Cutting tools remove material through shear deformation, creating precise shapes with sharp edges ideal for milling or turning. Grinding tools use abrasive particles to wear down surfaces, achieving finer finishes and tighter tolerances on harder materials. Selecting the appropriate tool depends on the desired surface quality, material hardness, and machining accuracy.

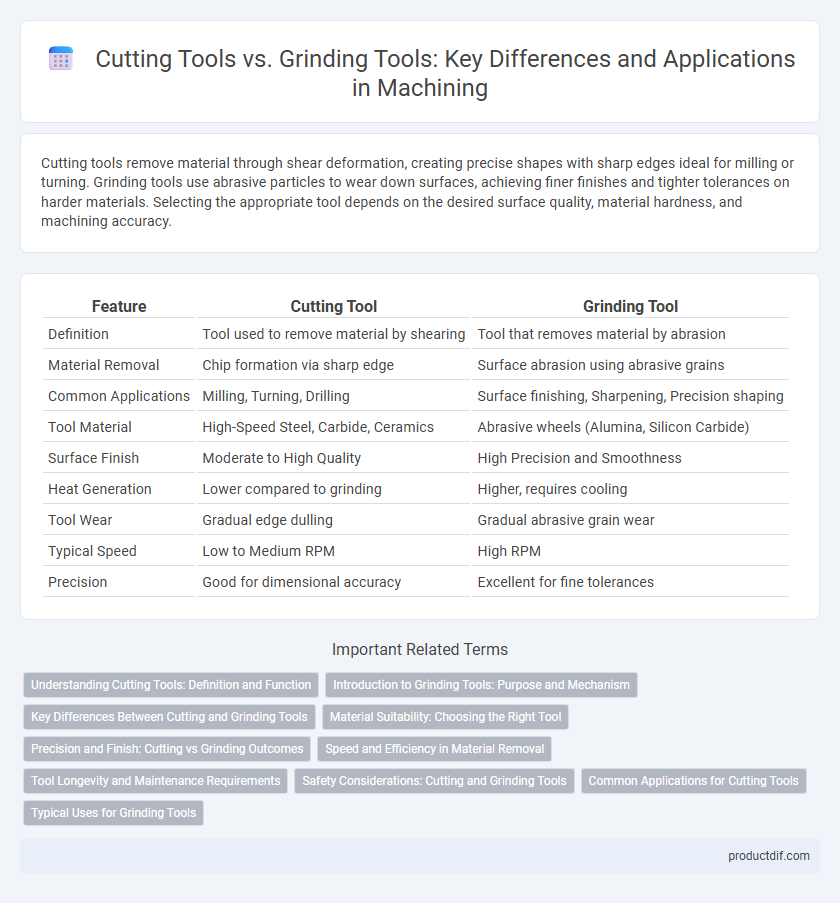

Table of Comparison

| Feature | Cutting Tool | Grinding Tool |

|---|---|---|

| Definition | Tool used to remove material by shearing | Tool that removes material by abrasion |

| Material Removal | Chip formation via sharp edge | Surface abrasion using abrasive grains |

| Common Applications | Milling, Turning, Drilling | Surface finishing, Sharpening, Precision shaping |

| Tool Material | High-Speed Steel, Carbide, Ceramics | Abrasive wheels (Alumina, Silicon Carbide) |

| Surface Finish | Moderate to High Quality | High Precision and Smoothness |

| Heat Generation | Lower compared to grinding | Higher, requires cooling |

| Tool Wear | Gradual edge dulling | Gradual abrasive grain wear |

| Typical Speed | Low to Medium RPM | High RPM |

| Precision | Good for dimensional accuracy | Excellent for fine tolerances |

Understanding Cutting Tools: Definition and Function

Cutting tools are precision instruments designed to remove material from a workpiece by shear deformation, typically through processes like turning, milling, or drilling, enabling the shaping and sizing of components. Unlike grinding tools that use abrasive action to finish surfaces, cutting tools feature sharp edges that enable controlled material removal at higher rates and with specific geometries. Their function centers on producing accurate dimensions and surface finishes while maintaining tool durability under varying operational conditions.

Introduction to Grinding Tools: Purpose and Mechanism

Grinding tools are designed to remove material with high precision using abrasive particles that shear off small fragments from a workpiece. These tools operate through rotational motion, where a grinding wheel or disc grinds surfaces to achieve smooth finishes, tight tolerances, and specific shapes. Commonly used in metalworking and manufacturing, grinding tools excel at refining edges and preparing surfaces for further machining.

Key Differences Between Cutting and Grinding Tools

Cutting tools remove material by shear deformation using a sharp edge, ideal for shaping and sizing workpieces with precision. Grinding tools utilize abrasive particles to wear away material through friction, enabling surface finishing and achieving fine tolerances. Key differences include material removal mechanisms, surface finish quality, tool geometry, and application scope in manufacturing processes.

Material Suitability: Choosing the Right Tool

Cutting tools are ideal for materials like metals, plastics, and wood, offering precise shaping and removal through shear deformation. Grinding tools excel in finishing hard materials such as hardened steels and ceramics, providing superior surface smoothness by abrasive action. Selecting the right tool depends on the material hardness, desired surface finish, and tolerance requirements in machining operations.

Precision and Finish: Cutting vs Grinding Outcomes

Cutting tools deliver precise dimensional accuracy with sharp edges ideal for shaping materials through shear deformation, resulting in smooth surfaces and consistent tolerances. Grinding tools excel in achieving superior surface finishes and tight geometric tolerances by removing fine material layers via abrasive particles, essential for components requiring high precision. The choice between cutting and grinding tools depends on the desired finish quality and dimensional accuracy, with grinding favored for ultra-fine surface refinement and cutting preferred for rough shaping with moderate precision.

Speed and Efficiency in Material Removal

Cutting tools typically offer higher material removal rates due to their ability to shear material quickly with sharp edges, making them more efficient for shaping and sizing operations. Grinding tools operate at higher surface speeds but remove less material per pass through abrasive action, providing finer finishes and tighter tolerances. The choice between cutting and grinding tools depends on balancing speed of removal with precision requirements in manufacturing processes.

Tool Longevity and Maintenance Requirements

Cutting tools typically offer longer tool longevity when used within their optimal material and speed ranges, as they are designed for efficient material removal with minimal wear. Grinding tools require more frequent maintenance due to the abrasive nature of the process, which causes faster wear of the grinding wheel and demands regular dressing and balancing. Proper selection between cutting and grinding tools depends on balancing tool life with maintenance schedules to optimize machining efficiency and reduce downtime.

Safety Considerations: Cutting and Grinding Tools

Cutting tools require proper handling to prevent sharp edge injuries and should be used with appropriate gloves and eye protection. Grinding tools generate sparks and debris, necessitating the use of safety shields, respirators, and face guards to protect against flying particles and inhalation hazards. Both tool types demand routine inspection and maintenance to ensure operational safety and prevent accidents in industrial or workshop environments.

Common Applications for Cutting Tools

Cutting tools are primarily used in machining processes such as turning, milling, drilling, and sawing to precisely remove material from a workpiece. These tools excel in operations requiring high accuracy and complex geometries, commonly found in metalworking, woodworking, and plastic manufacturing industries. Cutting tools are essential for producing components like engine parts, gears, and intricate molds where sharp edges and fine finishes are critical.

Typical Uses for Grinding Tools

Grinding tools are primarily used for precision finishing and surface smoothing of metal, ceramics, and composites. They efficiently remove small amounts of material to achieve tight tolerances and fine surface finishes in manufacturing processes. Typical applications include sharpening cutting tools, shaping hard materials, and preparing surfaces for further processing.

Cutting Tool vs Grinding Tool Infographic

productdif.com

productdif.com