Forging produces stronger, more durable tools by shaping metal under high pressure, which aligns the grain structure for enhanced toughness and resistance to fatigue. Casting allows complex shapes to be created with minimal machining, ideal for intricate tool components but often results in a less uniform grain structure. Choosing between forging and casting depends on the tool's required strength, precision, and production volume.

Table of Comparison

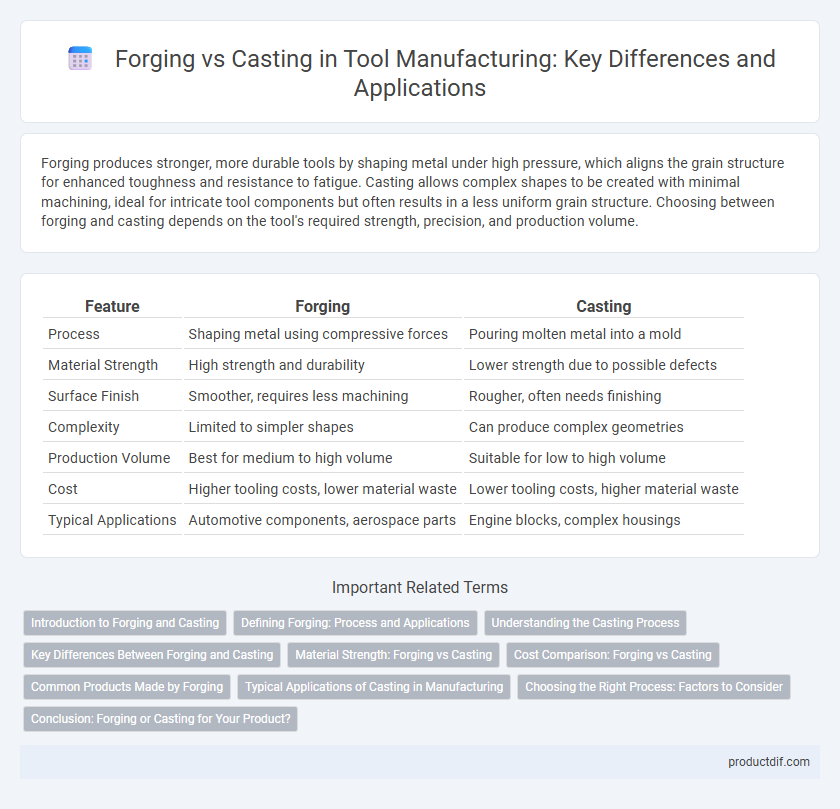

| Feature | Forging | Casting |

|---|---|---|

| Process | Shaping metal using compressive forces | Pouring molten metal into a mold |

| Material Strength | High strength and durability | Lower strength due to possible defects |

| Surface Finish | Smoother, requires less machining | Rougher, often needs finishing |

| Complexity | Limited to simpler shapes | Can produce complex geometries |

| Production Volume | Best for medium to high volume | Suitable for low to high volume |

| Cost | Higher tooling costs, lower material waste | Lower tooling costs, higher material waste |

| Typical Applications | Automotive components, aerospace parts | Engine blocks, complex housings |

Introduction to Forging and Casting

Forging is a manufacturing process involving the shaping of metal using localized compressive forces, typically delivered by a hammer or press, resulting in improved mechanical properties and grain structure. Casting involves pouring molten metal into a mold where it solidifies into the desired shape, suitable for complex geometries and large components. Both processes serve critical roles in tool production, with forging enhancing strength and durability, while casting offers design flexibility.

Defining Forging: Process and Applications

Forging is a manufacturing process that shapes metal using localized compressive forces, typically delivered by a hammer or press, resulting in improved grain structure and mechanical properties. Common applications include automotive components, aerospace parts, and heavy machinery, where strength and durability are critical. This process enhances material reliability by reducing porosity and refining internal grain flow, making forged tools essential for high-stress environments.

Understanding the Casting Process

Casting involves pouring molten metal into a mold where it solidifies into a specific shape, allowing for complex geometries and detailed surface finishes that are difficult to achieve with forging. This process accommodates a wide range of metals such as aluminum, steel, and iron, and is particularly advantageous for producing large or intricate components with consistent dimensional accuracy. Understanding the casting process requires knowledge of mold design, metal melting temperatures, cooling rates, and solidification behavior to minimize defects like porosity and improve mechanical properties.

Key Differences Between Forging and Casting

Forging involves shaping metal through localized compressive forces, resulting in superior grain structure and enhanced mechanical properties compared to casting, where molten metal is poured into molds and solidified. Forged tools typically exhibit higher strength, toughness, and fatigue resistance, while cast tools offer greater design flexibility and complex geometries. The choice between forging and casting depends on application requirements such as strength, durability, and production volume.

Material Strength: Forging vs Casting

Forging produces tools with superior material strength due to the alignment of metal grain structures under intense pressure, resulting in enhanced toughness and resistance to wear. Casting can introduce internal defects such as porosity and shrinkage, which reduce the overall durability and mechanical integrity of the tool. Forged components typically exhibit higher tensile strength and fatigue resistance compared to cast counterparts, making them ideal for high-stress applications.

Cost Comparison: Forging vs Casting

Forging typically incurs higher initial costs due to the need for specialized equipment and skilled labor, but it offers superior mechanical properties and reduced material waste, which can lower long-term expenses. Casting usually has lower upfront tooling and production costs, making it more economical for complex shapes and large batch production despite potential porosity and lower strength. Evaluating total cost efficiency depends on factors such as part complexity, production volume, material selection, and performance requirements.

Common Products Made by Forging

Common products made by forging include automotive components such as crankshafts, connecting rods, and gears, which require enhanced strength and durability. Industrial tools like wrenches, hammers, and pliers are also forged to ensure high performance under stress. Forging is favored for parts subjected to heavy loads and impact due to its ability to create fine grain structures and superior mechanical properties.

Typical Applications of Casting in Manufacturing

Casting is widely used in manufacturing for producing complex shapes and large components such as engine blocks, pump housings, and aerospace parts. This process is favored for creating intricate geometries and internal cavities that would be difficult or costly to achieve through forging or machining. Typical applications include automotive industry parts, heavy machinery components, and decorative metal items where precision and material efficiency are critical.

Choosing the Right Process: Factors to Consider

Selecting between forging and casting depends on factors such as mechanical strength requirements, production volume, and material properties. Forging offers superior grain structure and strength for high-stress applications, while casting allows complex shapes and cost-effective manufacturing for intricate designs. Consider elements like dimensional accuracy, surface finish, and post-processing needs to determine the optimal manufacturing process.

Conclusion: Forging or Casting for Your Product?

Forging produces tools with superior strength, durability, and fatigue resistance due to the refined grain structure from mechanical deformation, making it ideal for high-stress applications. Casting offers greater design flexibility and cost-effectiveness for complex shapes and low-volume production, though with slightly lower mechanical properties. Selecting forging or casting depends on your product's performance requirements, desired geometry, and production scale to optimize strength, precision, and manufacturing efficiency.

Forging vs Casting Infographic

productdif.com

productdif.com