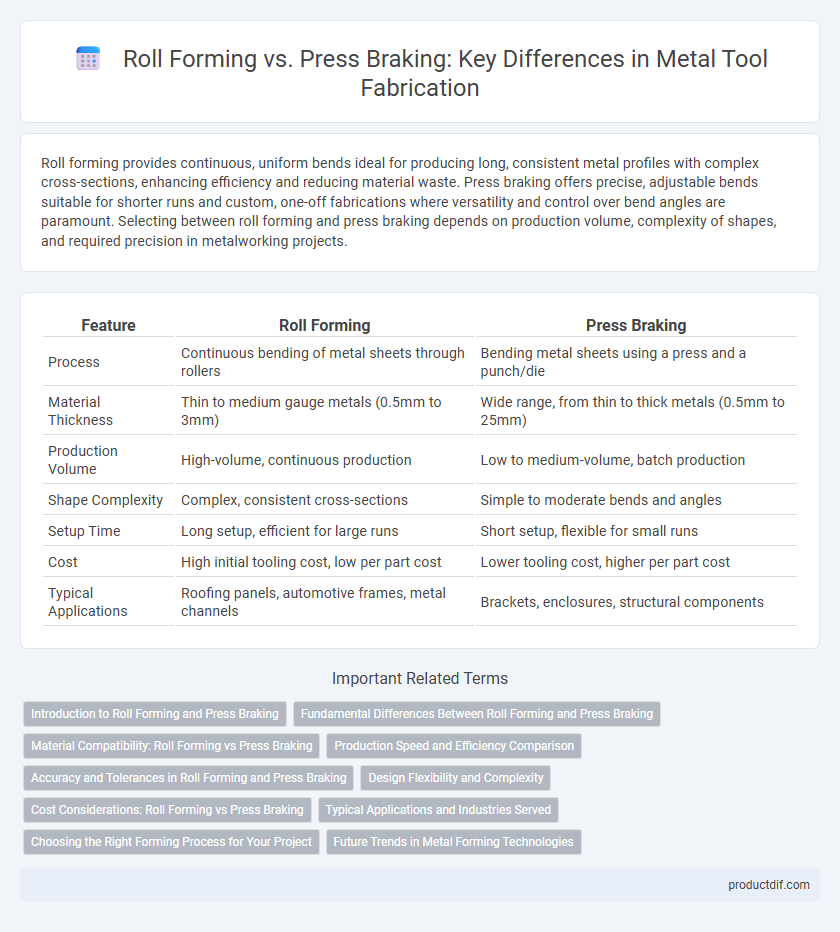

Roll forming provides continuous, uniform bends ideal for producing long, consistent metal profiles with complex cross-sections, enhancing efficiency and reducing material waste. Press braking offers precise, adjustable bends suitable for shorter runs and custom, one-off fabrications where versatility and control over bend angles are paramount. Selecting between roll forming and press braking depends on production volume, complexity of shapes, and required precision in metalworking projects.

Table of Comparison

| Feature | Roll Forming | Press Braking |

|---|---|---|

| Process | Continuous bending of metal sheets through rollers | Bending metal sheets using a press and a punch/die |

| Material Thickness | Thin to medium gauge metals (0.5mm to 3mm) | Wide range, from thin to thick metals (0.5mm to 25mm) |

| Production Volume | High-volume, continuous production | Low to medium-volume, batch production |

| Shape Complexity | Complex, consistent cross-sections | Simple to moderate bends and angles |

| Setup Time | Long setup, efficient for large runs | Short setup, flexible for small runs |

| Cost | High initial tooling cost, low per part cost | Lower tooling cost, higher per part cost |

| Typical Applications | Roofing panels, automotive frames, metal channels | Brackets, enclosures, structural components |

Introduction to Roll Forming and Press Braking

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel, passes through consecutive sets of rolls to achieve a desired cross-sectional profile. Press braking involves bending sheet metal by pressing it between a punch and die using a press brake machine, enabling precise angle and shape control. Both methods are essential in metal fabrication, with roll forming excelling in high-volume production and press braking offering versatility for custom or shorter runs.

Fundamental Differences Between Roll Forming and Press Braking

Roll forming involves continuous bending of long metal strips through successive roller dies, enabling high-volume production of uniform cross-sections with minimal material waste. Press braking uses a punch and die to bend sheet metal at specific angles, offering flexibility for varied shapes but with slower processing speeds and higher labor input. The fundamental difference lies in roll forming's continuous, automated shaping versus press braking's batch-wise, manual bending process.

Material Compatibility: Roll Forming vs Press Braking

Roll forming excels with continuous, thin-gauge metals like aluminum and steel, maintaining uniform thickness and minimizing material stress. Press braking offers versatile compatibility across thicker metals and varied alloys, accommodating sharper bends but may introduce localized deformation and spring-back. Choosing between roll forming and press braking hinges on the metal's thickness, ductility, and final shape precision requirements.

Production Speed and Efficiency Comparison

Roll forming offers higher production speed compared to press braking by continuously shaping metal coils through a series of rollers, enabling rapid and consistent output for long runs. Press braking provides greater flexibility for short production runs or custom bends but operates at slower cycle times due to its step-by-step bending process. Efficiency in roll forming is superior for high-volume manufacturing, minimizing material waste and labor costs, while press braking is advantageous for low-volume, precision tasks requiring frequent setup changes.

Accuracy and Tolerances in Roll Forming and Press Braking

Roll forming offers superior accuracy and tighter tolerances compared to press braking due to its continuous bending process, which minimizes material deformation and spring-back effects. Press braking can achieve precise bends but often requires multiple adjustments and may exhibit variability in angle accuracy, especially on thicker materials. The consistent feed and gradual deformation in roll forming enable high repeatability and uniformity ideal for mass production with stringent tolerance requirements.

Design Flexibility and Complexity

Roll forming offers superior design flexibility for continuous profiles with consistent cross-sections, enabling complex shapes that are difficult to achieve with press braking. Press braking excels in producing varied bends and intricate geometries on shorter runs, making it ideal for prototypes and low-volume production. The choice between roll forming and press braking depends on the complexity of the design, production volume, and required precision.

Cost Considerations: Roll Forming vs Press Braking

Roll forming offers lower per-part costs for high-volume production due to continuous processing and minimal material waste, making it cost-efficient for long runs. Press braking typically incurs higher labor and setup costs but remains economical for low-volume or custom jobs requiring flexibility. Initial tooling expenses are higher for roll forming, whereas press braking requires less upfront investment, influencing overall cost decisions based on production scale.

Typical Applications and Industries Served

Roll forming is widely used in manufacturing long, uniform metal profiles for construction, automotive, and appliance industries, particularly for producing roofing panels, door frames, and automotive body parts. Press braking excels in custom or short-run fabrication, commonly serving industries such as aerospace, shipbuilding, and metal fabrication shops for creating precise bends in sheet metal components. Both methods address specific production needs, with roll forming suited for high-volume, continuous production and press braking optimal for versatility in complex, smaller batch metal forming tasks.

Choosing the Right Forming Process for Your Project

Roll forming offers continuous bending of long metal sheets, ideal for high-volume production with consistent cross-sections; press braking provides flexibility for custom, small-batch runs with precise angle control on individual parts. Selecting the right forming process depends on project volume, material thickness, and complexity of design, where roll forming suits repetitive profiles and press braking excels in versatility and shorter setup times. Understanding these factors ensures optimal tool investment, reduced lead times, and improved overall manufacturing efficiency.

Future Trends in Metal Forming Technologies

Roll forming advancements emphasize automation and precision, integrating AI-driven controls for consistent high-volume production. Press braking evolves through adaptive systems using real-time sensor feedback to minimize material waste and enhance component complexity. Emerging hybrid techniques combine roll forming efficiency with press braking flexibility, shaping the future of sustainable and cost-effective metal forming solutions.

Roll Forming vs Press Braking Infographic

productdif.com

productdif.com