Rotary tools offer high-speed, precise cutting, grinding, and carving capabilities, making them ideal for detailed work on wood, plastic, and metal. Oscillating tools provide versatile, controlled oscillating motion perfect for sanding, scraping, and cutting in tight spaces or flush with surfaces. Choosing between rotary and oscillating tools depends on the project's requirements for precision, material type, and accessibility.

Table of Comparison

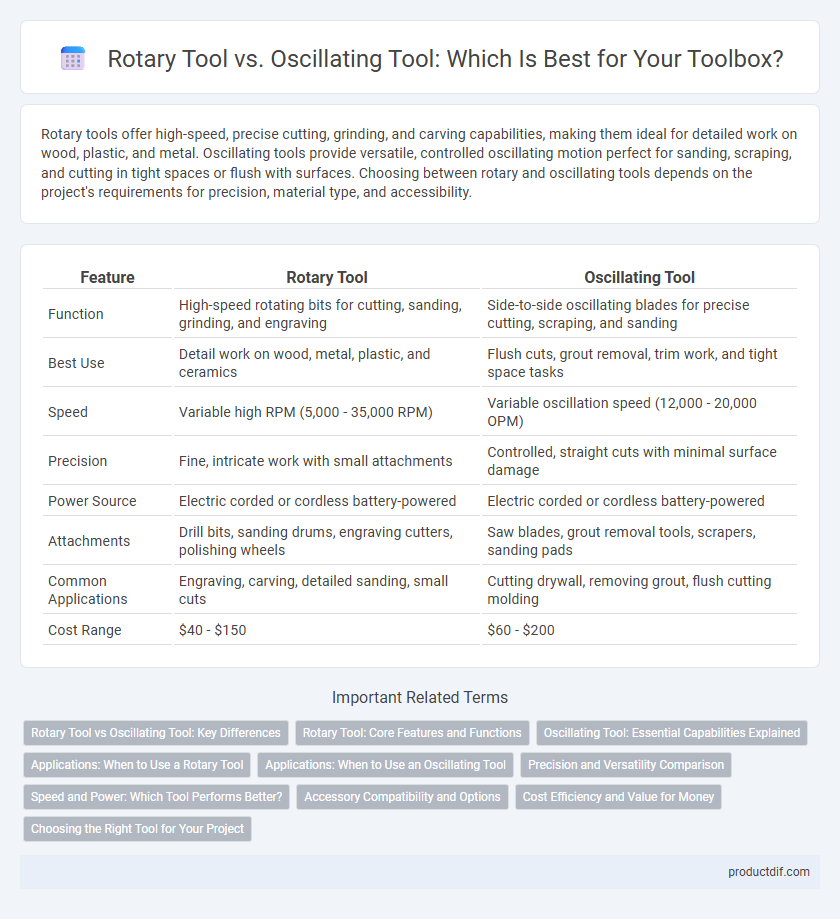

| Feature | Rotary Tool | Oscillating Tool |

|---|---|---|

| Function | High-speed rotating bits for cutting, sanding, grinding, and engraving | Side-to-side oscillating blades for precise cutting, scraping, and sanding |

| Best Use | Detail work on wood, metal, plastic, and ceramics | Flush cuts, grout removal, trim work, and tight space tasks |

| Speed | Variable high RPM (5,000 - 35,000 RPM) | Variable oscillation speed (12,000 - 20,000 OPM) |

| Precision | Fine, intricate work with small attachments | Controlled, straight cuts with minimal surface damage |

| Power Source | Electric corded or cordless battery-powered | Electric corded or cordless battery-powered |

| Attachments | Drill bits, sanding drums, engraving cutters, polishing wheels | Saw blades, grout removal tools, scrapers, sanding pads |

| Common Applications | Engraving, carving, detailed sanding, small cuts | Cutting drywall, removing grout, flush cutting molding |

| Cost Range | $40 - $150 | $60 - $200 |

Rotary Tool vs Oscillating Tool: Key Differences

Rotary tools operate with a high-speed rotating bit ideal for detailed carving, grinding, and cutting tasks, offering precision and versatility on various materials. Oscillating tools use a side-to-side oscillation motion that excels in plunge cuts, sanding edges, and removing grout, providing control in tight spaces without overcutting. The primary difference lies in motion type and application, where rotary tools emphasize speed and detail, and oscillating tools focus on controlled, multi-surface versatility.

Rotary Tool: Core Features and Functions

Rotary tools feature high-speed rotating bits that excel in detailed cutting, grinding, sanding, and polishing tasks across various materials like wood, metal, and plastic. Their compact design and variable speed settings provide precise control for intricate work such as engraving, drilling, and carving. Unlike oscillating tools, rotary tools operate with continuous circular motion, making them ideal for tasks requiring fine detailing and smooth finishing.

Oscillating Tool: Essential Capabilities Explained

Oscillating tools excel in precision cutting, sanding, and scraping due to their rapid, side-to-side blade movement, making them ideal for detailed work in tight spaces. Their versatility includes cutting through wood, metal, plastic, and drywall, with accessories designed for specific tasks like grout removal and plunge cuts. Unlike rotary tools that spin continuously, oscillating tools minimize vibration and heat buildup, enhancing control and safety during extended use.

Applications: When to Use a Rotary Tool

Rotary tools excel in detailed tasks such as engraving, polishing, drilling, and sanding small surfaces or intricate materials, making them ideal for precision work in crafts and DIY projects. Their high-speed rotary motion allows for effective shaping, carving, and grinding on wood, metal, plastic, and glass, especially when working in tight or confined spaces. Unlike oscillating tools, rotary tools offer greater versatility for fine, controlled tasks requiring varying attachments and bit types.

Applications: When to Use an Oscillating Tool

Oscillating tools excel in precision cutting, scraping, grinding, and sanding within tight or hard-to-reach spaces, making them ideal for detailed renovation tasks and removal of grout, caulk, or old paint. Unlike rotary tools, oscillating tools offer superior control and minimal vibration, which reduces damage risk to delicate materials such as drywall, wood trim, or tile edges. They are particularly effective for flush cuts and plunge cuts where accuracy and surface protection are critical.

Precision and Versatility Comparison

Rotary tools offer exceptional precision for detailed tasks like engraving, sanding, and carving with small, high-speed attachments that allow for intricate control. Oscillating tools provide superior versatility when handling a wide range of materials and applications, such as cutting, scraping, grinding, and sanding in tight or awkward spaces due to their multi-directional blade movement. Both tools excel in different areas, with rotary tools preferred for fine, delicate work and oscillating tools favored for multi-functional usage and adaptability on varied projects.

Speed and Power: Which Tool Performs Better?

Rotary tools typically operate at higher speeds, ranging from 5,000 to 35,000 RPM, making them ideal for precision tasks and intricate detailing. Oscillating tools deliver lower speeds, usually between 10,000 to 20,000 OPM (oscillations per minute), but provide greater torque for powerful cutting, sanding, and scraping. When comparing speed and power, rotary tools excel in speed-driven applications, while oscillating tools outperform in power-demanding tasks requiring controlled force.

Accessory Compatibility and Options

Rotary tools offer a wide range of accessory compatibility, including cutting bits, sanding drums, polishing wheels, and engraving tips, making them versatile for detailed work and intricate designs. Oscillating tools feature a broad selection of blade attachments, scraper accessories, and sanding pads, optimized for precise cutting, grinding, and scraping tasks in tight spaces. Both tools support universal accessory adapters, but rotary tools typically provide more miniature and specialized options, while oscillating tools excel with robust, multi-functional blade varieties.

Cost Efficiency and Value for Money

Rotary tools typically offer greater cost efficiency for detailed, small-scale projects due to their affordability and versatile attachments, making them ideal for hobbyists and light-duty tasks. Oscillating tools provide superior value for money in renovation and heavy-duty applications by delivering precise, multi-functional performance that reduces the need for multiple tools. Choosing between them depends on project scope and frequency, with rotary tools excelling in budget-friendly precision and oscillating tools in durable, comprehensive utility.

Choosing the Right Tool for Your Project

Rotary tools offer precision and versatility for detailed tasks like engraving, sanding, and cutting small materials, making them ideal for intricate projects. Oscillating tools excel in rapid, multi-directional cutting and scraping, suited for demolition, grout removal, and flush cuts in tight spaces. Assess project requirements such as material type, tool speed, and accessibility to select the tool that maximizes efficiency and accuracy.

Rotary Tool vs Oscillating Tool Infographic

productdif.com

productdif.com