Carpentry tools are specifically designed for woodworking tasks, featuring precision instruments such as chisels, saws, and planes that shape and join wood efficiently. Masonry tools, on the other hand, are built to handle harder materials like brick, stone, and concrete, with items such as trowels, hammers, and masonry saws that enable cutting, shaping, and setting these materials securely. Choosing the right tool ensures durability and accuracy in construction projects based on the material involved.

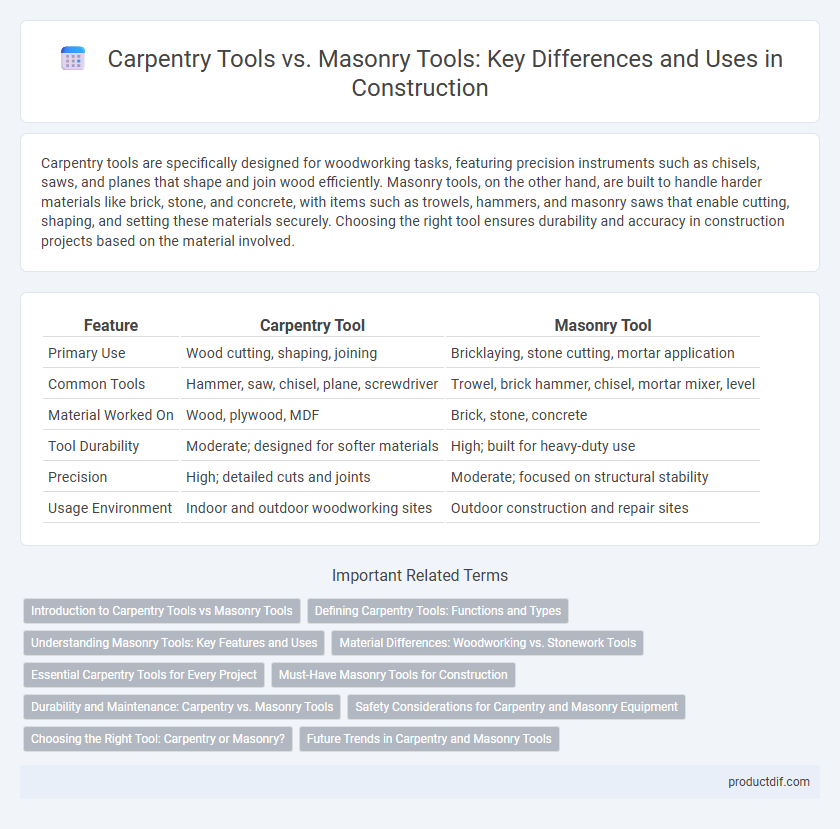

Table of Comparison

| Feature | Carpentry Tool | Masonry Tool |

|---|---|---|

| Primary Use | Wood cutting, shaping, joining | Bricklaying, stone cutting, mortar application |

| Common Tools | Hammer, saw, chisel, plane, screwdriver | Trowel, brick hammer, chisel, mortar mixer, level |

| Material Worked On | Wood, plywood, MDF | Brick, stone, concrete |

| Tool Durability | Moderate; designed for softer materials | High; built for heavy-duty use |

| Precision | High; detailed cuts and joints | Moderate; focused on structural stability |

| Usage Environment | Indoor and outdoor woodworking sites | Outdoor construction and repair sites |

Introduction to Carpentry Tools vs Masonry Tools

Carpentry tools such as saws, chisels, and hammers are specifically designed for working with wood, allowing precise cuts, shaping, and joining. Masonry tools, including trowels, brick hammers, and levels, are engineered to handle stone, brick, and concrete materials for constructing durable structures. Understanding the specific functions and materials each tool targets is crucial for selecting the right equipment for construction and renovation projects.

Defining Carpentry Tools: Functions and Types

Carpentry tools are specifically designed for woodworking tasks, including shaping, cutting, and joining wood materials. Common types of carpentry tools include saws, chisels, hammers, planes, and measuring instruments such as tape measures and squares, each serving specialized functions in construction and furniture making. Unlike masonry tools, which are tailored for stone, brick, or concrete work, carpentry tools emphasize precision and versatility for wood manipulation and assembly.

Understanding Masonry Tools: Key Features and Uses

Masonry tools are designed for working with stone, brick, and concrete, featuring robust materials and specialized shapes such as trowels, chisels, and mason hammers that facilitate cutting, shaping, and finishing masonry surfaces. These tools often have hardened steel tips for durability and precise control, essential for tasks like laying bricks, carving stone, or smoothing mortar. Understanding the specific uses of masonry tools ensures proper application and efficiency, setting them apart from carpentry tools which are tailored for woodwork and joinery.

Material Differences: Woodworking vs. Stonework Tools

Carpentry tools are primarily designed with wood materials in mind, featuring sharper blades and finer teeth to handle softer textures and delicate grain patterns in woodworking. Masonry tools are constructed from robust metals such as steel and tungsten carbide to withstand the hardness and abrasiveness of stone, concrete, and brick surfaces. Differences in design and material composition directly impact durability and efficiency when cutting, shaping, or chiseling wood versus stone.

Essential Carpentry Tools for Every Project

Essential carpentry tools include a claw hammer, tape measure, speed square, chisels, and a power drill, designed for precise wood cutting, measuring, and assembling. These tools are optimized for woodworking tasks, offering accuracy and efficiency when building furniture, framing, or cabinetry. Unlike masonry tools such as trowels and masonry hammers, carpentry tools prioritize wood compatibility and fine detail work.

Must-Have Masonry Tools for Construction

Essential masonry tools for construction include trowels, which are critical for spreading and shaping mortar, and masonry hammers, designed to break and chip bricks or stones with precision. Levels and chisels ensure accurate alignment and clean cuts, improving the structural integrity of walls and surfaces. Mortar mixers speed up preparation, while wheelbarrows and shovels facilitate efficient transport and handling of heavy materials on-site.

Durability and Maintenance: Carpentry vs. Masonry Tools

Carpentry tools typically feature wooden or plastic handles, requiring regular maintenance such as oiling and tightening to ensure durability, while masonry tools are constructed from heavy-duty steel or iron designed to withstand abrasive materials and harsh conditions. The durability of masonry tools often surpasses carpentry tools due to their resistance to chipping and corrosion, making them ideal for concrete and stone work. Routine sharpening and cleaning extend the lifespan of both tool types, but masonry tools demand less frequent maintenance despite their rugged use.

Safety Considerations for Carpentry and Masonry Equipment

Carpentry tools, such as saws and chisels, require safety measures including the use of sharp blade guards, proper hand positioning, and wearing protective eyewear to prevent splinters and debris injuries. Masonry equipment, like trowels and power mixers, demands additional precautions such as dust masks to avoid inhalation of silica dust and reinforced gloves to protect against abrasive materials. Ensuring regular maintenance and proper training for the specific hazards of each tool type significantly reduces the risk of accidents on site.

Choosing the Right Tool: Carpentry or Masonry?

Choosing the right tool depends on the specific material and task involved; carpentry tools like saws, chisels, and planes are designed for shaping wood with precision, while masonry tools such as trowels, brick hammers, and mortar mixers are optimized for handling brick, stone, and concrete. Using carpentry tools on masonry materials can lead to damage and inefficient work, whereas masonry tools are engineered to withstand the hardness and abrasiveness of stone surfaces. Selecting the appropriate tool ensures durability, safety, and the quality of the finished construction or woodworking project.

Future Trends in Carpentry and Masonry Tools

Future trends in carpentry tools emphasize increased integration of smart technology, such as IoT-enabled measuring devices and automated cutting systems, improving precision and efficiency on job sites. Masonry tools are advancing with innovations like laser-guided levels and energy-efficient power tools, enhancing accuracy and reducing physical strain for workers. Both fields are moving towards sustainable materials and cordless solutions that offer greater mobility and environmental benefits.

Carpentry Tool vs Masonry Tool Infographic

productdif.com

productdif.com