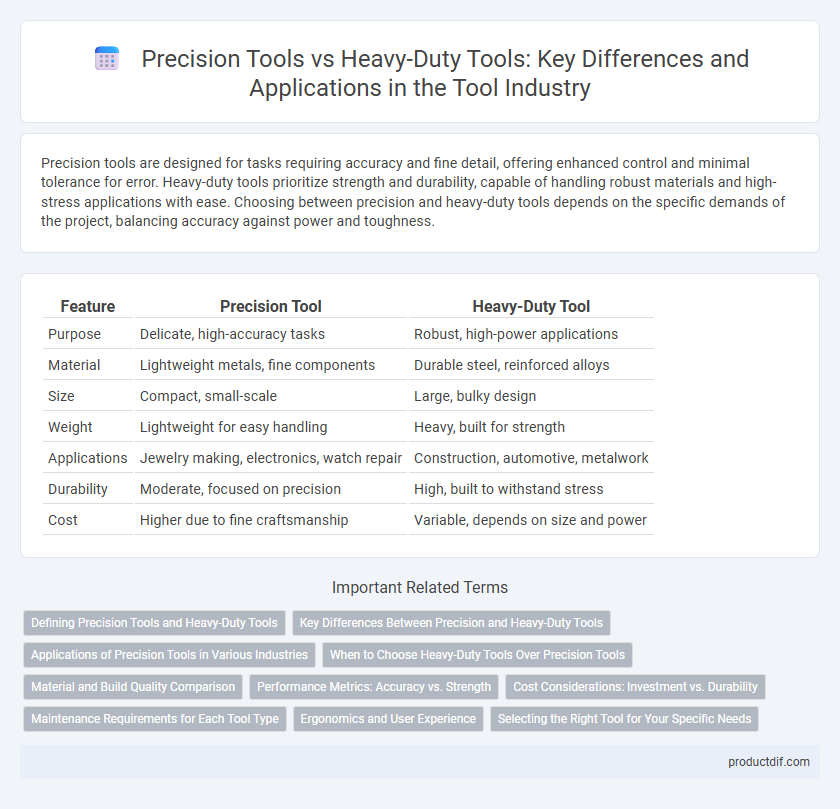

Precision tools are designed for tasks requiring accuracy and fine detail, offering enhanced control and minimal tolerance for error. Heavy-duty tools prioritize strength and durability, capable of handling robust materials and high-stress applications with ease. Choosing between precision and heavy-duty tools depends on the specific demands of the project, balancing accuracy against power and toughness.

Table of Comparison

| Feature | Precision Tool | Heavy-Duty Tool |

|---|---|---|

| Purpose | Delicate, high-accuracy tasks | Robust, high-power applications |

| Material | Lightweight metals, fine components | Durable steel, reinforced alloys |

| Size | Compact, small-scale | Large, bulky design |

| Weight | Lightweight for easy handling | Heavy, built for strength |

| Applications | Jewelry making, electronics, watch repair | Construction, automotive, metalwork |

| Durability | Moderate, focused on precision | High, built to withstand stress |

| Cost | Higher due to fine craftsmanship | Variable, depends on size and power |

Defining Precision Tools and Heavy-Duty Tools

Precision tools are specialized instruments designed for tasks requiring high accuracy and fine detail, such as watchmaking or electronics repair. Heavy-duty tools are robust, built to withstand strenuous use and handle large-scale construction or industrial projects. Each tool type addresses specific needs, with precision tools emphasizing meticulous craftsmanship and heavy-duty tools providing exceptional strength and durability.

Key Differences Between Precision and Heavy-Duty Tools

Precision tools offer high accuracy and fine control, ideal for delicate tasks requiring exact measurements and minimal tolerance, such as watchmaking or electronics assembly. Heavy-duty tools provide robust construction and enhanced power for demanding applications like construction, automotive repair, or metal fabrication, where durability and force are essential. Key differences include the scale of work, with precision tools emphasizing meticulous detail and heavy-duty tools prioritizing strength and endurance.

Applications of Precision Tools in Various Industries

Precision tools are essential in industries such as electronics, aerospace, and medical device manufacturing where accuracy and fine detail are critical. These tools enable tasks like intricate circuit board assembly, precise component alignment, and microsurgery equipment fabrication, ensuring high-quality outcomes. They outperform heavy-duty tools in applications demanding exact measurements and delicate handling.

When to Choose Heavy-Duty Tools Over Precision Tools

Heavy-duty tools are ideal when working on large-scale projects requiring maximum power and durability, such as construction or metalworking tasks. They excel in handling tough materials, providing long-lasting performance under rigorous conditions where precision tools may fail. Choosing heavy-duty tools ensures efficiency and strength for demanding applications beyond the fine accuracy offered by precision counterparts.

Material and Build Quality Comparison

Precision tools are crafted from high-grade steel alloys and feature finely machined components to ensure exact measurements and delicate handling, emphasizing durability in smaller, intricate parts. Heavy-duty tools utilize hardened steel or cast iron with reinforced handles and robust construction designed to withstand significant physical stress and prolonged use in demanding environments. Material selection and build quality define the fundamental difference, where precision tools prioritize exactness and fine tolerances, while heavy-duty tools emphasize strength and resilience.

Performance Metrics: Accuracy vs. Strength

Precision tools excel in accuracy, offering fine tolerances often within micrometers, ideal for delicate tasks requiring exact measurements. Heavy-duty tools prioritize strength and durability, delivering high torque and resistance to wear for demanding industrial applications. Performance metrics for precision tools emphasize repeatability and minimal error margins, while heavy-duty tools focus on power output and longevity under continuous stress.

Cost Considerations: Investment vs. Durability

Precision tools often require a higher initial investment due to their specialized design and accuracy, making them cost-effective for tasks demanding fine detail and minimal error margins. Heavy-duty tools typically have lower upfront costs but incur long-term expenses through more frequent repairs or replacements, given their exposure to intense wear and stress. Evaluating cost considerations involves balancing the precision tool's upfront price with its longevity and accuracy against the heavy-duty tool's durability and maintenance needs over time.

Maintenance Requirements for Each Tool Type

Precision tools demand meticulous maintenance, including regular calibration, cleaning, and lubrication to maintain accuracy and functionality. Heavy-duty tools require robust upkeep, such as frequent inspection for wear, tightening of fasteners, and replacement of worn parts to endure tough working conditions. Proper maintenance protocols extend the lifespan and performance reliability of both precision and heavy-duty tools in their respective applications.

Ergonomics and User Experience

Precision tools prioritize ergonomic design to enhance user comfort and control during tasks that demand accuracy, reducing hand fatigue with lightweight materials and balanced grips. Heavy-duty tools focus on durability and power, often incorporating robust handles and vibration-dampening features to improve user experience during prolonged, intense use. Both tool types aim to optimize ergonomics, but precision tools emphasize finesse while heavy-duty tools cater to sustained force and impact resistance.

Selecting the Right Tool for Your Specific Needs

Selecting the right tool depends on the task requirements, with precision tools ideal for detailed, delicate work requiring high accuracy and fine control. Heavy-duty tools are designed for robust applications, offering durability and power to handle tough materials and extended use. Understanding the specific demands of your project ensures optimal performance, efficiency, and tool longevity by matching precision tools for intricate tasks and heavy-duty tools for rigorous workloads.

Precision Tool vs Heavy-Duty Tool Infographic

productdif.com

productdif.com