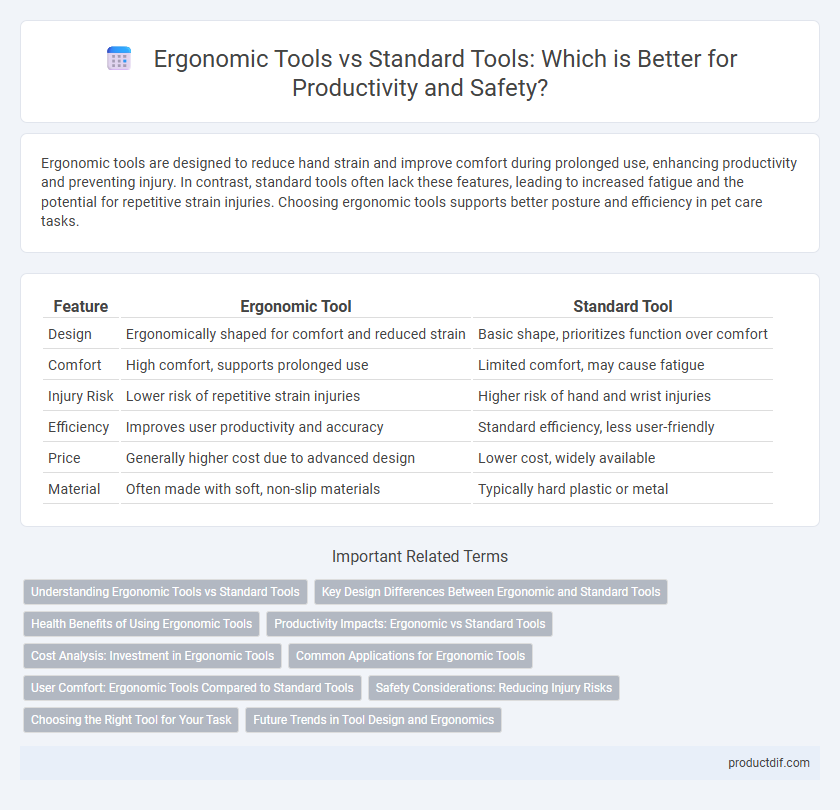

Ergonomic tools are designed to reduce hand strain and improve comfort during prolonged use, enhancing productivity and preventing injury. In contrast, standard tools often lack these features, leading to increased fatigue and the potential for repetitive strain injuries. Choosing ergonomic tools supports better posture and efficiency in pet care tasks.

Table of Comparison

| Feature | Ergonomic Tool | Standard Tool |

|---|---|---|

| Design | Ergonomically shaped for comfort and reduced strain | Basic shape, prioritizes function over comfort |

| Comfort | High comfort, supports prolonged use | Limited comfort, may cause fatigue |

| Injury Risk | Lower risk of repetitive strain injuries | Higher risk of hand and wrist injuries |

| Efficiency | Improves user productivity and accuracy | Standard efficiency, less user-friendly |

| Price | Generally higher cost due to advanced design | Lower cost, widely available |

| Material | Often made with soft, non-slip materials | Typically hard plastic or metal |

Understanding Ergonomic Tools vs Standard Tools

Ergonomic tools are specifically designed to reduce user fatigue and prevent musculoskeletal injuries by optimizing the tool's shape, weight, and grip, whereas standard tools often lack these human-centered design features. Studies show ergonomic tools can improve efficiency and comfort during repetitive or extended tasks, leading to fewer work-related injuries and higher productivity. The integration of ergonomic principles in tool design emphasizes user safety and long-term health benefits over traditional tool functionality.

Key Design Differences Between Ergonomic and Standard Tools

Ergonomic tools feature contoured handles, non-slip grips, and balanced weight distribution designed to reduce muscle strain and enhance comfort during extended use. Standard tools typically have straight, rigid handles and heavier weights, which can lead to increased fatigue and repetitive strain injuries. The key design differences emphasize user comfort and efficiency in ergonomic tools versus basic functionality in standard tools.

Health Benefits of Using Ergonomic Tools

Ergonomic tools reduce strain on muscles and joints, minimizing the risk of repetitive strain injuries (RSIs) such as carpal tunnel syndrome and tendinitis. These tools promote proper hand, wrist, and arm alignment, which enhances comfort and decreases fatigue during prolonged use. Studies show that workers using ergonomic tools experience fewer musculoskeletal disorders and improved overall productivity compared to those using standard tools.

Productivity Impacts: Ergonomic vs Standard Tools

Ergonomic tools significantly enhance productivity by reducing user fatigue and minimizing the risk of repetitive strain injuries compared to standard tools. Studies show workers using ergonomic tools experience up to a 25% increase in task efficiency and a 30% decrease in error rates. The improved comfort and precision offered by ergonomic designs lead to higher output quality and sustained performance over longer periods.

Cost Analysis: Investment in Ergonomic Tools

Investing in ergonomic tools often involves higher upfront costs compared to standard tools, but these expenses are offset by reduced worker fatigue and lower injury rates, leading to decreased compensation claims and absenteeism. Studies indicate that ergonomic tool investments can result in a return on investment (ROI) of up to 150% within the first year due to increased productivity and worker efficiency. Companies prioritizing ergonomic tools benefit from long-term cost savings through enhanced employee well-being and sustained operational performance.

Common Applications for Ergonomic Tools

Ergonomic tools are commonly used in industries requiring repetitive motion tasks, such as assembly lines, automotive manufacturing, and woodworking, to reduce strain and prevent musculoskeletal disorders. These tools feature specially designed handles and grips that enhance comfort and improve efficiency during prolonged use. Their applications also extend to healthcare and gardening, where precision and user comfort significantly impact productivity and safety.

User Comfort: Ergonomic Tools Compared to Standard Tools

Ergonomic tools significantly enhance user comfort by reducing strain and improving grip compared to standard tools, which often cause fatigue during prolonged use. Features such as contoured handles, cushioned grips, and balanced weight distribution minimize wrist and hand stress. These design improvements contribute to increased productivity and reduced risk of repetitive stress injuries for users.

Safety Considerations: Reducing Injury Risks

Ergonomic tools are specifically designed to minimize strain on muscles and joints, significantly reducing the risk of repetitive strain injuries and musculoskeletal disorders compared to standard tools. Features such as cushioned grips, adjustable handles, and balanced weight distribution enhance safety by promoting natural hand positioning and reducing fatigue. Using ergonomic tools in the workplace can lead to fewer accidents and long-term injury risks, improving overall worker health and productivity.

Choosing the Right Tool for Your Task

Ergonomic tools reduce strain and increase comfort by adapting to natural hand positions, making them ideal for prolonged or repetitive tasks. Standard tools may be less expensive but can lead to fatigue and injury if used extensively without proper support. Selecting the right tool requires evaluating task duration, frequency, and user comfort to enhance productivity and prevent musculoskeletal disorders.

Future Trends in Tool Design and Ergonomics

Future trends in tool design emphasize ergonomic innovation, prioritizing user comfort, reducing fatigue, and preventing injury through improved grip and weight distribution. Advanced materials, such as lightweight composites and adaptive handles, are increasingly integrated into ergonomic tools to enhance durability and ease of use compared to standard tools. Smart technology, including sensors and digital feedback systems, is also shaping the future of tool ergonomics by providing real-time data to optimize tool performance and user safety.

Ergonomic Tool vs Standard Tool Infographic

productdif.com

productdif.com