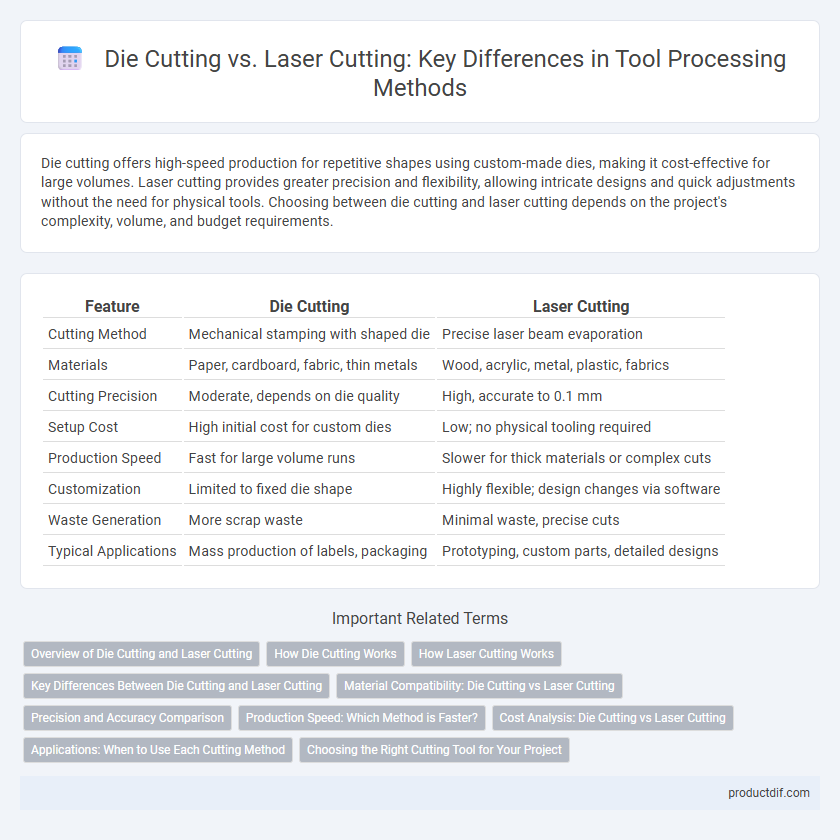

Die cutting offers high-speed production for repetitive shapes using custom-made dies, making it cost-effective for large volumes. Laser cutting provides greater precision and flexibility, allowing intricate designs and quick adjustments without the need for physical tools. Choosing between die cutting and laser cutting depends on the project's complexity, volume, and budget requirements.

Table of Comparison

| Feature | Die Cutting | Laser Cutting |

|---|---|---|

| Cutting Method | Mechanical stamping with shaped die | Precise laser beam evaporation |

| Materials | Paper, cardboard, fabric, thin metals | Wood, acrylic, metal, plastic, fabrics |

| Cutting Precision | Moderate, depends on die quality | High, accurate to 0.1 mm |

| Setup Cost | High initial cost for custom dies | Low; no physical tooling required |

| Production Speed | Fast for large volume runs | Slower for thick materials or complex cuts |

| Customization | Limited to fixed die shape | Highly flexible; design changes via software |

| Waste Generation | More scrap waste | Minimal waste, precise cuts |

| Typical Applications | Mass production of labels, packaging | Prototyping, custom parts, detailed designs |

Overview of Die Cutting and Laser Cutting

Die cutting is a manufacturing process that uses a specialized tool, known as a die, to cut shapes from materials like paper, fabric, or metal by applying mechanical pressure. Laser cutting employs a high-powered laser beam to precisely cut or engrave materials, offering greater flexibility and accuracy for complex designs. Both methods are essential in industries such as packaging, automotive, and textiles, with die cutting favored for high-volume, repetitive shapes and laser cutting preferred for intricate, customized work.

How Die Cutting Works

Die cutting operates by using a custom-shaped metal die to stamp or cut materials such as paper, fabric, or plastic with precision, ensuring consistent shapes and designs. The die presses down on the material, cutting or embossing it based on the applied pressure and the die's sharp edges. This method is highly efficient for mass production, producing uniform results at high speed compared to laser cutting.

How Laser Cutting Works

Laser cutting utilizes a high-powered laser beam directed through optics and computer numerical control (CNC) to precisely cut materials by melting, burning, or vaporizing targeted sections. The process offers superior accuracy and the ability to cut complex shapes on metals, plastics, and other substrates without physical contact, reducing material deformation. This advanced method contrasts with die cutting, which relies on pre-shaped blades to mechanically shear materials.

Key Differences Between Die Cutting and Laser Cutting

Die cutting uses a physical die to stamp shapes from materials, offering high-speed production ideal for large-volume tasks and consistent results with thicker materials. Laser cutting employs a focused laser beam to precisely cut or engrave various materials, enabling intricate designs and customization with minimal setup time. Key differences include speed, material compatibility, design complexity, and initial tooling costs, where die cutting excels in high-volume and repetitive shapes, while laser cutting is preferred for detailed, low-volume, or prototype work.

Material Compatibility: Die Cutting vs Laser Cutting

Die cutting is ideal for mass production with materials like paper, cardstock, leather, and thin plastics, offering consistent shapes but limited flexibility with thicker or harder materials. Laser cutting accommodates a wider range of materials including wood, acrylic, fabric, metal, and rubber, providing precision for intricate designs and the ability to cut through thicker substrates. Material compatibility depends on the project requirements, with die cutting excelling in speed and cost-efficiency for softer, uniform materials while laser cutting excels in versatility and detail for diverse and complex materials.

Precision and Accuracy Comparison

Die cutting offers consistent precision for high-volume production, utilizing custom-made steel dies to achieve exact shapes with tight tolerances. Laser cutting provides superior accuracy for intricate designs and complex patterns, with a focused beam that can reach micron-level precision and minimal material distortion. Choosing between die cutting and laser cutting depends on the required detail, production volume, and material type to optimize precision and accuracy outcomes.

Production Speed: Which Method is Faster?

Die cutting offers faster production speeds for high-volume runs due to its ability to quickly stamp shapes in a single press, making it ideal for mass manufacturing. Laser cutting, while slower on average, provides superior precision and flexibility for complex or custom designs despite requiring more time per piece. Speed efficiency favors die cutting in repetitive, large-scale production scenarios, whereas laser cutting suits lower volume, intricate projects demanding accuracy.

Cost Analysis: Die Cutting vs Laser Cutting

Die cutting generally offers lower per-unit costs for high-volume production due to its efficient repeatability and fixed die expenses, making it cost-effective for mass manufacturing. Laser cutting incurs higher initial equipment and operational costs but excels in flexibility and precision without the need for custom dies, which benefits low-volume or prototype projects. Evaluating cost-effectiveness depends on factors like production volume, material type, and complexity, with die cutting favored for large runs and laser cutting preferred for customization and small batches.

Applications: When to Use Each Cutting Method

Die cutting excels in high-volume production where consistent, precise shapes in materials like paper, cardboard, or thin metals are required, making it ideal for packaging, labels, and gaskets. Laser cutting offers superior versatility for intricate, custom designs across diverse materials, including acrylic, wood, and thicker metals, perfect for prototyping, detailed artwork, and small-batch manufacturing. Selecting between die cutting and laser cutting depends on production volume, material type, and design complexity, ensuring optimal efficiency and quality.

Choosing the Right Cutting Tool for Your Project

Die cutting offers precise, repeatable cuts ideal for high-volume projects requiring uniform shapes from materials like paper, fabric, or leather. Laser cutting provides versatility for complex designs and intricate details, excelling with metals, plastics, and wood while allowing customization without the need for physical dies. Selecting the right tool depends on budget, material type, design complexity, and project scale to optimize efficiency and finish quality.

Die Cutting vs Laser Cutting Infographic

productdif.com

productdif.com