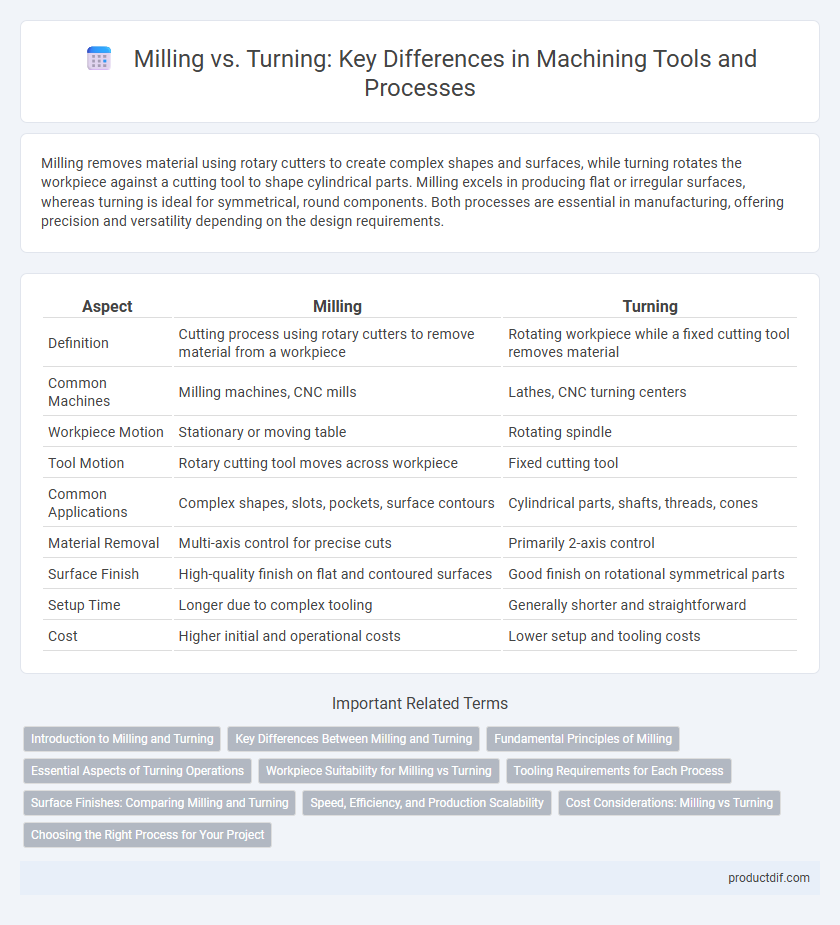

Milling removes material using rotary cutters to create complex shapes and surfaces, while turning rotates the workpiece against a cutting tool to shape cylindrical parts. Milling excels in producing flat or irregular surfaces, whereas turning is ideal for symmetrical, round components. Both processes are essential in manufacturing, offering precision and versatility depending on the design requirements.

Table of Comparison

| Aspect | Milling | Turning |

|---|---|---|

| Definition | Cutting process using rotary cutters to remove material from a workpiece | Rotating workpiece while a fixed cutting tool removes material |

| Common Machines | Milling machines, CNC mills | Lathes, CNC turning centers |

| Workpiece Motion | Stationary or moving table | Rotating spindle |

| Tool Motion | Rotary cutting tool moves across workpiece | Fixed cutting tool |

| Common Applications | Complex shapes, slots, pockets, surface contours | Cylindrical parts, shafts, threads, cones |

| Material Removal | Multi-axis control for precise cuts | Primarily 2-axis control |

| Surface Finish | High-quality finish on flat and contoured surfaces | Good finish on rotational symmetrical parts |

| Setup Time | Longer due to complex tooling | Generally shorter and straightforward |

| Cost | Higher initial and operational costs | Lower setup and tooling costs |

Introduction to Milling and Turning

Milling involves removing material from a workpiece using rotary cutters, enabling precise shaping and surface finishing across various metals and plastics. Turning, performed on a lathe, rotates the workpiece while a cutting tool shapes its exterior, commonly used for cylindrical parts such as shafts and bolts. Both processes are fundamental in manufacturing for creating complex geometries and ensuring tight tolerances in mechanical components.

Key Differences Between Milling and Turning

Milling involves the removal of material using rotary cutters to shape a workpiece, while turning rotates the workpiece against a stationary cutting tool. Milling machines typically handle complex shapes and multiple axes, whereas turning centers focus on creating cylindrical parts through controlled rotation. The key differences lie in their kinematic motions, tool types, and typical applications within manufacturing processes.

Fundamental Principles of Milling

Milling involves the use of rotary cutters to remove material from a workpiece by advancing the cutter into the workpiece in a controlled manner, enabling precise shaping and surface finishing. The fundamental principle of milling is the relative motion between the rotating cutter and the stationary workpiece, which generates chips by shear deformation. This process allows for complex geometries and a wide range of material removal rates, making it essential in manufacturing industries for creating detailed parts.

Essential Aspects of Turning Operations

Turning operations primarily involve rotating a workpiece against a cutting tool to remove material and achieve desired shapes, crucial for producing cylindrical components. Key aspects include spindle speed, feed rate, depth of cut, and tool geometry, all of which influence surface finish and dimensional accuracy. The ability to perform facing, threading, and grooving enhances versatility and efficiency in manufacturing processes requiring precision and repeatability.

Workpiece Suitability for Milling vs Turning

Milling machines excel in shaping complex, irregular workpieces with varying contours and surfaces, making them ideal for parts requiring multiple angles and detailed features. Turning is best suited for cylindrical or symmetrical workpieces, such as shafts and rods, where the material is rotated against a cutting tool to achieve precision diameters and smooth finishes. Selecting between milling and turning depends largely on the geometry and surface requirements of the workpiece, with milling favored for multi-axis complexity and turning for round or tapered shapes.

Tooling Requirements for Each Process

Milling requires a variety of cutting tools such as end mills, face mills, and drills, each designed to remove material from different surfaces or features, demanding frequent tool changes for complex geometries. Turning involves single-point cutting tools mounted on a lathe, optimized for cylindrical parts, and typically requires tools with specific angles for roughing or finishing operations. Both processes demand precise tool materials and coatings to withstand wear and maintain dimensional accuracy under distinct cutting conditions.

Surface Finishes: Comparing Milling and Turning

Milling generally produces finer surface finishes due to controlled, multi-directional cutting with rotating cutters, ideal for complex geometries and precision detailing. Turning offers smoother finishes on rotationally symmetric parts by utilizing continuous cutting on a fixed axis, but may exhibit tool marks or chatter on certain materials. Selecting between milling and turning depends on desired surface quality, part geometry, and material characteristics for optimal finishing results.

Speed, Efficiency, and Production Scalability

Milling offers higher precision and versatility at moderate speeds, making it ideal for complex shapes and fine details in small to medium production runs. Turning excels in speed and efficiency for cylindrical parts, often enabling faster cycle times and reduced material waste in high-volume manufacturing. Production scalability favors turning for repetitive, large-scale tasks, while milling remains preferable for flexible, low to medium volume outputs requiring diverse geometries.

Cost Considerations: Milling vs Turning

Cost considerations in milling often involve higher initial investment due to more complex machine setups and tooling requirements, but it offers greater versatility for intricate part production. Turning typically incurs lower costs with simpler tool designs and faster cycle times, making it ideal for high-volume, cylindrical components. Evaluating the specific part geometry and production volume is crucial for optimizing expenses between milling and turning processes.

Choosing the Right Process for Your Project

Milling offers versatility in creating complex shapes and contours by removing material with rotary cutters, ideal for intricate designs and multiple surface finishes. Turning excels at producing cylindrical parts with consistent diameters and smooth surface finishes through rotational motion on a lathe, making it perfect for shafts, bolts, and threaded components. Selecting between milling and turning depends on your project's geometry, precision requirements, and production volume to ensure optimal efficiency and cost-effectiveness.

Milling vs Turning Infographic

productdif.com

productdif.com