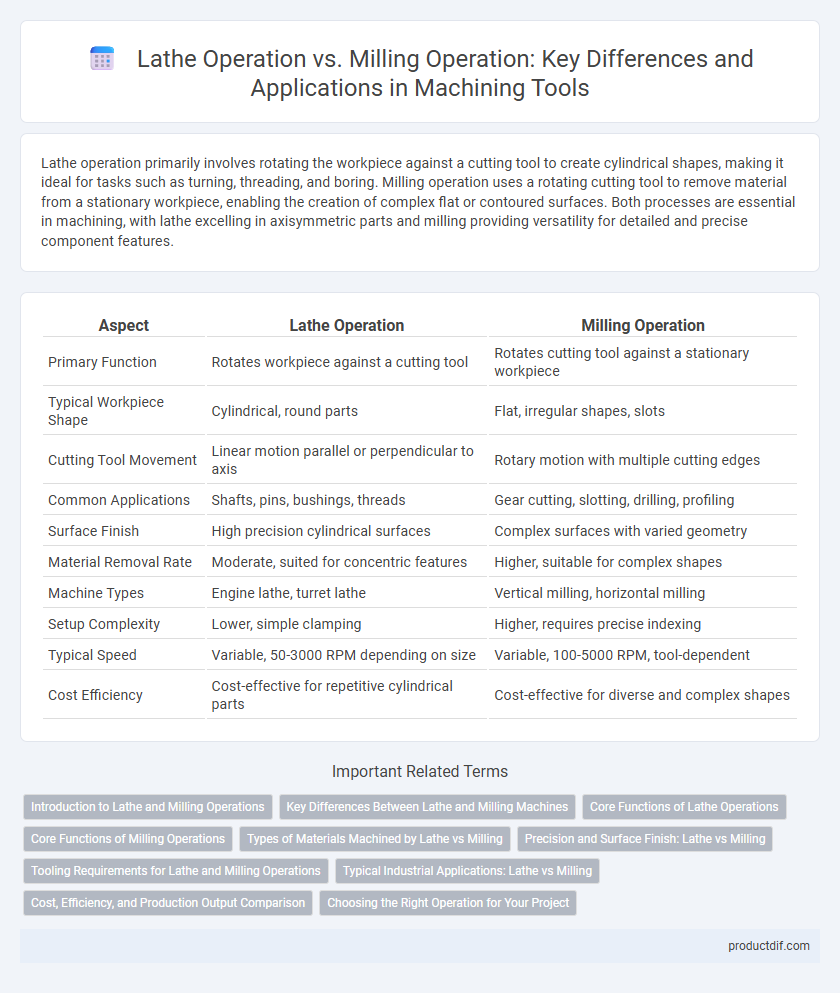

Lathe operation primarily involves rotating the workpiece against a cutting tool to create cylindrical shapes, making it ideal for tasks such as turning, threading, and boring. Milling operation uses a rotating cutting tool to remove material from a stationary workpiece, enabling the creation of complex flat or contoured surfaces. Both processes are essential in machining, with lathe excelling in axisymmetric parts and milling providing versatility for detailed and precise component features.

Table of Comparison

| Aspect | Lathe Operation | Milling Operation |

|---|---|---|

| Primary Function | Rotates workpiece against a cutting tool | Rotates cutting tool against a stationary workpiece |

| Typical Workpiece Shape | Cylindrical, round parts | Flat, irregular shapes, slots |

| Cutting Tool Movement | Linear motion parallel or perpendicular to axis | Rotary motion with multiple cutting edges |

| Common Applications | Shafts, pins, bushings, threads | Gear cutting, slotting, drilling, profiling |

| Surface Finish | High precision cylindrical surfaces | Complex surfaces with varied geometry |

| Material Removal Rate | Moderate, suited for concentric features | Higher, suitable for complex shapes |

| Machine Types | Engine lathe, turret lathe | Vertical milling, horizontal milling |

| Setup Complexity | Lower, simple clamping | Higher, requires precise indexing |

| Typical Speed | Variable, 50-3000 RPM depending on size | Variable, 100-5000 RPM, tool-dependent |

| Cost Efficiency | Cost-effective for repetitive cylindrical parts | Cost-effective for diverse and complex shapes |

Introduction to Lathe and Milling Operations

Lathe operation involves rotating the workpiece on a spindle to perform cutting, shaping, or drilling using a stationary cutting tool, suitable for producing cylindrical parts. Milling operation uses a rotating multi-toothed cutting tool to remove material from a stationary workpiece, ideal for creating complex shapes, slots, and surfaces. Both machining processes are fundamental in manufacturing, offering distinct advantages depending on the shape and precision requirements of the component.

Key Differences Between Lathe and Milling Machines

Lathe operation involves rotating the workpiece against a stationary cutting tool to shape cylindrical components, while milling operation uses a rotating cutting tool to remove material from a stationary workpiece for complex shapes. Key differences include the axis of rotation: lathes rotate the workpiece, and milling machines rotate the tool. Milling operations accommodate multi-axis movement, enabling the creation of intricate geometries, whereas lathes primarily perform turning tasks for symmetrical objects.

Core Functions of Lathe Operations

Lathe operations primarily focus on rotating the workpiece to perform cutting, drilling, sanding, and deforming tasks, enabling precise cylindrical shaping and threading. The core functions include turning, facing, grooving, and tapering, which remove material symmetrically around the axis of rotation. Compared to milling operations that move the cutting tool laterally over a stationary workpiece, lathe machining offers superior accuracy for round components like shafts, bushings, and pulleys.

Core Functions of Milling Operations

Milling operations primarily focus on removing material through rotary cutters, enabling complex shaping, slotting, and surface contouring with high precision. Core functions include facing, drilling, slotting, and cutting gears, making milling versatile for creating intricate parts from metal or other materials. These capabilities distinguish milling from lathe operations, which predominantly involve turning to shape cylindrical objects.

Types of Materials Machined by Lathe vs Milling

Lathes primarily machine cylindrical or round materials such as metals, plastics, and wood, efficiently handling shafts, rods, and tubes by rotating the workpiece against a cutting tool. Milling operations excel in shaping flat, irregular, or complex surfaces on materials like aluminum, steel, brass, and composites by moving the cutting tool against a stationary workpiece. The choice between lathe and milling depends on material form and desired geometry, with lathes suited for symmetrical parts and mills for intricate surface features.

Precision and Surface Finish: Lathe vs Milling

Lathe operations excel in producing cylindrical parts with high precision and superior surface finish, especially for rotational symmetrical components, due to consistent tool contact and controlled cutting speeds. Milling operations offer versatility for complex shapes but generally exhibit slightly lower surface finish quality and dimensional accuracy compared to lathes, particularly on flat or irregular surfaces. The choice between lathe and milling depends on the required geometric complexity and surface texture tolerances of the final product.

Tooling Requirements for Lathe and Milling Operations

Lathe operation tooling primarily requires a single-point cutting tool designed for turning, facing, threading, and grooving, often mounted on a tool post with precise adjustability. Milling operation tooling demands multi-point cutting tools such as end mills, face mills, and drill bits, compatible with milling machines that allow complex machining in multiple axes. Both operations require tool materials like carbide or high-speed steel, but milling tools must withstand higher lateral forces and heat due to the nature of multi-directional cutting.

Typical Industrial Applications: Lathe vs Milling

Lathe machines excel in producing cylindrical parts such as shafts, bushings, and pulleys, widely used in automotive and aerospace industries due to their precision in turning operations. Milling machines are preferred for creating complex shapes, slots, and holes in materials, making them essential in manufacturing engine components, molds, and dies in various industrial sectors. Both machining processes are integral to metalworking, but lathes dominate in rotational geometry while milling addresses multi-axis cutting for diverse applications.

Cost, Efficiency, and Production Output Comparison

Lathe operations typically offer lower initial setup costs and faster cycle times for cylindrical parts, making them more cost-effective for small to medium production runs. Milling operations, though generally more expensive due to complex tooling and longer setup, provide greater versatility and precision, resulting in higher efficiency and production output for intricate, multi-axis components. When evaluating manufacturing needs, cost-effectiveness favors lathe for simpler tasks, while milling is optimal for complex geometries requiring higher throughput and tighter tolerances.

Choosing the Right Operation for Your Project

Selecting the appropriate machine operation depends on the project's material shape and required precision. Lathe operations excel in producing symmetrical cylindrical parts through rotation and cutting, ideal for shafts, bolts, and pulleys. Milling operations offer versatility in shaping complex surfaces with multi-axis movement, making them suitable for detailed components like gears and intricate molds.

Lathe Operation vs Milling Operation Infographic

productdif.com

productdif.com