A planer is designed to shave off thin layers of wood to achieve uniform thickness across a board, making it ideal for resizing rough or uneven lumber. A jointer, on the other hand, is used to create flat surfaces and straight edges along the length of a board, essential for preparing wood edges for precise joining. Understanding the distinction between a planer and jointer ensures efficient woodworking by providing both dimensioning and flattening capabilities.

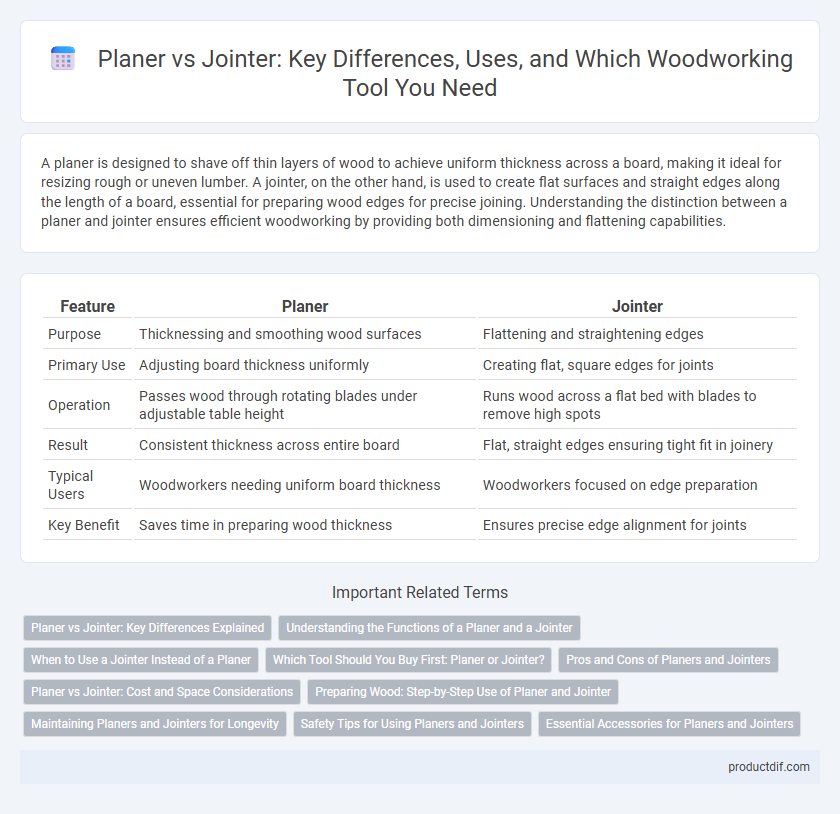

Table of Comparison

| Feature | Planer | Jointer |

|---|---|---|

| Purpose | Thicknessing and smoothing wood surfaces | Flattening and straightening edges |

| Primary Use | Adjusting board thickness uniformly | Creating flat, square edges for joints |

| Operation | Passes wood through rotating blades under adjustable table height | Runs wood across a flat bed with blades to remove high spots |

| Result | Consistent thickness across entire board | Flat, straight edges ensuring tight fit in joinery |

| Typical Users | Woodworkers needing uniform board thickness | Woodworkers focused on edge preparation |

| Key Benefit | Saves time in preparing wood thickness | Ensures precise edge alignment for joints |

Planer vs Jointer: Key Differences Explained

A planer is designed to create uniform thickness across rough lumber by shaving parallel surfaces, while a jointer focuses on flattening and straightening edges to ensure precise 90-degree corners. Planers feature adjustable thickness settings for consistent board dimensions, whereas jointers use flat tables and a cutter head to eliminate warps and crowns. Understanding these core functional differences helps woodworkers select the right tool for surface smoothing versus edge preparation tasks.

Understanding the Functions of a Planer and a Jointer

A planer is designed to create uniform thickness across wooden boards by removing material from the surface, ensuring precise dimensions and smoothness. A jointer flattens and straightens edges and faces of boards, producing perfectly square corners for seamless joins in woodworking projects. Understanding these specific functions helps woodworkers select the appropriate tool for tasks like thickness adjustment or edge preparation, optimizing workflow and craftsmanship quality.

When to Use a Jointer Instead of a Planer

Use a jointer instead of a planer when you need to flatten one face of a rough board or straighten and square edges for accurate joints. A jointer excels at removing twists, cups, and bows, creating a perfectly flat reference surface before further thicknessing. Planers are better suited for uniform thicknessing after the jointer has prepared the initial flat face.

Which Tool Should You Buy First: Planer or Jointer?

Choosing between a planer and a jointer depends on your woodworking priorities; a jointer is essential for flattening and squaring edges, ensuring precise alignment in joints, while a planer quickly smooths and thicknesses boards, enhancing uniformity across surfaces. Investing in a jointer first is advisable if you frequently work with rough or uneven lumber, as it prepares edges for seamless gluing and assembly. For projects requiring consistent thickness and smooth faces, prioritize a planer to streamline board preparation and final finishing.

Pros and Cons of Planers and Jointers

Planers excel at creating uniform thickness across rough lumber, providing smooth surfaces efficiently and preserving material integrity, but they struggle with correcting warped boards. Jointers effectively flatten one face and square edges for precise joinery, though they're limited in thickness adjustment and may require planing afterward for consistent thickness. Choosing between a planer and jointer depends on woodworking needs: planers optimize thickness uniformity while jointers ensure flat, square surfaces for accurate assembly.

Planer vs Jointer: Cost and Space Considerations

Planers generally cost less and require less space compared to jointers, making them ideal for smaller workshops or budget-conscious woodworkers. Jointers are typically more expensive and bulkier due to their larger cutting surface and specialized function of flattening edges. Evaluating project needs and available workspace helps determine whether investing in a planer or jointer is more cost-effective and practical.

Preparing Wood: Step-by-Step Use of Planer and Jointer

Using a planer involves feeding rough lumber through its rollers to achieve consistent thickness and smooth surface, ideal for dimensioning boards quickly. A jointer prepares wood edges by flattening and squaring one face and one edge, ensuring accurate 90-degree angles crucial for seamless joinery. Step-by-step preparation begins with the jointer to create a flat reference edge, followed by the planer to achieve uniform thickness, optimizing wood for precise woodworking projects.

Maintaining Planers and Jointers for Longevity

Regularly cleaning and lubricating the blades and moving parts of planers and jointers prevents rust and ensures smooth operation. Inspecting and replacing worn knives or blades maintains cutting precision and reduces strain on motors. Proper alignment and calibration of the tables and fences extend tool accuracy and overall longevity in woodworking projects.

Safety Tips for Using Planers and Jointers

When using planers and jointers, always wear safety goggles and hearing protection to guard against wood chips and loud noise. Ensure the blades are sharp and properly aligned to prevent kickback and reduce the risk of injury. Maintain a firm grip on the wood and use push blocks or push sticks to keep hands safely away from the cutting area.

Essential Accessories for Planers and Jointers

Essential accessories for planers include carbide replacement blades, dust collection adapters, and precision depth gauges to ensure smooth, accurate thicknessing and efficient debris management. For jointers, crucial accessories encompass helical cutter heads, push blocks, and outfeed table extensions, which enhance safety, extend capacity, and improve surface finish quality. Both tools benefit from regular blade sharpening systems and alignment jigs to maintain optimal performance and prolong tool lifespan.

Planer vs Jointer Infographic

productdif.com

productdif.com