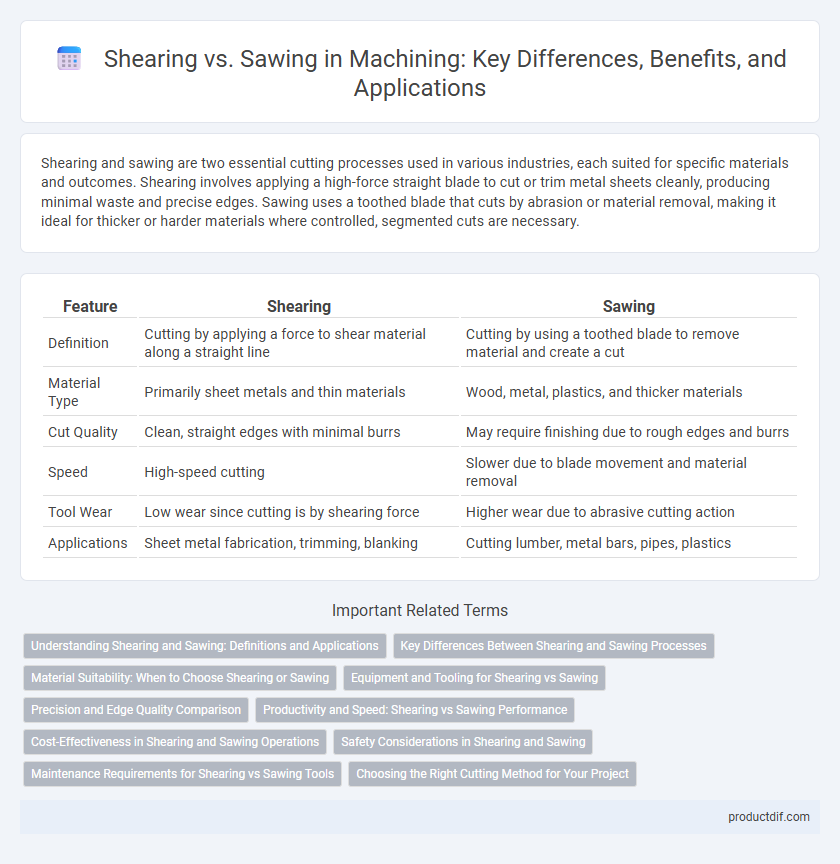

Shearing and sawing are two essential cutting processes used in various industries, each suited for specific materials and outcomes. Shearing involves applying a high-force straight blade to cut or trim metal sheets cleanly, producing minimal waste and precise edges. Sawing uses a toothed blade that cuts by abrasion or material removal, making it ideal for thicker or harder materials where controlled, segmented cuts are necessary.

Table of Comparison

| Feature | Shearing | Sawing |

|---|---|---|

| Definition | Cutting by applying a force to shear material along a straight line | Cutting by using a toothed blade to remove material and create a cut |

| Material Type | Primarily sheet metals and thin materials | Wood, metal, plastics, and thicker materials |

| Cut Quality | Clean, straight edges with minimal burrs | May require finishing due to rough edges and burrs |

| Speed | High-speed cutting | Slower due to blade movement and material removal |

| Tool Wear | Low wear since cutting is by shearing force | Higher wear due to abrasive cutting action |

| Applications | Sheet metal fabrication, trimming, blanking | Cutting lumber, metal bars, pipes, plastics |

Understanding Shearing and Sawing: Definitions and Applications

Shearing involves cutting material by applying a high force through a blade to cause deformation and separation, commonly used in metalworking for shaping sheets and plates. Sawing is a mechanical process that removes material by abrasive or toothed blades, ideal for cutting wood, metal, or plastics into precise shapes or sizes. Both methods serve distinct industrial applications, with shearing excelling in clean, straight cuts on sheet materials and sawing enabling complex or curved cuts with precision.

Key Differences Between Shearing and Sawing Processes

Shearing involves cutting materials by applying a linear force that causes the material to deform and fracture along a straight line, making it ideal for sheet metal and thin materials. Sawing uses a toothed blade to remove material by abrasive action or cutting, suitable for thicker materials and producing more intricate shapes. Shearing provides faster, clean cuts with minimal material loss, while sawing offers greater precision and versatility for diverse material types and thicknesses.

Material Suitability: When to Choose Shearing or Sawing

Shearing is ideal for cutting sheet metal, thin plates, and materials that require precise, straight cuts without generating heat or deformation. Sawing is better suited for thicker, harder materials such as wood, metal bars, and plastics where intricate shapes or curves and deeper cuts are necessary. Selecting between shearing and sawing depends on material thickness, hardness, and the desired cut accuracy.

Equipment and Tooling for Shearing vs Sawing

Shearing equipment uses high-force blades to cut metal sheets along a straight line, producing clean edges with minimal material deformation and no chips. Sawing tools employ toothed blades or abrasive discs to remove material through a cutting action, suitable for thicker or irregular shapes but generating heat and waste chips. Choosing between shearing and sawing depends on the required precision, material thickness, and the nature of the cut, with shearing offering faster, cost-effective straight cuts and sawing providing versatility for complex geometries.

Precision and Edge Quality Comparison

Shearing provides high precision with clean, burr-free edges ideal for thin materials, while sawing offers versatility across various thicknesses but may produce rougher edges requiring secondary finishing. The blade design and cutting method in shearing ensure minimal material distortion, enhancing edge quality compared to the abrasive action of sawing. Choosing shearing over sawing depends on the need for tight tolerances and superior surface finish in metal fabrication.

Productivity and Speed: Shearing vs Sawing Performance

Shearing offers higher productivity and speed by quickly cutting large sheet metal with minimal setup time, making it ideal for straight cuts in industrial applications. Sawing, while generally slower, excels in precision cutting of thick or irregular materials, often requiring additional finishing work that impacts overall throughput. Choosing shearing over sawing improves cycle times and operational efficiency when working with uniform, thin metal sheets in mass production.

Cost-Effectiveness in Shearing and Sawing Operations

Shearing operations typically offer lower operational costs due to faster processing times and minimal tool wear compared to sawing, which often requires frequent blade replacements and higher energy consumption. Sawing is more cost-effective for complex or irregular cuts where precision outweighs throughput, despite higher material waste and slower machining speeds. Evaluating material type, production volume, and cut complexity is essential for selecting the most cost-efficient method between shearing and sawing.

Safety Considerations in Shearing and Sawing

Proper safety measures in shearing involve using guards on blades, ensuring operator training to prevent hand injuries, and implementing emergency stop mechanisms to reduce accident risks. In sawing, maintaining sharp blades, securing materials firmly, and wearing personal protective equipment like goggles and gloves are essential to avoid cuts, kickbacks, and flying debris. Both processes require regular equipment inspections and adherence to safety protocols to minimize workplace hazards and ensure operator protection.

Maintenance Requirements for Shearing vs Sawing Tools

Shearing tools require regular blade sharpening and alignment checks to maintain clean, precise cuts and prevent material deformation. Sawing tools demand frequent blade inspections for tooth wear and tension adjustments to ensure efficient cutting performance and extend blade life. Proper lubrication and timely replacement of worn parts are essential in both methods to minimize downtime and enhance tool longevity.

Choosing the Right Cutting Method for Your Project

Selecting between shearing and sawing depends on the material type, thickness, and desired cut precision; shearing offers clean, straight cuts ideal for sheet metals, while sawing provides versatile cutting options for wood, metal, and plastics with intricate shapes. Consider factors such as edge finish, cutting speed, and material waste, as shearing minimizes burrs and saw cuts may require secondary finishing. For projects demanding high precision and minimal distortion, laser or waterjet cutting could complement or replace traditional shearing and sawing methods.

Shearing vs Sawing Infographic

productdif.com

productdif.com