Single-use tools are designed for one-time applications, ensuring precision and reducing contamination risks, especially in medical or specialized industrial settings. Multi-use tools offer durability and cost-effectiveness, providing versatility across various tasks while requiring proper maintenance to sustain performance. Choosing between single-use and multi-use tools depends on factors like frequency of use, hygiene standards, and budget constraints.

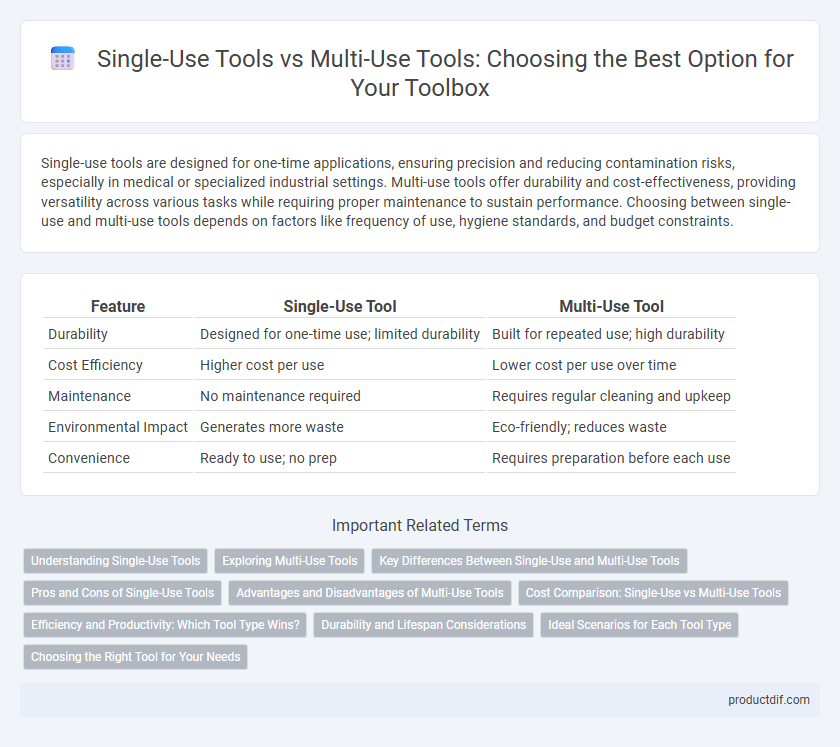

Table of Comparison

| Feature | Single-Use Tool | Multi-Use Tool |

|---|---|---|

| Durability | Designed for one-time use; limited durability | Built for repeated use; high durability |

| Cost Efficiency | Higher cost per use | Lower cost per use over time |

| Maintenance | No maintenance required | Requires regular cleaning and upkeep |

| Environmental Impact | Generates more waste | Eco-friendly; reduces waste |

| Convenience | Ready to use; no prep | Requires preparation before each use |

Understanding Single-Use Tools

Single-use tools are designed for one-time applications to ensure precision and prevent contamination, commonly used in medical, laboratory, and manufacturing settings. These tools, often crafted from lightweight materials like plastic or stainless steel, offer cost-effectiveness by eliminating the need for sterilization while maintaining high hygiene standards. Understanding single-use tools involves recognizing their role in minimizing cross-contamination risks and improving workflow efficiency in environments requiring strict cleanliness.

Exploring Multi-Use Tools

Multi-use tools offer enhanced versatility and cost-efficiency by combining multiple functions into a single device, reducing the need for separate equipment. These tools improve workflow efficiency in various industries, including construction, automotive repair, and medical applications, by minimizing downtime and tool changes. The durability and adaptability of multi-use tools make them an environmentally sustainable choice compared to disposable, single-use alternatives.

Key Differences Between Single-Use and Multi-Use Tools

Single-use tools are designed for one-time application, offering maximum sterilization and minimizing cross-contamination risks, making them ideal for medical and precision tasks. Multi-use tools, crafted from durable materials like stainless steel or high-grade plastics, provide cost efficiency and environmental benefits through repeated sterilization and reuse. The choice between single-use and multi-use tools depends on factors such as required precision, hygiene standards, cost constraints, and environmental impact considerations.

Pros and Cons of Single-Use Tools

Single-use tools offer advantages such as superior hygiene, reduced risk of cross-contamination, and consistent performance in precision tasks, making them ideal for medical and laboratory applications. However, they generate more waste, have higher recurring costs, and may lack the durability and strength found in multi-use tools. Choosing single-use tools depends on prioritizing safety and convenience over long-term cost efficiency and environmental impact.

Advantages and Disadvantages of Multi-Use Tools

Multi-use tools offer significant cost-efficiency by reducing the need for frequent replacements, making them ideal for long-term projects and varied applications. Their durability and versatility enhance productivity, but require regular maintenance to prevent wear and potential malfunction. However, the initial investment and time spent on cleaning and upkeep can be a disadvantage compared to single-use tools designed for one-time tasks.

Cost Comparison: Single-Use vs Multi-Use Tools

Single-use tools generally have a lower upfront cost but incur higher expenses over time due to frequent replacement, making them less cost-effective for long-term projects. Multi-use tools require an initial investment but offer greater durability and reduced costs per use, providing better value in continuous or repetitive applications. The choice between single-use and multi-use tools significantly impacts overall budget allocation based on project duration and frequency of tool usage.

Efficiency and Productivity: Which Tool Type Wins?

Single-use tools offer high efficiency for specific tasks by eliminating the need for setup or maintenance, reducing downtime and allowing workers to focus solely on the job at hand. Multi-use tools provide greater overall productivity through versatility and cost-effectiveness, enabling seamless transitions between different applications without constantly replacing equipment. Choosing between single-use and multi-use tools depends on balancing immediate task efficiency with long-term workflow productivity and resource management.

Durability and Lifespan Considerations

Single-use tools are designed for one-time applications, offering limited durability and a much shorter lifespan compared to multi-use tools. Multi-use tools are constructed from robust materials like high-grade steel or reinforced composites, enabling extended durability and repeated usage over time. Choosing between single-use and multi-use tools depends on performance requirements, cost-effectiveness, and the expected frequency of use in various industrial or professional settings.

Ideal Scenarios for Each Tool Type

Single-use tools are ideal for tasks requiring absolute hygiene, contamination prevention, or precision where tool wear could affect results, such as medical procedures and laboratory testing. Multi-use tools excel in environments where durability, cost-efficiency, and versatility are prioritized, including general maintenance, construction, and crafting projects. Choosing between single-use and multi-use tools depends on factors like frequency of use, sterility requirements, and overall budget constraints.

Choosing the Right Tool for Your Needs

Selecting the right tool depends on task frequency, budget, and hygiene requirements. Single-use tools offer sterilization benefits and reduce contamination risks, ideal for medical or precise applications. Multi-use tools provide durability and cost efficiency for repetitive tasks, requiring proper maintenance to ensure longevity.

Single-Use Tool vs Multi-Use Tool Infographic

productdif.com

productdif.com