An adjustable wrench offers versatility by enabling users to change jaw sizes for various bolt and nut dimensions, reducing the need for multiple tools. In contrast, a fixed wrench provides a more secure, non-slip fit tailored to a specific size, enhancing torque application and durability. Choosing between adjustable and fixed wrenches depends on the specific task requirements and the balance between convenience and precision.

Table of Comparison

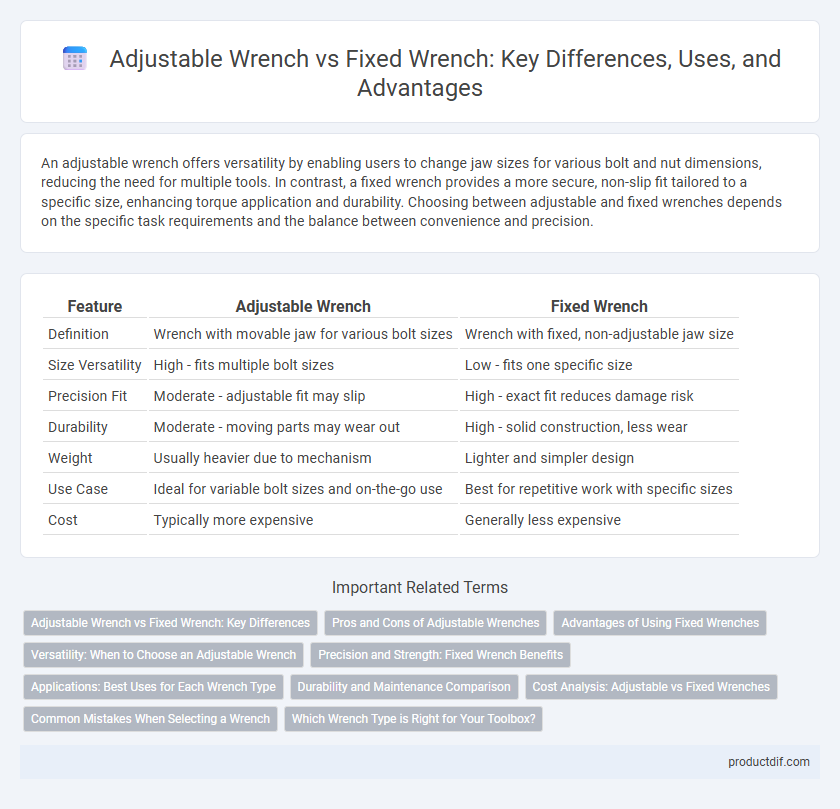

| Feature | Adjustable Wrench | Fixed Wrench |

|---|---|---|

| Definition | Wrench with movable jaw for various bolt sizes | Wrench with fixed, non-adjustable jaw size |

| Size Versatility | High - fits multiple bolt sizes | Low - fits one specific size |

| Precision Fit | Moderate - adjustable fit may slip | High - exact fit reduces damage risk |

| Durability | Moderate - moving parts may wear out | High - solid construction, less wear |

| Weight | Usually heavier due to mechanism | Lighter and simpler design |

| Use Case | Ideal for variable bolt sizes and on-the-go use | Best for repetitive work with specific sizes |

| Cost | Typically more expensive | Generally less expensive |

Adjustable Wrench vs Fixed Wrench: Key Differences

An adjustable wrench features a movable jaw that allows it to fit various bolt sizes, providing versatility in different applications. In contrast, a fixed wrench has a fixed jaw size designed for specific fasteners, delivering greater strength and a better fit for repetitive tasks. Selecting between these tools depends on the need for flexibility versus precision and torque.

Pros and Cons of Adjustable Wrenches

Adjustable wrenches offer versatility for various bolt sizes, reducing the need to carry multiple fixed wrenches and saving space in toolkits. However, they may lack the precise grip and torque of fixed wrenches, increasing the risk of rounding off fasteners under high stress. The adjustable mechanism can also wear out over time, potentially compromising performance and durability compared to the solid construction of fixed wrenches.

Advantages of Using Fixed Wrenches

Fixed wrenches provide superior strength and durability due to their solid construction, making them ideal for heavy-duty tasks requiring high torque. Their precise fit on fasteners minimizes the risk of rounding nuts or bolts, ensuring secure and efficient tightening. Fixed wrenches also offer consistent leverage without the potential slippage common in adjustable models, enhancing user safety and control during use.

Versatility: When to Choose an Adjustable Wrench

An adjustable wrench offers superior versatility compared to a fixed wrench by accommodating various bolt and nut sizes, reducing the need to carry multiple tools. It is ideal for tasks requiring quick size adjustments or when working with hardware of differing dimensions. Fixed wrenches provide a more secure fit and higher torque but lack the adaptability required for mixed-size jobs.

Precision and Strength: Fixed Wrench Benefits

A fixed wrench offers superior strength due to its solid, one-piece design that minimizes flex under high torque, making it ideal for heavy-duty applications. Precision is enhanced as the fixed wrench maintains a consistent jaw size, reducing the risk of slipping or rounding off fasteners. This reliability ensures maximum torque transfer and durability in demanding mechanical tasks.

Applications: Best Uses for Each Wrench Type

Adjustable wrenches offer versatility for various bolt sizes, making them ideal for general maintenance and repair tasks where multiple fastener sizes are encountered. Fixed wrenches provide a secure fit and greater torque for specific bolt sizes, enhancing performance in automotive work and precision machinery assembly. Choosing the right wrench depends on the application; adjustable wrenches excel in flexibility, while fixed wrenches ensure strength and reliability in repetitive tasks.

Durability and Maintenance Comparison

Adjustable wrenches feature a movable jaw allowing versatility across multiple bolt sizes, which introduces more wear points than fixed wrenches. Fixed wrenches, typically made from high-grade alloy steel, offer superior durability due to their solid, one-piece construction that resists bending and wear over time. Maintenance of adjustable wrenches requires regular lubrication and jaw tightening to ensure smooth operation, whereas fixed wrenches demand minimal upkeep, primarily focused on cleaning and rust prevention.

Cost Analysis: Adjustable vs Fixed Wrenches

Adjustable wrenches typically offer greater cost efficiency due to their versatility, reducing the need to purchase multiple fixed wrench sizes. Fixed wrenches, while often cheaper per unit, may lead to higher overall expenses when a full set is required for varied applications. Assessing long-term usage and project scope helps determine the most economically viable option between adjustable and fixed wrenches.

Common Mistakes When Selecting a Wrench

Choosing an adjustable wrench instead of a fixed wrench often leads to slipping or damaging fasteners due to improper jaw fit and insufficient grip pressure. Using a fixed wrench on irregular or varying sizes can cause rounding of bolt heads, resulting from forcing the wrong tool size. Selecting the wrong type of wrench without considering the torque requirements and accessibility can cause tool wear and compromised safety.

Which Wrench Type is Right for Your Toolbox?

An adjustable wrench offers versatility by fitting a range of bolt sizes, making it ideal for a toolbox needing flexibility and fewer tools, while fixed wrenches provide optimal strength and precision for specific bolt sizes, ensuring reliable torque and less risk of slip. Choose an adjustable wrench for general maintenance and diverse tasks, whereas fixed wrenches are better suited for professional work requiring durability and consistent performance. Assess the types of projects you handle most often to determine whether the convenience of adjustability or the specialized reliability of fixed wrenches best fits your toolbox needs.

adjustable wrench vs fixed wrench Infographic

productdif.com

productdif.com