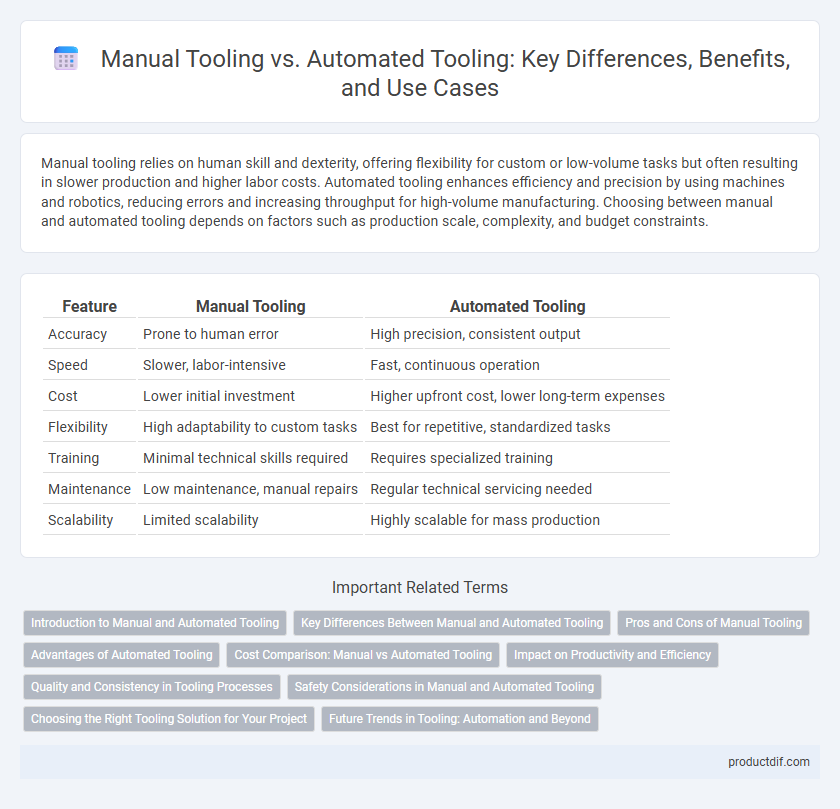

Manual tooling relies on human skill and dexterity, offering flexibility for custom or low-volume tasks but often resulting in slower production and higher labor costs. Automated tooling enhances efficiency and precision by using machines and robotics, reducing errors and increasing throughput for high-volume manufacturing. Choosing between manual and automated tooling depends on factors such as production scale, complexity, and budget constraints.

Table of Comparison

| Feature | Manual Tooling | Automated Tooling |

|---|---|---|

| Accuracy | Prone to human error | High precision, consistent output |

| Speed | Slower, labor-intensive | Fast, continuous operation |

| Cost | Lower initial investment | Higher upfront cost, lower long-term expenses |

| Flexibility | High adaptability to custom tasks | Best for repetitive, standardized tasks |

| Training | Minimal technical skills required | Requires specialized training |

| Maintenance | Low maintenance, manual repairs | Regular technical servicing needed |

| Scalability | Limited scalability | Highly scalable for mass production |

Introduction to Manual and Automated Tooling

Manual tooling requires skilled operators to handle tools and equipment directly, offering flexibility and precision in low-volume or custom production. Automated tooling employs machines and robotics to perform repetitive tasks with high speed and consistency, ideal for large-scale manufacturing. Both approaches optimize efficiency by aligning tool usage with specific production needs and complexity.

Key Differences Between Manual and Automated Tooling

Manual tooling requires direct human intervention to operate, involving physical tools and skills for tasks such as shaping, cutting, or assembling. Automated tooling uses machinery and computer-controlled systems to perform repetitive or complex operations, increasing precision, speed, and consistency. Key differences include efficiency, repeatability, labor intensity, and initial investment costs, with automated tooling reducing manual labor but requiring higher upfront expenses and technical maintenance.

Pros and Cons of Manual Tooling

Manual tooling allows for precise control and customization in small-scale or intricate tasks, making it ideal for prototyping and low-volume production. The main drawbacks include higher labor costs, slower production speeds, and increased potential for human error compared to automated tooling. Despite these limitations, manual tools offer greater flexibility and easier adaptation to changes in design or process.

Advantages of Automated Tooling

Automated tooling increases production speed by consistently performing repetitive tasks with high precision, minimizing human error and reducing cycle times. It enhances scalability and efficiency by enabling continuous operation without fatigue, leading to higher throughput and lower labor costs. Integration with advanced software systems allows real-time monitoring and data analytics, improving process optimization and maintenance scheduling.

Cost Comparison: Manual vs Automated Tooling

Manual tooling typically incurs lower initial costs due to minimal equipment investment but results in higher labor expenses and longer production times. Automated tooling demands significant upfront capital for machinery and programming but reduces ongoing labor costs and increases efficiency, leading to lower per-unit expenses in high-volume production. Cost comparison reveals manual tooling suits low-volume or prototype runs, while automated tooling offers cost advantages for large-scale manufacturing through economies of scale.

Impact on Productivity and Efficiency

Manual tooling relies heavily on skilled labor, often leading to slower production rates and higher chances of human error, which decreases overall productivity. Automated tooling integrates advanced machinery and software, significantly enhancing efficiency by reducing cycle times and improving precision. This transition from manual to automated systems typically results in substantial cost savings and increased output quality within manufacturing processes.

Quality and Consistency in Tooling Processes

Manual tooling relies on skilled operators to maintain quality, but variability in human performance can lead to inconsistencies in production outcomes. Automated tooling leverages precise machinery and controlled programming, ensuring consistent quality by minimizing human error and standardizing processes. Enhanced repeatability and real-time monitoring in automated systems significantly improve product uniformity and reduce defect rates across manufacturing cycles.

Safety Considerations in Manual and Automated Tooling

Manual tooling demands rigorous adherence to personal protective equipment and safe handling protocols due to direct human interaction, increasing the risk of injury from sharp edges, repetitive motions, and heavy lifting. Automated tooling integrates safety sensors, emergency stop mechanisms, and enclosure systems, significantly reducing operator exposure to hazards and minimizing accidents caused by human error. Regular maintenance and safety audits are critical in both approaches to ensure tools operate within safety standards and prevent malfunction-related injuries.

Choosing the Right Tooling Solution for Your Project

Selecting the right tooling solution depends on project complexity, budget, and timeline, where manual tooling provides flexibility and precision for small-scale or customized tasks, while automated tooling offers efficiency and consistency for high-volume production. Consider factors such as production volume, skill level of operators, and long-term maintenance costs to determine the optimal balance between manual and automated processes. Evaluating these criteria ensures enhanced productivity, reduced errors, and cost-effective resource allocation tailored to your project's specific requirements.

Future Trends in Tooling: Automation and Beyond

Future trends in tooling emphasize the integration of advanced automation technologies such as robotics, AI-driven systems, and IoT connectivity to enhance precision and efficiency. Manual tooling remains essential for customization and flexibility, but automated tooling increasingly dominates industries by reducing cycle times and minimizing human error. Emerging developments include adaptive tooling systems capable of real-time adjustments and predictive maintenance powered by machine learning algorithms.

Manual tooling vs Automated tooling Infographic

productdif.com

productdif.com