A Palm Sander offers precision and ease of use for fine finishing and detail work on smaller surfaces, making it ideal for woodworking and furniture refinishing. In contrast, a Belt Sander delivers powerful abrasive action suited for quickly removing material on large, flat surfaces, perfect for heavy-duty tasks like leveling rough lumber or stripping paint. Choosing between the two depends on the project's scale and required finish quality, with palm sanders excelling in control and belt sanders in aggressive sanding.

Table of Comparison

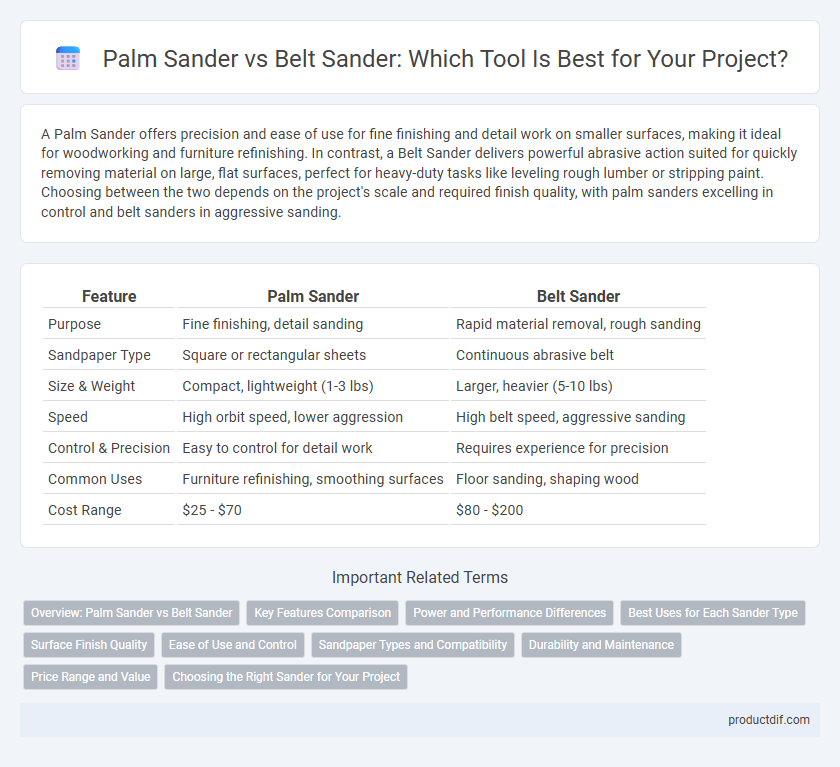

| Feature | Palm Sander | Belt Sander |

|---|---|---|

| Purpose | Fine finishing, detail sanding | Rapid material removal, rough sanding |

| Sandpaper Type | Square or rectangular sheets | Continuous abrasive belt |

| Size & Weight | Compact, lightweight (1-3 lbs) | Larger, heavier (5-10 lbs) |

| Speed | High orbit speed, lower aggression | High belt speed, aggressive sanding |

| Control & Precision | Easy to control for detail work | Requires experience for precision |

| Common Uses | Furniture refinishing, smoothing surfaces | Floor sanding, shaping wood |

| Cost Range | $25 - $70 | $80 - $200 |

Overview: Palm Sander vs Belt Sander

Palm sanders offer precision and ease for fine sanding with a compact, lightweight design ideal for small surfaces and detailed work. Belt sanders deliver powerful, aggressive material removal suited for large, flat areas and heavy-duty sanding tasks. Choosing between them depends on the sanding project's scale, surface type, and desired finish quality.

Key Features Comparison

Palm sanders offer precision with a compact design and finer grit sanding, ideal for detail work and smooth finishes on smaller surfaces. Belt sanders provide powerful, continuous sanding with a moving abrasive belt, suitable for quickly removing material from large, flat surfaces and heavy-duty tasks. Key features include palm sanders' lightweight build and orbital motion versus belt sanders' high-speed belt movement and greater material removal rate.

Power and Performance Differences

Palm sanders typically deliver lower power output, around 1 to 2 amps, making them ideal for fine finishing and smooth sanding on wood surfaces. Belt sanders feature more powerful motors, often exceeding 5 amps, designed for aggressive material removal and rapid stock stripping on larger projects. The higher motor power in belt sanders results in greater sanding efficiency and faster performance, while palm sanders prioritize control and precision in delicate tasks.

Best Uses for Each Sander Type

Palm sanders excel in detailed finishing tasks such as smoothing wood surfaces, removing light paint, and preparing smaller projects due to their compact size and ease of control. Belt sanders are ideal for heavy-duty applications like rapidly removing large amounts of material, leveling rough surfaces, and sanding hardwood floors thanks to their powerful motor and continuous abrasive belt. Choosing the right sander depends on the project scale and surface type, with palm sanders suited for precision work and belt sanders designed for efficiency in large, tough sanding jobs.

Surface Finish Quality

Palm sanders provide a finer surface finish by utilizing rapid orbital motions that minimize swirl marks, making them ideal for delicate woodwork and smooth finishing. Belt sanders remove material quickly with a continuous abrasive belt but often leave deeper scratches and a rougher texture, requiring additional sanding for a polished surface. Choosing between a palm sander and a belt sander depends on the desired finish quality and the specific sanding task.

Ease of Use and Control

Palm sanders offer superior ease of use and control due to their lightweight design and ergonomic grip, allowing precise sanding on small or delicate surfaces. Belt sanders, while powerful and efficient for large-scale material removal, can be more challenging to maneuver and require steady handling to avoid gouging. Choosing between the two depends on the project size and the need for fine detail versus rapid stock removal.

Sandpaper Types and Compatibility

Palm sanders typically use circular or rectangular hook-and-loop sandpaper pads ranging from 80 to 320 grit, offering compatibility with fine to medium sanding tasks. Belt sanders require continuous loop sandpaper belts that come in grits from 40 to 120, designed for heavy material removal and rough sanding. Choosing the correct sandpaper type and grit for each sander ensures optimal performance and surface finish quality.

Durability and Maintenance

Palm sanders typically feature compact, lightweight designs with durable plastic or metal housings that resist wear and are easy to maintain with simple pad replacements. Belt sanders, constructed with robust metal frames and heavy-duty motors, offer higher durability for intensive sanding tasks but require regular belt changes and occasional motor maintenance to ensure longevity. Choosing between the two depends on the balance between the tool's durability needs and the maintenance effort acceptable for the specific sanding application.

Price Range and Value

Palm sanders typically range from $30 to $100, offering affordability for light to medium sanding tasks with good maneuverability. Belt sanders usually cost between $100 and $200, providing higher power and speed ideal for heavy-duty material removal and large surfaces. Investing in a belt sander delivers greater value for extensive projects, while palm sanders provide cost-effective precision for detailed finishing.

Choosing the Right Sander for Your Project

Palm sanders offer precision and control, ideal for detailed finishing and smaller surfaces, while belt sanders provide powerful material removal suited for large, flat areas and heavy-duty sanding tasks. Consider the project size and desired surface outcome: palm sanders excel in smoothing and fine sanding, whereas belt sanders efficiently handle rough shaping and stripping paint or varnish. Selecting the appropriate sander maximizes efficiency and quality, minimizing effort and preventing damage to the workpiece.

Palm Sander vs Belt Sander Infographic

productdif.com

productdif.com