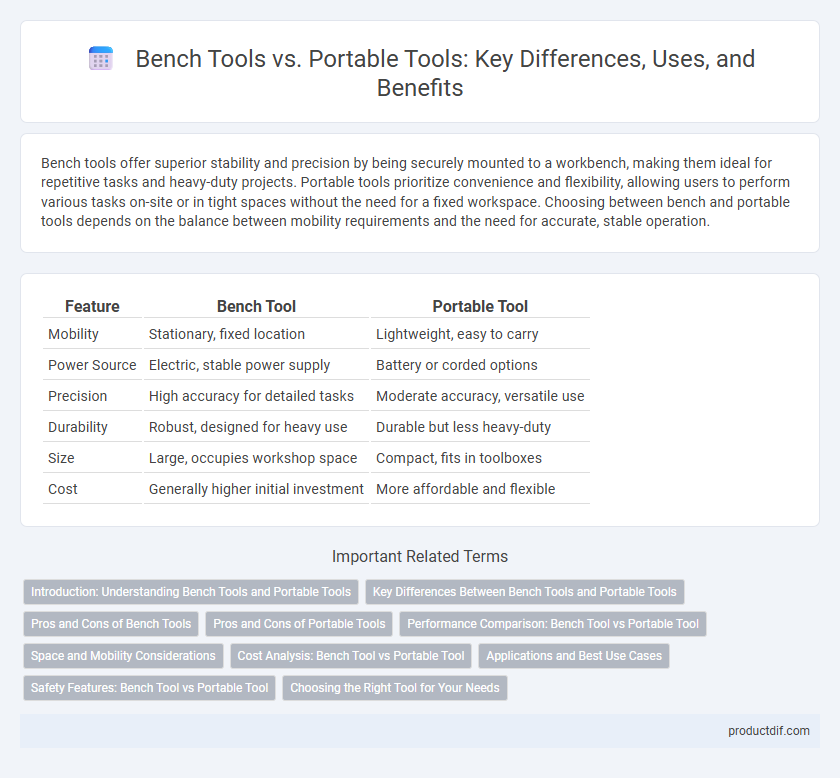

Bench tools offer superior stability and precision by being securely mounted to a workbench, making them ideal for repetitive tasks and heavy-duty projects. Portable tools prioritize convenience and flexibility, allowing users to perform various tasks on-site or in tight spaces without the need for a fixed workspace. Choosing between bench and portable tools depends on the balance between mobility requirements and the need for accurate, stable operation.

Table of Comparison

| Feature | Bench Tool | Portable Tool |

|---|---|---|

| Mobility | Stationary, fixed location | Lightweight, easy to carry |

| Power Source | Electric, stable power supply | Battery or corded options |

| Precision | High accuracy for detailed tasks | Moderate accuracy, versatile use |

| Durability | Robust, designed for heavy use | Durable but less heavy-duty |

| Size | Large, occupies workshop space | Compact, fits in toolboxes |

| Cost | Generally higher initial investment | More affordable and flexible |

Introduction: Understanding Bench Tools and Portable Tools

Bench tools are stationary devices designed for heavy-duty tasks, offering stability and precision in workshops and industrial settings. Portable tools provide flexibility and convenience, allowing users to perform varied tasks on-site or in different locations with ease. Choosing between bench and portable tools depends on the application requirements, workspace constraints, and the need for mobility.

Key Differences Between Bench Tools and Portable Tools

Bench tools offer high stability and precision for heavy-duty tasks, typically fixed in one location, while portable tools provide flexibility and ease of transport for on-site or remote work. Bench tools generally feature larger motors and robust construction, delivering superior power compared to the lightweight, compact design of portable tools. The choice between bench and portable tools depends on the job's mobility requirements and the need for accuracy or power.

Pros and Cons of Bench Tools

Bench tools provide high stability and precision due to their fixed placement, making them ideal for heavy-duty and repetitive tasks in workshops. Their larger size and weight limit portability and require dedicated space, which can be a disadvantage for users with limited workspace. Maintenance and setup are generally easier with bench tools because of their stationary nature and robust construction.

Pros and Cons of Portable Tools

Portable tools offer unmatched flexibility by allowing users to perform tasks in various locations without the need for a fixed workspace. Their lightweight design enhances mobility and ease of use in tight or remote spaces, though they may compromise on power and durability compared to bench tools. Battery life and capacity limitations can also affect efficiency during extended projects, making them less ideal for heavy-duty, continuous work.

Performance Comparison: Bench Tool vs Portable Tool

Bench tools typically deliver higher performance due to their robust motors and stable construction, enabling extended use and handling tougher materials with greater precision. Portable tools offer convenience and flexibility for on-site tasks but may sacrifice power and durability compared to bench-mounted counterparts. Evaluating project requirements helps determine whether the enhanced performance of a bench tool outweighs the portability benefits of handheld options.

Space and Mobility Considerations

Bench tools typically require a fixed workspace, making them ideal for detailed tasks but limiting mobility and space efficiency. Portable tools offer greater flexibility by enabling work in various locations while occupying minimal storage space, enhancing convenience for on-the-go projects. Choosing between bench and portable tools depends largely on available workspace and the need for transportability in specific applications.

Cost Analysis: Bench Tool vs Portable Tool

Bench tools typically involve a higher initial investment due to their robust construction and stationary setup, making them cost-effective for long-term, high-volume tasks. Portable tools offer lower upfront costs and flexibility, ideal for on-site jobs, but may incur additional expenses from maintenance and reduced durability over time. Evaluating total cost of ownership requires considering usage frequency, task complexity, and mobility needs to determine the most economical choice.

Applications and Best Use Cases

Bench tools excel in precision and stability, ideal for heavy-duty tasks like metalworking, woodworking, and detailed fabrication in workshops. Portable tools offer unmatched flexibility, perfect for on-site repairs, construction projects, and tasks requiring mobility or limited workspace. Choosing between bench and portable tools depends on the specific application, with bench tools favored for high-accuracy, repetitive operations and portable tools suited for convenience and versatility in varied environments.

Safety Features: Bench Tool vs Portable Tool

Bench tools often incorporate fixed safety guards and emergency stop buttons, reducing the risk of accidents during precise, repetitive tasks. Portable tools prioritize lightweight design and include features like automatic shut-off and insulated handles to protect users in diverse environments. Both tool types enhance safety, but bench tools excel in stability while portable tools offer mobility and user protection on the move.

Choosing the Right Tool for Your Needs

Bench tools provide stability and precision ideal for heavy-duty tasks and repetitive work, making them essential for professional workshops. Portable tools offer versatility and convenience, perfect for on-site jobs or DIY projects that require mobility and quick setup. Assessing your specific project requirements, workspace limitations, and frequency of use ensures selecting the right tool type enhances productivity and efficiency.

Bench Tool vs Portable Tool Infographic

productdif.com

productdif.com