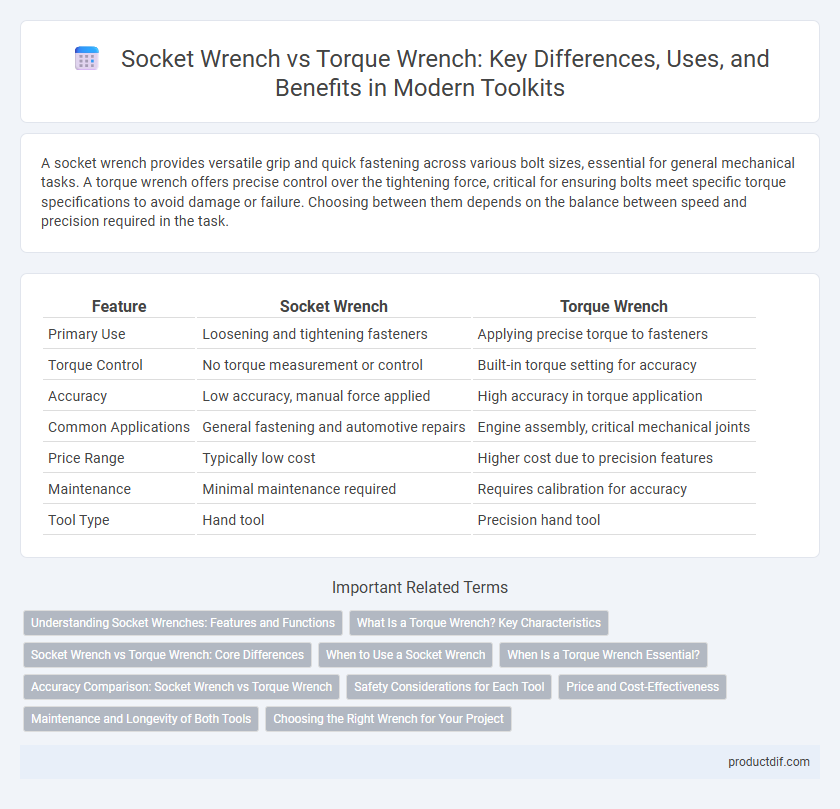

A socket wrench provides versatile grip and quick fastening across various bolt sizes, essential for general mechanical tasks. A torque wrench offers precise control over the tightening force, critical for ensuring bolts meet specific torque specifications to avoid damage or failure. Choosing between them depends on the balance between speed and precision required in the task.

Table of Comparison

| Feature | Socket Wrench | Torque Wrench |

|---|---|---|

| Primary Use | Loosening and tightening fasteners | Applying precise torque to fasteners |

| Torque Control | No torque measurement or control | Built-in torque setting for accuracy |

| Accuracy | Low accuracy, manual force applied | High accuracy in torque application |

| Common Applications | General fastening and automotive repairs | Engine assembly, critical mechanical joints |

| Price Range | Typically low cost | Higher cost due to precision features |

| Maintenance | Minimal maintenance required | Requires calibration for accuracy |

| Tool Type | Hand tool | Precision hand tool |

Understanding Socket Wrenches: Features and Functions

Socket wrenches feature a ratcheting mechanism that allows users to tighten or loosen fasteners efficiently without removing the tool from the bolt head. Available in various drive sizes such as 1/4-inch, 3/8-inch, and 1/2-inch, socket wrenches accommodate a wide range of bolt sizes and applications. Their versatility makes them essential for general fastening tasks, contrasting with torque wrenches that provide precise torque measurement for critical tightening.

What Is a Torque Wrench? Key Characteristics

A torque wrench is a precision tool designed to apply a specific amount of torque to fasteners, ensuring accurate tightening without overloading. Key characteristics include a calibrated scale for torque measurement, a ratcheting mechanism for ease of use, and adjustable settings to accommodate various torque requirements. Unlike a socket wrench, which primarily provides leverage for loosening or tightening, a torque wrench guarantees the correct tension, critical in automotive and mechanical applications.

Socket Wrench vs Torque Wrench: Core Differences

Socket wrenches provide versatility for tightening and loosening fasteners with interchangeable sockets, enabling efficient work on various bolt sizes. Torque wrenches specialize in applying precise torque to fasteners, preventing overtightening and ensuring manufacturer-specified tension. The core difference lies in torque control, with socket wrenches offering general use and torque wrenches delivering accuracy critical for automotive and mechanical applications.

When to Use a Socket Wrench

A socket wrench is ideal for general fastening tasks where speed and efficiency are needed, such as loosening or tightening bolts and nuts in automotive repair or machinery maintenance. It provides convenience and leverage without the need for precise torque settings, making it perfect for quick adjustments and assembly work. Use a socket wrench when torque accuracy is not critical and rapid turning is preferred.

When Is a Torque Wrench Essential?

A torque wrench is essential when precise tightening of fasteners to a specified torque value is required to ensure safety and prevent damage. In automotive repair, machinery assembly, and critical construction projects, using a torque wrench guarantees bolts and nuts meet manufacturer specifications and avoid over-torquing. Unlike a socket wrench that only applies rotational force, a torque wrench provides accurate torque measurement, crucial for maintaining structural integrity and performance.

Accuracy Comparison: Socket Wrench vs Torque Wrench

Torque wrenches provide superior accuracy compared to socket wrenches by delivering precise torque control essential for tightening bolts to manufacturer specifications. Socket wrenches offer flexibility and speed but lack built-in mechanisms to measure torque, making them less suitable for applications requiring exact torque values. Using a torque wrench ensures consistent tension and prevents over-tightening or under-tightening, reducing the risk of damage and enhancing safety.

Safety Considerations for Each Tool

Socket wrenches offer versatility and speed but require proper hand positioning to prevent slippage and injury during high-torque applications. Torque wrenches ensure precise tightening, reducing the risk of over-torquing fasteners and potential equipment damage, enhancing overall safety in assembly tasks. Using the appropriate tool according to specified torque settings is critical to maintaining mechanical integrity and preventing accidents.

Price and Cost-Effectiveness

Socket wrenches typically cost between $15 and $50, making them an affordable choice for general tightening and loosening tasks, while torque wrenches range from $50 to over $200, reflecting their precision and specialized function. Despite the higher upfront price, torque wrenches offer superior accuracy that prevents over-tightening or under-tightening, reducing costly damage to bolts and machinery. For frequent users needing precise torque measurement, the long-term cost-effectiveness of a torque wrench outweighs the initial investment compared to standard socket wrenches.

Maintenance and Longevity of Both Tools

Regular calibration and proper storage significantly enhance the maintenance and longevity of torque wrenches by preventing accuracy drift and mechanical wear. Socket wrenches require routine cleaning and lubrication of the ratchet mechanism to avoid rust and ensure smooth operation over time. Both tools benefit from using manufacturer-recommended parts and avoiding overloading to maintain optimal performance and extend their service life.

Choosing the Right Wrench for Your Project

Choosing the right wrench depends on the task requirements: socket wrenches provide versatility for loosening and tightening bolts with adjustable sockets, while torque wrenches ensure precise torque application to avoid over-tightening and damage. For automotive repairs and machinery maintenance where accurate torque specifications are critical, a torque wrench is essential. In general mechanical work involving various fastener sizes, a socket wrench set offers greater flexibility and efficiency.

socket wrench vs torque wrench Infographic

productdif.com

productdif.com