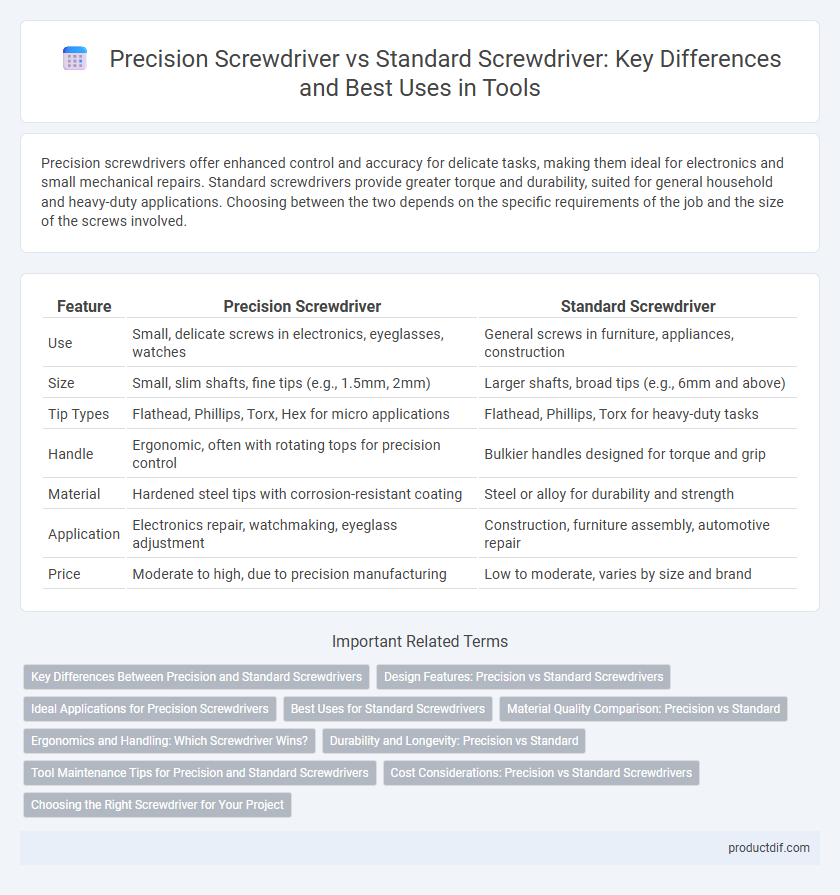

Precision screwdrivers offer enhanced control and accuracy for delicate tasks, making them ideal for electronics and small mechanical repairs. Standard screwdrivers provide greater torque and durability, suited for general household and heavy-duty applications. Choosing between the two depends on the specific requirements of the job and the size of the screws involved.

Table of Comparison

| Feature | Precision Screwdriver | Standard Screwdriver |

|---|---|---|

| Use | Small, delicate screws in electronics, eyeglasses, watches | General screws in furniture, appliances, construction |

| Size | Small, slim shafts, fine tips (e.g., 1.5mm, 2mm) | Larger shafts, broad tips (e.g., 6mm and above) |

| Tip Types | Flathead, Phillips, Torx, Hex for micro applications | Flathead, Phillips, Torx for heavy-duty tasks |

| Handle | Ergonomic, often with rotating tops for precision control | Bulkier handles designed for torque and grip |

| Material | Hardened steel tips with corrosion-resistant coating | Steel or alloy for durability and strength |

| Application | Electronics repair, watchmaking, eyeglass adjustment | Construction, furniture assembly, automotive repair |

| Price | Moderate to high, due to precision manufacturing | Low to moderate, varies by size and brand |

Key Differences Between Precision and Standard Screwdrivers

Precision screwdrivers feature smaller tips and finer shafts designed for delicate tasks such as electronics or eyeglass repairs, offering enhanced control and accuracy. Standard screwdrivers have larger, sturdier tips suited for general construction or automotive work, prioritizing torque and durability over subtlety. Material composition also differs, with precision models often using hardened steel for wear resistance while standard versions emphasize ergonomic handles for robust grip during heavy-duty applications.

Design Features: Precision vs Standard Screwdrivers

Precision screwdrivers feature finely crafted tips designed for delicate tasks, such as electronics repair and small fasteners, offering enhanced control and accuracy. Standard screwdrivers have larger, more robust tips suitable for general-purpose use and handling bigger screws in construction or automotive projects. The ergonomic design of precision screwdrivers often includes non-slip handles and rotating caps to facilitate steady, precise turns, unlike the simpler, heavier grips found on standard screwdrivers.

Ideal Applications for Precision Screwdrivers

Precision screwdrivers are ideal for tasks requiring meticulous control such as electronics repair, watchmaking, and eyeglass adjustments due to their smaller tips and ergonomic design. Unlike standard screwdrivers, they provide the necessary torque and delicacy needed to handle tiny screws without causing damage. These tools excel in environments where space constraints and detailed work demand accuracy above brute force.

Best Uses for Standard Screwdrivers

Standard screwdrivers excel in general household tasks such as assembling furniture, tightening cabinet hinges, and repairing appliances where screws are larger and require more torque. These tools are ideal for tasks involving slotted and Phillips screws in wood, metal, and plastic materials, providing durability and ease of use for everyday maintenance. Their robust design suits jobs that demand leverage and strength rather than the fine control required in delicate electronics or precision work.

Material Quality Comparison: Precision vs Standard

Precision screwdrivers typically use high-grade steel alloys such as S2 tool steel, offering superior hardness and corrosion resistance compared to the softer carbon steel often found in standard screwdrivers. The enhanced material quality in precision screwdrivers ensures greater durability and maintains tip integrity during intricate tasks, which reduces the risk of stripping fasteners. Standard screwdrivers, while adequate for general use, lack the refined metallurgical properties that precision tools require for accuracy and longevity.

Ergonomics and Handling: Which Screwdriver Wins?

Precision screwdrivers are designed with ergonomic handles that provide enhanced grip and control for delicate tasks, reducing hand fatigue during prolonged use. Standard screwdrivers typically feature larger, less contoured handles optimized for high torque applications but may cause discomfort in fine manipulation. Ergonomically, precision screwdrivers win for tasks requiring accuracy and consistent handling, while standard screwdrivers excel in robustness and power.

Durability and Longevity: Precision vs Standard

Precision screwdrivers, crafted with high-grade steel and reinforced tips, offer superior durability and longevity compared to standard screwdrivers. The fine, precisely engineered tips resist wear and maintain shape under repeated use, ensuring consistent performance. While standard screwdrivers may be adequate for general tasks, their broader tips and lower-grade materials often lead to faster deterioration, reducing tool lifespan.

Tool Maintenance Tips for Precision and Standard Screwdrivers

Regular cleaning and proper storage are essential for both precision and standard screwdrivers to maintain their effectiveness and extend tool life. Use a soft cloth to remove debris and apply light oil to prevent rust on metal parts, while ensuring handles are free from grime to maintain grip. Inspect tips regularly for wear or damage to avoid stripping screws and replace or sharpen as needed for optimal performance.

Cost Considerations: Precision vs Standard Screwdrivers

Precision screwdrivers typically have higher manufacturing costs due to their specialized tips and ergonomic designs, resulting in a higher purchase price compared to standard screwdrivers. Standard screwdrivers offer a more economical option for general use, with durable materials and simpler construction. For professionals requiring accuracy in electronics or delicate assemblies, the investment in precision screwdrivers can lead to greater efficiency and reduced damage risk.

Choosing the Right Screwdriver for Your Project

Selecting the right screwdriver depends on the task requirements and screw type, with a precision screwdriver ideal for small, delicate screws in electronics or intricate assemblies. Standard screwdrivers are better suited for general use with larger screws found in woodworking or automotive projects. Matching the screwdriver tip size and type, such as Phillips or flathead, to the screw ensures optimal grip and prevents damage to the screw head or workpiece.

Precision screwdriver vs Standard screwdriver Infographic

productdif.com

productdif.com