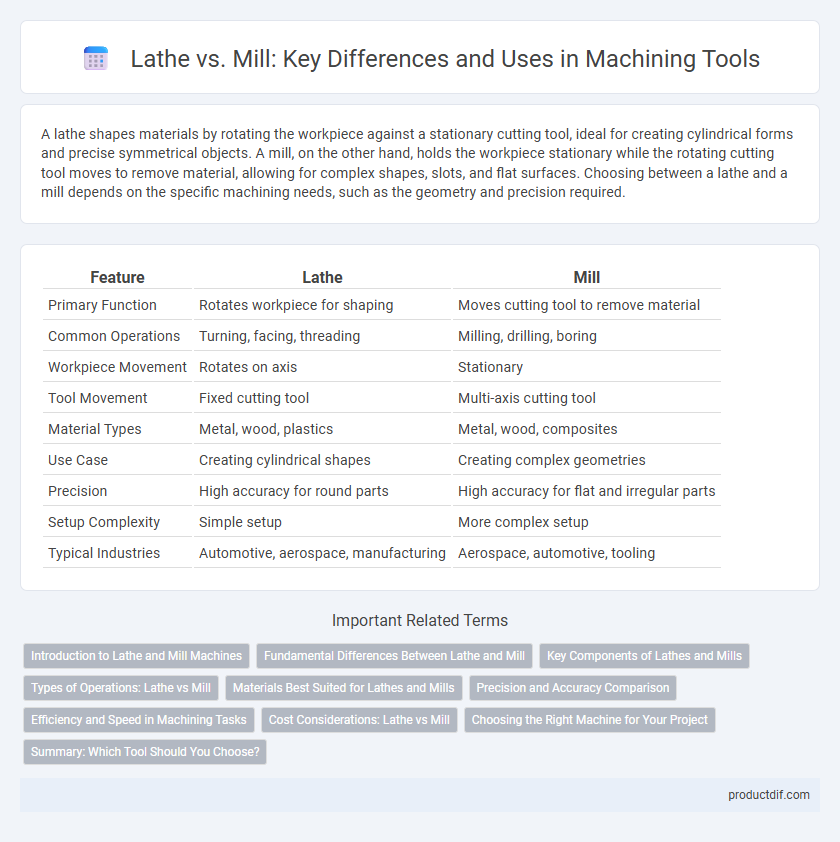

A lathe shapes materials by rotating the workpiece against a stationary cutting tool, ideal for creating cylindrical forms and precise symmetrical objects. A mill, on the other hand, holds the workpiece stationary while the rotating cutting tool moves to remove material, allowing for complex shapes, slots, and flat surfaces. Choosing between a lathe and a mill depends on the specific machining needs, such as the geometry and precision required.

Table of Comparison

| Feature | Lathe | Mill |

|---|---|---|

| Primary Function | Rotates workpiece for shaping | Moves cutting tool to remove material |

| Common Operations | Turning, facing, threading | Milling, drilling, boring |

| Workpiece Movement | Rotates on axis | Stationary |

| Tool Movement | Fixed cutting tool | Multi-axis cutting tool |

| Material Types | Metal, wood, plastics | Metal, wood, composites |

| Use Case | Creating cylindrical shapes | Creating complex geometries |

| Precision | High accuracy for round parts | High accuracy for flat and irregular parts |

| Setup Complexity | Simple setup | More complex setup |

| Typical Industries | Automotive, aerospace, manufacturing | Aerospace, automotive, tooling |

Introduction to Lathe and Mill Machines

Lathe machines specialize in rotating workpieces against cutting tools to perform precise shaping operations such as turning, facing, and threading. Milling machines utilize rotating multi-point cutting tools to remove material from stationary workpieces, enabling complex shapes and slots to be created with high accuracy. Both machines are essential in metalworking and manufacturing, offering complementary capabilities for diverse machining tasks.

Fundamental Differences Between Lathe and Mill

Lathes primarily perform turning operations by rotating the workpiece against a stationary cutting tool, making them ideal for cylindrical shapes. Mills use rotary cutters to remove material from a stationary workpiece, enabling complex shapes and flat surfaces. The fundamental difference lies in the motion: lathes move the workpiece, while mills move the tool.

Key Components of Lathes and Mills

Lathes primarily consist of a headstock with a spindle, a tool post for holding cutting tools, and a tailstock for supporting the workpiece, enabling rotational motion for shaping materials. Mills feature a spindle mounted on a movable table, along with a cutting tool that moves in multiple axes to perform precise material removal. Both machines share critical components like lead screws for movement control and robust frames to ensure stability during machining.

Types of Operations: Lathe vs Mill

Lathes primarily perform turning operations, shaping materials by rotating the workpiece against a cutting tool to produce cylindrical parts such as shafts, bolts, and pulleys. Mills use cutting tools that rotate to remove material from a stationary workpiece, excelling in operations like drilling, slotting, and contouring complex surfaces or flat parts. The fundamental difference lies in the motion; lathes rotate the workpiece while mills rotate the cutting tool to achieve precise machining results.

Materials Best Suited for Lathes and Mills

Lathes are best suited for machining cylindrical materials such as metals, plastics, and wood, offering precision in turning operations. Mills excel in shaping and cutting flat or irregular surfaces on diverse materials including steel, aluminum, and composites. Selecting the appropriate tool depends on the material's shape and the desired machining process for optimal results.

Precision and Accuracy Comparison

Lathes excel in producing precise cylindrical shapes with high rotational accuracy, making them ideal for tasks requiring tight tolerances on symmetrical parts. Mills provide superior precision in creating complex geometries and flat surfaces through multi-axis movements, allowing for greater dimensional accuracy on intricate components. Comparing lathe vs mill, mills generally offer enhanced accuracy for multifaceted designs, while lathes deliver unmatched precision in round part machining.

Efficiency and Speed in Machining Tasks

Lathes excel in high-speed rotational machining tasks, delivering efficient cylindrical shaping and threading with rapid material removal rates. Milling machines provide versatile multi-axis operations, enabling precise and complex surface contours, though generally at slower feed rates compared to lathes. For tasks prioritizing speed and repeatability in turning, lathes offer superior efficiency, whereas milling machines optimize flexibility in machining diverse geometries.

Cost Considerations: Lathe vs Mill

Lathe machines typically have lower upfront costs compared to mills due to their simpler design and fewer components, making them more budget-friendly for basic turning operations. Milling machines require a higher initial investment because of their versatility and precision in handling complex cutting tasks, which can justify the expense for advanced manufacturing needs. Maintenance and tooling expenses also differ, with mills generally incurring higher costs due to more intricate parts and specialized cutting tools.

Choosing the Right Machine for Your Project

Selecting between a lathe and a mill depends on the specific machining requirements of your project, such as the shape and type of material. Lathes excel in producing symmetrical cylindrical parts by rotating the workpiece, while mills are ideal for shaping flat or complex surfaces using a stationary cutting tool. Evaluating factors like precision, complexity, and production volume ensures optimal machine selection for efficiency and accuracy.

Summary: Which Tool Should You Choose?

Choosing between a lathe and a mill depends on the specific machining task: lathes excel at rotating workpieces for shaping cylindrical parts, while mills are ideal for precise cutting and shaping of flat or irregular surfaces. Consider the material type, desired geometry, and production volume when selecting the tool to maximize efficiency and accuracy in manufacturing. Investing in a lathe favors operations like threading and turning, whereas a mill better suits drilling, slotting, and complex contouring tasks.

Lathe vs Mill Infographic

productdif.com

productdif.com