Precision tools are engineered for tasks requiring high accuracy and fine detail, ensuring consistent performance and minimal error. General tools, while versatile and suitable for a broad range of applications, often lack the specialized features needed for intricate or delicate work. Choosing between precision and general tools depends on the specific requirements of the project, with precision tools providing superior control and reliability in demanding situations.

Table of Comparison

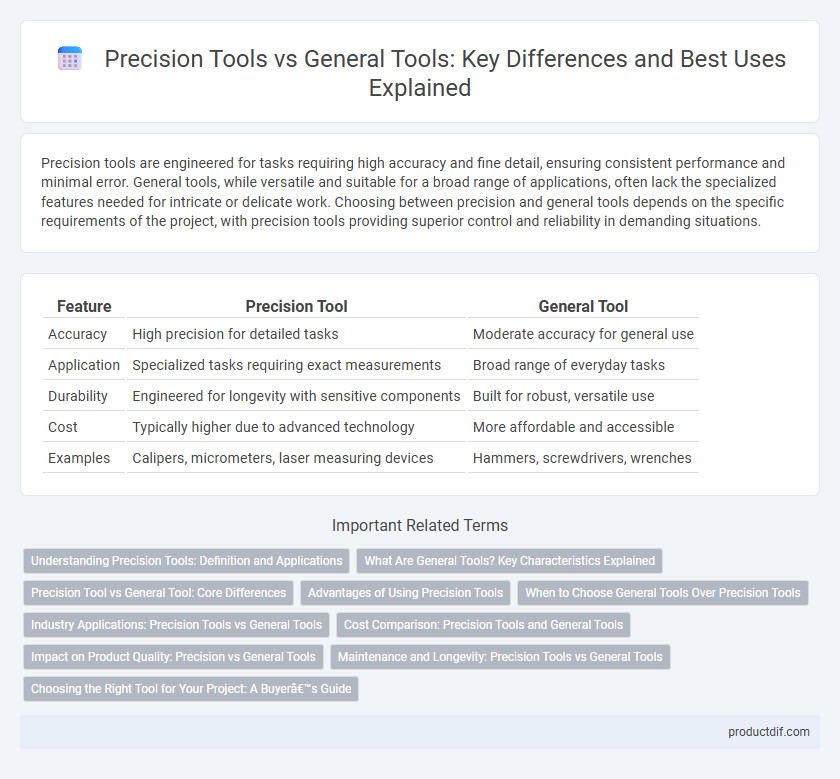

| Feature | Precision Tool | General Tool |

|---|---|---|

| Accuracy | High precision for detailed tasks | Moderate accuracy for general use |

| Application | Specialized tasks requiring exact measurements | Broad range of everyday tasks |

| Durability | Engineered for longevity with sensitive components | Built for robust, versatile use |

| Cost | Typically higher due to advanced technology | More affordable and accessible |

| Examples | Calipers, micrometers, laser measuring devices | Hammers, screwdrivers, wrenches |

Understanding Precision Tools: Definition and Applications

Precision tools are specialized instruments designed for tasks requiring high accuracy and fine detail, such as measuring, cutting, or assembling delicate components in industries like watchmaking, electronics, and aerospace. These tools offer tighter tolerances and enhanced control compared to general tools, ensuring consistency and reducing errors in precision-critical applications. Their use is essential in manufacturing processes where exact measurements and precise manipulation directly impact product quality and performance.

What Are General Tools? Key Characteristics Explained

General tools are versatile instruments designed for a broad range of tasks, offering adaptability across various applications without specialized functions. Key characteristics include multi-functionality, ease of use, and cost-effectiveness, making them ideal for everyday repairs and basic maintenance. Unlike precision tools, general tools prioritize convenience and general utility over high accuracy and specialized measurement.

Precision Tool vs General Tool: Core Differences

Precision tools are engineered for high accuracy and fine detail work, featuring tighter tolerances and specialized materials to ensure exact measurements and cuts. General tools offer versatility and durability for broader applications but lack the specialized calibration and sensitivity required for intricate tasks. The core difference lies in precision tools' capacity for micro-adjustments and consistent performance in demanding environments, unlike general tools designed for robust, everyday use.

Advantages of Using Precision Tools

Precision tools offer unmatched accuracy and consistency, essential for tasks requiring exact measurements and fine details. Using precision tools reduces material waste and improves overall craftsmanship quality, contributing to cost efficiency in manufacturing and repair processes. These tools also enhance productivity by minimizing rework and ensuring reliable, repeatable results in professional and industrial applications.

When to Choose General Tools Over Precision Tools

General tools offer versatility and cost-effectiveness for everyday tasks that do not require high accuracy or specialization. They are ideal for quick fixes, rough work, and scenarios where speed and adaptability are more important than fine detail. Choosing general tools over precision tools benefits projects with broader tolerances or less stringent quality standards.

Industry Applications: Precision Tools vs General Tools

Precision tools are essential in industries requiring high accuracy and fine tolerances, such as aerospace, electronics manufacturing, and medical device production. General tools are commonly used in construction, automotive repair, and household maintenance where versatility is more important than exact measurement. The choice between precision and general tools directly impacts operational efficiency, product quality, and compliance with industry standards.

Cost Comparison: Precision Tools and General Tools

Precision tools typically incur higher initial costs due to advanced manufacturing processes and tighter tolerances required for specialized tasks. General tools offer a more cost-effective option for everyday use but may sacrifice accuracy and durability over time. Investment in precision tools can lead to long-term savings by reducing errors and maintenance frequency in critical applications.

Impact on Product Quality: Precision vs General Tools

Precision tools significantly enhance product quality by delivering high accuracy and consistent performance, minimizing errors and defects during manufacturing processes. General tools, while versatile and cost-effective, often lack the fine tolerance needed for intricate tasks, potentially leading to variability and reduced product reliability. Investing in precision tools ensures tighter quality control, resulting in superior finishes and adherence to exact specifications essential for high-standard production.

Maintenance and Longevity: Precision Tools vs General Tools

Precision tools require meticulous maintenance, including regular calibration and specialized cleaning, to ensure optimal performance and accuracy over time. General tools demand less frequent upkeep but may suffer from faster wear and reduced reliability with heavy use. Investing in precision tools typically results in extended longevity and consistent results, especially in tasks requiring high accuracy.

Choosing the Right Tool for Your Project: A Buyer’s Guide

Precision tools deliver exact measurements and intricate adjustments essential for high-quality craftsmanship, while general tools offer versatility for everyday tasks and broader applications. Selecting the right tool depends on the project's complexity, material requirements, and desired accuracy, ensuring efficiency and optimal results. Investing in precision tools benefits specialized projects requiring tight tolerances, whereas general tools are cost-effective for routine maintenance and standard construction work.

Precision Tool vs General Tool Infographic

productdif.com

productdif.com