CNC machining offers superior precision and flexibility for producing complex metal and plastic parts with tight tolerances, making it ideal for low to medium volume manufacturing. Injection molding excels in high-volume production, delivering consistent and fast output of detailed plastic components with minimal waste. Selecting between CNC machining and injection molding depends on factors such as production volume, material type, and design complexity.

Table of Comparison

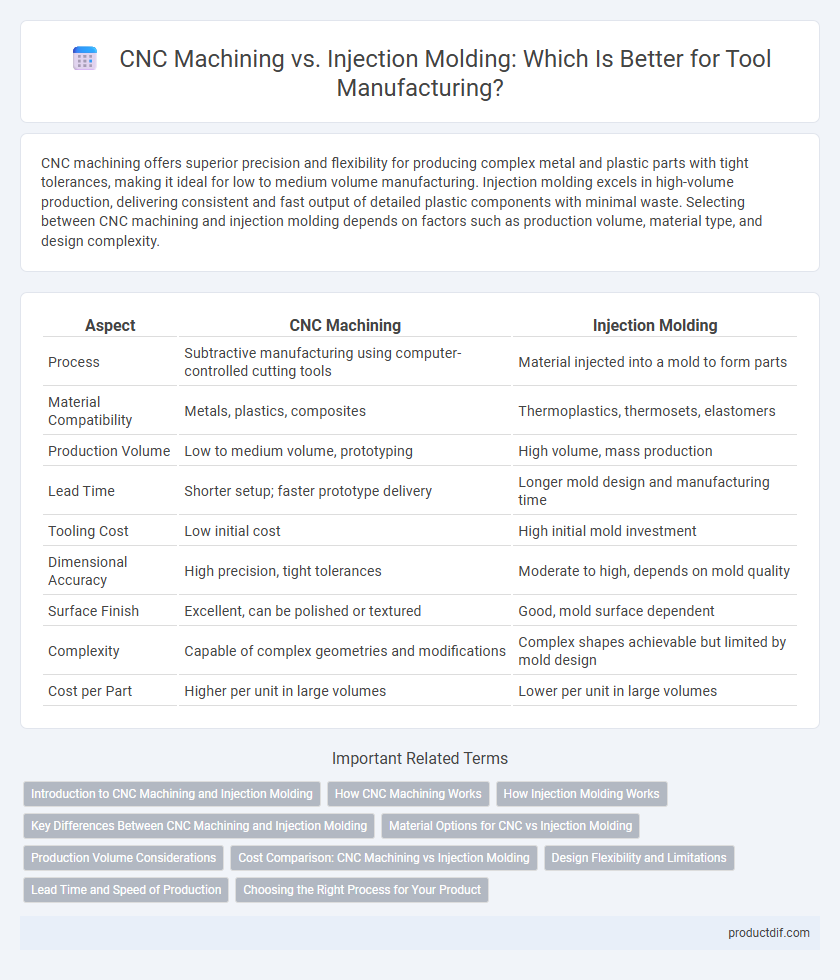

| Aspect | CNC Machining | Injection Molding |

|---|---|---|

| Process | Subtractive manufacturing using computer-controlled cutting tools | Material injected into a mold to form parts |

| Material Compatibility | Metals, plastics, composites | Thermoplastics, thermosets, elastomers |

| Production Volume | Low to medium volume, prototyping | High volume, mass production |

| Lead Time | Shorter setup; faster prototype delivery | Longer mold design and manufacturing time |

| Tooling Cost | Low initial cost | High initial mold investment |

| Dimensional Accuracy | High precision, tight tolerances | Moderate to high, depends on mold quality |

| Surface Finish | Excellent, can be polished or textured | Good, mold surface dependent |

| Complexity | Capable of complex geometries and modifications | Complex shapes achievable but limited by mold design |

| Cost per Part | Higher per unit in large volumes | Lower per unit in large volumes |

Introduction to CNC Machining and Injection Molding

CNC machining utilizes computer-controlled tools to precisely cut and shape materials like metals and plastics, offering high customization and accuracy for prototype and low-to-medium volume production. Injection molding involves injecting molten material into molds to produce large quantities of identical parts efficiently, commonly used for plastic components in automotive and consumer goods industries. Both manufacturing methods serve distinct purposes, with CNC machining excelling in versatility and injection molding optimized for rapid mass production.

How CNC Machining Works

CNC machining operates by using computer numerical control to precisely guide cutting tools that remove material from a solid block, shaping the design according to digital CAD models. This subtractive manufacturing process enables high accuracy and complexity, producing metal or plastic parts with tight tolerances and smooth finishes. CNC machines use various tools such as mills, lathes, and drills, making it ideal for prototyping and low to medium volume production runs where customization and precision are critical.

How Injection Molding Works

Injection molding operates by melting plastic pellets in a heated barrel, then injecting the molten material into a precision-engineered steel mold cavity under high pressure. Once cooled and solidified, the mold opens to release a detailed, consistent part, ideal for large-volume production with tight tolerances. This process enables rapid manufacturing of complex geometries with excellent surface finishes and minimal post-processing requirements.

Key Differences Between CNC Machining and Injection Molding

CNC machining uses subtractive manufacturing to carve parts from solid materials, offering high precision and flexibility for low to medium production volumes. Injection molding involves injecting molten material into a mold cavity, ideal for mass production with consistent repeatability and lower per-unit costs. Material compatibility, tooling expenses, and design complexity also differ significantly, with CNC machining supporting a wider range of materials and quicker prototyping compared to injection molding's high initial mold investment and faster output rates.

Material Options for CNC vs Injection Molding

CNC machining offers a wide range of material options, including metals like aluminum, steel, and titanium, as well as plastics such as ABS, nylon, and polycarbonate, allowing for versatile prototyping and production. Injection molding typically requires thermoplastics like polypropylene, polyethylene, and polystyrene, which are ideal for high-volume manufacturing but have limitations in material variety compared to CNC machining. The choice between CNC machining and injection molding largely depends on the desired material performance, production volume, and complexity of the part.

Production Volume Considerations

CNC machining is ideal for low to medium production volumes due to its flexibility and minimal setup time, enabling rapid prototyping and custom parts manufacturing. Injection molding suits high-volume production runs, as the initial tooling investment is high but amortized by large quantities, resulting in lower per-unit costs. Production volume considerations drive the choice between CNC machining's cost-effective small batch capability and injection molding's efficiency in mass production.

Cost Comparison: CNC Machining vs Injection Molding

CNC machining involves higher initial costs due to complex programming and setup but is cost-effective for low to medium production volumes with greater material variety. Injection molding requires significant upfront investment for mold creation, making it more economical for high-volume production runs with consistent part quality. The break-even point typically occurs between 1,000 to 10,000 units depending on part complexity and production speed.

Design Flexibility and Limitations

CNC machining offers exceptional design flexibility by allowing intricate and precise modifications directly from computer-aided designs, making it ideal for complex prototypes and low-volume production. Injection molding provides limited design flexibility due to the rigid constraints of mold creation, which is cost-effective for high-volume manufacturing but less adaptable to design changes. The initial mold fabrication for injection molding involves high upfront costs and longer lead times, whereas CNC machining supports rapid iteration without significant tooling expenses.

Lead Time and Speed of Production

CNC machining offers rapid prototyping with lead times typically ranging from a few hours to days, making it ideal for low to medium volume production runs requiring quick turnaround. Injection molding requires longer initial lead times due to mold fabrication, often taking several weeks, but it enables significantly faster production speeds for high-volume output once the mold is created. The choice between CNC machining and injection molding depends on balancing the urgency of lead time against the scale of production and per-unit cost efficiency.

Choosing the Right Process for Your Product

CNC machining offers high precision and flexibility ideal for low to medium volume production runs, especially when intricate designs or tight tolerances are required. Injection molding is more cost-effective for high-volume manufacturing, providing faster production rates and consistent part quality after initial mold creation. Selecting the right process depends on factors like production volume, material choice, part complexity, and budget constraints.

CNC machining vs Injection molding Infographic

productdif.com

productdif.com