Stainless steel fasteners offer superior corrosion resistance and durability, making them ideal for outdoor and marine applications where exposure to moisture and chemicals is common. Carbon steel fasteners provide higher strength and are more cost-effective for indoor or dry environments but require protective coatings to prevent rusting. Selecting between stainless steel and carbon steel fasteners depends on the specific environmental conditions and mechanical requirements of the project.

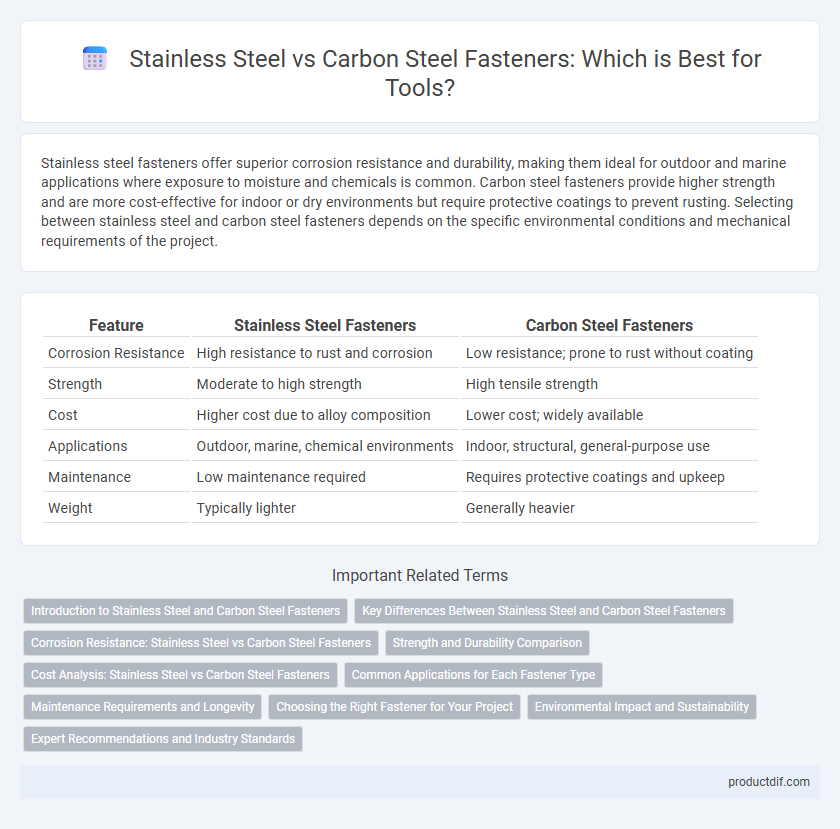

Table of Comparison

| Feature | Stainless Steel Fasteners | Carbon Steel Fasteners |

|---|---|---|

| Corrosion Resistance | High resistance to rust and corrosion | Low resistance; prone to rust without coating |

| Strength | Moderate to high strength | High tensile strength |

| Cost | Higher cost due to alloy composition | Lower cost; widely available |

| Applications | Outdoor, marine, chemical environments | Indoor, structural, general-purpose use |

| Maintenance | Low maintenance required | Requires protective coatings and upkeep |

| Weight | Typically lighter | Generally heavier |

Introduction to Stainless Steel and Carbon Steel Fasteners

Stainless steel fasteners offer superior corrosion resistance, making them ideal for applications exposed to moisture or chemicals, while carbon steel fasteners provide higher strength at a lower cost but require protective coatings to prevent rust. Common stainless steel grades such as 304 and 316 resist oxidation and maintain durability in harsh environments, whereas carbon steel fasteners are often used in construction and machinery where environmental exposure is limited. Selecting between stainless steel and carbon steel fasteners depends on factors such as mechanical strength requirements, environmental conditions, and budget constraints.

Key Differences Between Stainless Steel and Carbon Steel Fasteners

Stainless steel fasteners offer superior corrosion resistance due to their chromium content, making them ideal for marine and outdoor applications, whereas carbon steel fasteners provide higher tensile strength and are typically more cost-effective for interior or dry environments. Carbon steel fasteners require protective coatings to resist rust, while stainless steel fasteners maintain durability without additional treatments. The choice between these fasteners depends on environmental exposure, mechanical strength requirements, and budget considerations.

Corrosion Resistance: Stainless Steel vs Carbon Steel Fasteners

Stainless steel fasteners outperform carbon steel fasteners in corrosion resistance due to their chromium content, which forms a passive oxide layer protecting against rust and environmental damage. Carbon steel fasteners are prone to oxidation and require protective coatings like zinc plating to resist corrosion in moist or outdoor environments. For applications exposed to harsh weather conditions or chemicals, stainless steel fasteners provide longer durability and reduced maintenance costs.

Strength and Durability Comparison

Stainless steel fasteners offer superior corrosion resistance and maintain strength in harsh environments, making them ideal for outdoor and marine applications. Carbon steel fasteners provide higher tensile strength but are more prone to rust and wear, reducing durability without protective coatings. Choosing between them depends on balancing the need for maximum strength versus long-term durability in specific environmental conditions.

Cost Analysis: Stainless Steel vs Carbon Steel Fasteners

Stainless steel fasteners typically incur higher upfront costs due to their corrosion resistance and durability, making them ideal for environments exposed to moisture or chemicals. Carbon steel fasteners, while more cost-effective initially, may require frequent replacement or protective coatings to prevent rust, increasing long-term expenses. Evaluating total lifecycle costs reveals that stainless steel fasteners often provide better value in applications where longevity and minimal maintenance are critical.

Common Applications for Each Fastener Type

Stainless steel fasteners are widely used in marine, chemical processing, and food industries due to their corrosion resistance and durability in harsh environments. Carbon steel fasteners are commonly applied in construction, automotive manufacturing, and machinery assembly where high strength and cost-effectiveness are essential. Choosing between these fastener types depends on exposure to moisture, strength requirements, and environmental conditions.

Maintenance Requirements and Longevity

Stainless steel fasteners offer superior corrosion resistance, significantly reducing maintenance requirements compared to carbon steel fasteners, which are prone to rust and require regular treatment or replacement. The inherent durability of stainless steel fasteners ensures extended longevity in harsh environments, making them ideal for outdoor or marine applications. Carbon steel fasteners, while cost-effective, tend to have a shorter lifespan due to their susceptibility to corrosion and wear.

Choosing the Right Fastener for Your Project

Stainless steel fasteners offer superior corrosion resistance and durability, making them ideal for outdoor or high-moisture environments. Carbon steel fasteners provide higher strength at a lower cost but require protective coatings to prevent rust in exposed conditions. Selecting the right fastener depends on environmental exposure, load requirements, and budget constraints to ensure long-lasting performance and safety.

Environmental Impact and Sustainability

Stainless steel fasteners exhibit superior corrosion resistance, significantly extending their lifecycle and reducing environmental waste compared to carbon steel fasteners, which are more prone to rust and degradation. The recyclability of stainless steel further enhances sustainability by lowering the demand for virgin raw materials and minimizing resource extraction impacts. Carbon steel fasteners, while often cheaper, tend to require more frequent replacement, leading to higher environmental costs over time.

Expert Recommendations and Industry Standards

Experts recommend stainless steel fasteners for corrosion resistance, especially in marine and chemical environments, aligning with industry standards such as ASTM A276 and A479. Carbon steel fasteners, compliant with ASTM A307 and A325, are preferred for applications requiring high tensile strength and cost-effectiveness in dry, non-corrosive settings. Proper selection based on ASTM and ISO guidelines ensures durability, safety, and performance in various industrial applications.

Stainless Steel Fasteners vs Carbon Steel Fasteners Infographic

productdif.com

productdif.com