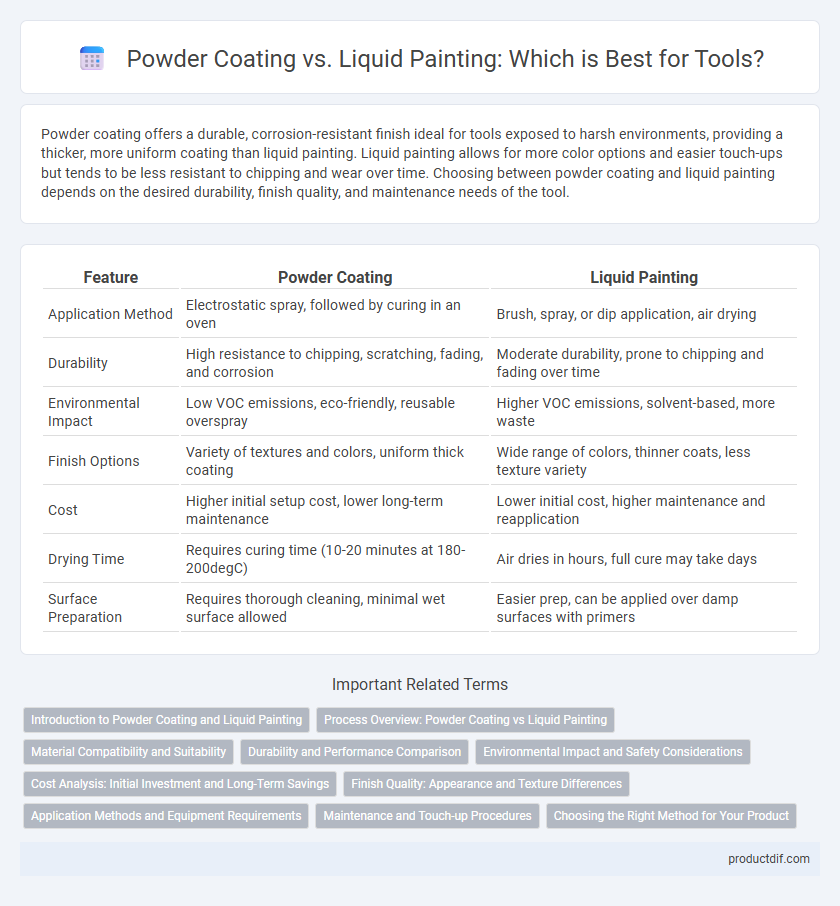

Powder coating offers a durable, corrosion-resistant finish ideal for tools exposed to harsh environments, providing a thicker, more uniform coating than liquid painting. Liquid painting allows for more color options and easier touch-ups but tends to be less resistant to chipping and wear over time. Choosing between powder coating and liquid painting depends on the desired durability, finish quality, and maintenance needs of the tool.

Table of Comparison

| Feature | Powder Coating | Liquid Painting |

|---|---|---|

| Application Method | Electrostatic spray, followed by curing in an oven | Brush, spray, or dip application, air drying |

| Durability | High resistance to chipping, scratching, fading, and corrosion | Moderate durability, prone to chipping and fading over time |

| Environmental Impact | Low VOC emissions, eco-friendly, reusable overspray | Higher VOC emissions, solvent-based, more waste |

| Finish Options | Variety of textures and colors, uniform thick coating | Wide range of colors, thinner coats, less texture variety |

| Cost | Higher initial setup cost, lower long-term maintenance | Lower initial cost, higher maintenance and reapplication |

| Drying Time | Requires curing time (10-20 minutes at 180-200degC) | Air dries in hours, full cure may take days |

| Surface Preparation | Requires thorough cleaning, minimal wet surface allowed | Easier prep, can be applied over damp surfaces with primers |

Introduction to Powder Coating and Liquid Painting

Powder coating involves applying a dry powder electrostatically to metal surfaces, then curing it under heat to form a durable, protective finish resistant to chipping and corrosion. Liquid painting uses solvent-based or water-based paints applied with brushes, rollers, or spray equipment, offering a smooth, customizable surface but often requiring multiple coats and longer drying times. Both techniques serve industrial and decorative purposes, with powder coating favored for its environmental benefits and longevity, while liquid painting provides versatility in color and texture.

Process Overview: Powder Coating vs Liquid Painting

Powder coating involves applying dry, electrostatically charged powder onto a metal surface, which is then cured under heat to form a durable finish, while liquid painting uses a liquid solvent-based or water-based paint applied by spray, brush, or roller that dries through evaporation. Powder coating typically offers a thicker, more uniform coating with better resistance to chipping, corrosion, and fading compared to liquid painting. Liquid painting allows for a wider variety of colors and finishes but generally requires longer drying times and more environmental controls due to volatile organic compounds (VOCs).

Material Compatibility and Suitability

Powder coating offers superior adhesion and durability on metals such as steel and aluminum, making it ideal for automotive and industrial tools. Liquid painting provides better compatibility with a broader range of materials, including plastics and wood, due to its flexible application and curing process. Selecting between powder coating and liquid painting depends on the substrate type and desired finish quality, with powder coating excelling in corrosion resistance and liquid paint offering versatile color options.

Durability and Performance Comparison

Powder coating offers superior durability compared to liquid painting due to its thicker, more uniform finish that resists chipping, scratching, and fading under harsh environmental conditions. Its performance excels in corrosion resistance and impact strength, making it ideal for outdoor and industrial applications. Liquid painting, while versatile and easier to touch up, typically requires more frequent maintenance and recoating to maintain its protective qualities.

Environmental Impact and Safety Considerations

Powder coating produces fewer volatile organic compounds (VOCs) compared to liquid painting, significantly reducing air pollution and hazardous emissions. The overspray from powder coating can be collected and reused, minimizing waste, while liquid paints often contain harmful solvents requiring special disposal. Safety considerations favor powder coating due to lower exposure to toxic chemicals and reduced risk of fire hazards, making it a more environmentally friendly and safer option for industrial applications.

Cost Analysis: Initial Investment and Long-Term Savings

Powder coating typically requires a higher initial investment due to the need for specialized spray equipment and curing ovens, yet it offers long-term savings through reduced material waste and lower energy consumption. Liquid painting involves lower upfront costs with simpler application tools but incurs higher ongoing expenses from solvent use, longer drying times, and frequent reapplications. Over time, powder coating proves more cost-effective by minimizing maintenance and maximizing durability, essential for industrial and automotive tool finishes.

Finish Quality: Appearance and Texture Differences

Powder coating creates a thicker, more durable finish with a smooth, uniform texture that resists chipping and fading, making it ideal for metal tools requiring long-lasting protection. Liquid painting offers a versatile finish with a glossy or matte appearance, but may show brush strokes or uneven texture and is more prone to wear over time. The choice between powder coating and liquid painting depends on the desired finish quality, durability needs, and aesthetic preferences for the tool.

Application Methods and Equipment Requirements

Powder coating requires specialized electrostatic spray equipment to apply dry powder particles evenly, which are then cured under heat to form a durable finish, making it ideal for metal surfaces. Liquid painting utilizes conventional spray guns, brushes, or rollers, providing flexibility for various materials and intricate shapes but often demands longer drying times and ventilation setups. Equipment costs and maintenance differ significantly, with powder coating systems typically involving higher initial investment and energy usage compared to liquid painting tools.

Maintenance and Touch-up Procedures

Powder coating offers superior durability with minimal maintenance, resisting chipping and fading better than liquid paint, which often requires more frequent touch-ups. Touch-up procedures for powder coating typically involve reapplication by professionals using baking equipment to ensure adhesion, whereas liquid paint touch-ups can be done on-site with brushes or spray cans. These differences make powder coating preferable for tools exposed to harsh environments, while liquid paint suits decorative applications needing easier, immediate repairs.

Choosing the Right Method for Your Product

Powder coating offers superior durability and resistance to corrosion, making it ideal for metal tools exposed to harsh conditions, while liquid painting provides greater color variety and smoother finishes for intricate designs. Consider the product's material, intended use, and environmental exposure when selecting between powder coating and liquid painting to ensure optimal protection and aesthetics. Cost efficiency also varies, with powder coating generally being more eco-friendly and long-lasting, often reducing maintenance expenses over time.

Powder Coating vs Liquid Painting Infographic

productdif.com

productdif.com