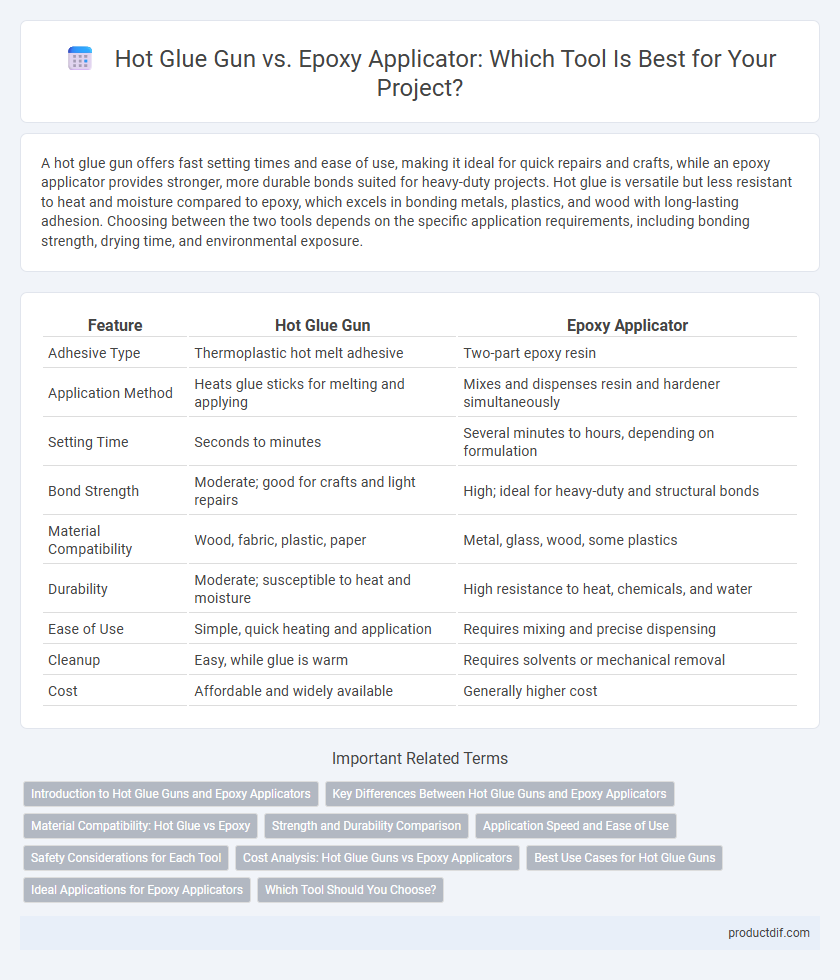

A hot glue gun offers fast setting times and ease of use, making it ideal for quick repairs and crafts, while an epoxy applicator provides stronger, more durable bonds suited for heavy-duty projects. Hot glue is versatile but less resistant to heat and moisture compared to epoxy, which excels in bonding metals, plastics, and wood with long-lasting adhesion. Choosing between the two tools depends on the specific application requirements, including bonding strength, drying time, and environmental exposure.

Table of Comparison

| Feature | Hot Glue Gun | Epoxy Applicator |

|---|---|---|

| Adhesive Type | Thermoplastic hot melt adhesive | Two-part epoxy resin |

| Application Method | Heats glue sticks for melting and applying | Mixes and dispenses resin and hardener simultaneously |

| Setting Time | Seconds to minutes | Several minutes to hours, depending on formulation |

| Bond Strength | Moderate; good for crafts and light repairs | High; ideal for heavy-duty and structural bonds |

| Material Compatibility | Wood, fabric, plastic, paper | Metal, glass, wood, some plastics |

| Durability | Moderate; susceptible to heat and moisture | High resistance to heat, chemicals, and water |

| Ease of Use | Simple, quick heating and application | Requires mixing and precise dispensing |

| Cleanup | Easy, while glue is warm | Requires solvents or mechanical removal |

| Cost | Affordable and widely available | Generally higher cost |

Introduction to Hot Glue Guns and Epoxy Applicators

Hot glue guns and epoxy applicators serve distinct purposes in bonding applications, with hot glue guns utilizing heated thermoplastic adhesive for quick setting and versatility on materials like fabric, wood, and plastic. Epoxy applicators dispense a two-part resin and hardener mixture that cures into a durable, chemical-resistant bond ideal for heavy-duty repairs and industrial uses. Understanding the functional differences in adhesive type, curing process, and application methods helps users select the appropriate tool for their specific project requirements.

Key Differences Between Hot Glue Guns and Epoxy Applicators

Hot glue guns use thermoplastic adhesive that melts quickly and bonds instantly upon cooling, making them ideal for fast, lightweight projects. Epoxy applicators dispense a two-part resin that chemically cures, resulting in a stronger, more durable bond suited for heavy-duty repairs and materials like metal and ceramics. Hot glue is preferred for flexibility and ease of use, while epoxy requires mixing but offers superior strength and resistance to heat and moisture.

Material Compatibility: Hot Glue vs Epoxy

Hot glue guns excel in bonding lightweight materials such as fabric, paper, wood, and some plastics due to their flexible thermoplastic adhesive properties. Epoxy applicators deliver a two-part resin that cures into a rigid, high-strength bond suitable for metals, ceramics, glass, and heavy-duty plastics. The choice between hot glue and epoxy hinges on material compatibility, with hot glue favored for quick, low-stress applications and epoxy preferred for durable, chemical-resistant bonds on diverse substrates.

Strength and Durability Comparison

Hot glue guns provide quick bonding with moderate strength suitable for lightweight materials, while epoxy applicators deliver superior durability and stronger adhesion ideal for heavy-duty repairs and industrial applications. Epoxy resins cure into a rigid, impact-resistant bond that withstands temperature fluctuations and moisture, unlike hot glue which can soften under heat. Selecting epoxy ensures long-lasting structural integrity, whereas hot glue offers convenience for temporary or flexible bonds.

Application Speed and Ease of Use

Hot glue guns offer rapid application with almost instant bonding, making them ideal for quick fixes and crafting projects. Epoxy applicators require mixing and longer curing times but provide stronger, more durable bonds for heavy-duty repairs. Ease of use favors hot glue guns due to their straightforward operation, while epoxy applicators demand precision and patience for accurate application.

Safety Considerations for Each Tool

Hot glue guns operate at high temperatures, posing burn risks that require insulated gloves and careful handling to prevent skin contact with molten adhesive. Epoxy applicators involve chemical components that can cause skin irritation or allergic reactions, necessitating the use of gloves and ventilation to avoid inhaling fumes. Both tools demand proper safety gear, such as eye protection and work in well-ventilated areas, to minimize hazards during application.

Cost Analysis: Hot Glue Guns vs Epoxy Applicators

Hot glue guns generally have a lower upfront cost, typically ranging from $10 to $30, while epoxy applicators can cost between $20 and $50 depending on the brand and features. The price of consumables varies significantly; hot glue sticks are inexpensive and readily available, whereas epoxy resin kits tend to be more expensive but offer stronger bonding properties. Considering long-term use, hot glue guns are cost-effective for quick, low-strength projects, whereas epoxy applicators are more economical for durable repairs despite higher initial expenses.

Best Use Cases for Hot Glue Guns

Hot glue guns excel in quick bonding tasks on porous materials such as fabric, wood, and paper, providing fast drying times ideal for crafting and minor household repairs. Their ease of use and minimal curing time make them perfect for temporary holds and projects requiring immediate handling strength. Hot glue guns are less effective on non-porous surfaces or applications needing high-temperature resistance, where epoxy applicators typically perform better.

Ideal Applications for Epoxy Applicators

Epoxy applicators are ideal for precision bonding and filling small gaps in woodworking, automotive repairs, and jewelry making, where controlled application of thick adhesives is crucial. Their design enables accurate dispensing of two-part epoxy resins, ensuring proper mixing and strong, durable bonds on metal, plastic, and composite materials. These tools excel in applications requiring high strength, chemical resistance, and longevity under stress.

Which Tool Should You Choose?

When deciding between a hot glue gun and an epoxy applicator, consider the project requirements: hot glue guns provide quick bonding with rapid drying ideal for lightweight materials like fabric and plastic, while epoxy applicators deliver strong, durable adhesion suited for metal, wood, and heavy-duty repairs. The temperature sensitivity and curing time differ significantly, with hot glue guns melting adhesive quickly versus epoxy requiring mixing and longer curing. Choose a hot glue gun for speed and ease on minor crafts, or an epoxy applicator when strength and precision in bonding tougher materials are crucial.

Hot Glue Gun vs Epoxy Applicator Infographic

productdif.com

productdif.com