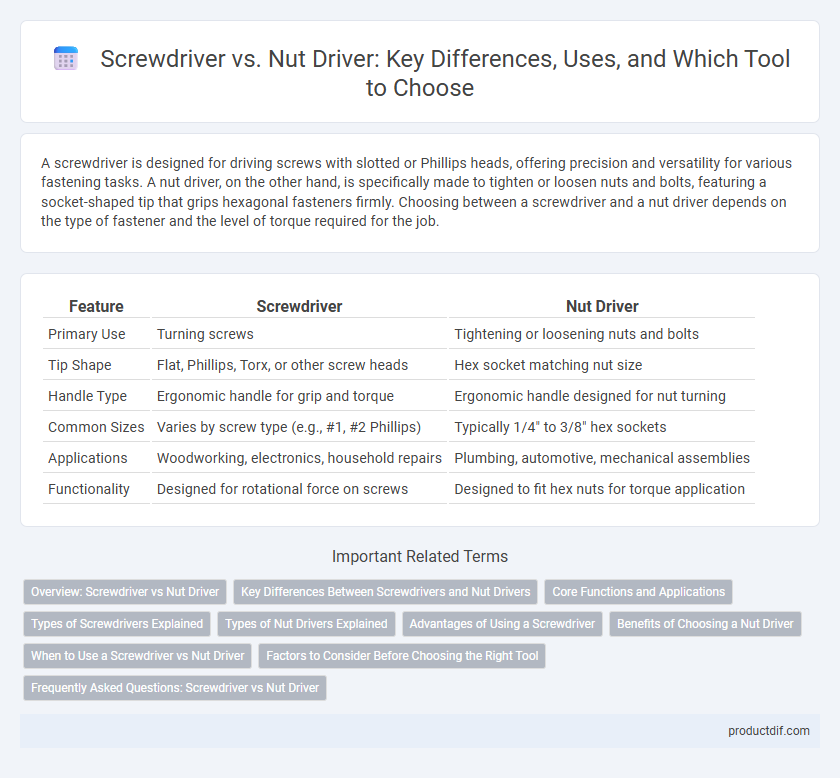

A screwdriver is designed for driving screws with slotted or Phillips heads, offering precision and versatility for various fastening tasks. A nut driver, on the other hand, is specifically made to tighten or loosen nuts and bolts, featuring a socket-shaped tip that grips hexagonal fasteners firmly. Choosing between a screwdriver and a nut driver depends on the type of fastener and the level of torque required for the job.

Table of Comparison

| Feature | Screwdriver | Nut Driver |

|---|---|---|

| Primary Use | Turning screws | Tightening or loosening nuts and bolts |

| Tip Shape | Flat, Phillips, Torx, or other screw heads | Hex socket matching nut size |

| Handle Type | Ergonomic handle for grip and torque | Ergonomic handle designed for nut turning |

| Common Sizes | Varies by screw type (e.g., #1, #2 Phillips) | Typically 1/4" to 3/8" hex sockets |

| Applications | Woodworking, electronics, household repairs | Plumbing, automotive, mechanical assemblies |

| Functionality | Designed for rotational force on screws | Designed to fit hex nuts for torque application |

Overview: Screwdriver vs Nut Driver

A screwdriver features a flat or Phillips head designed to drive screws of various sizes, offering precision and versatility in fastening tasks. A nut driver, resembling a small socket wrench, is specifically engineered to tighten or loosen hexagonal nuts and bolts, providing enhanced grip and torque. Understanding the functional differences between a screwdriver and a nut driver is essential for selecting the right tool for assembly, repair, or maintenance work.

Key Differences Between Screwdrivers and Nut Drivers

Screwdrivers feature a flat or Phillips head designed primarily for driving screws, while nut drivers have a socket tip that fits over nuts and bolts, enabling efficient tightening or loosening. The torque application differs, with nut drivers providing greater leverage for hexagonal fasteners, whereas screwdrivers offer precision control for screwheads. Material composition often varies, with nut drivers typically having hollow shafts to accommodate threaded fasteners, contrasting with the solid shafts of screwdrivers.

Core Functions and Applications

A screwdriver is primarily designed to insert and remove screws with various head types such as Phillips, flathead, and Torx, making it essential for general fastening tasks. Nut drivers are specifically engineered to tighten or loosen hexagonal nuts and bolts, offering a socket-like grip for increased torque without damaging fasteners. While screwdrivers excel in precision work with screws, nut drivers are better suited for mechanical applications involving nuts, bolts, and fasteners in automotive and appliance repair.

Types of Screwdrivers Explained

Screwdrivers come in various types, including flathead, Phillips, Torx, and hex, each designed to fit specific screw heads for optimal torque and precision. Flathead screwdrivers feature a single, flat blade ideal for slotted screws, while Phillips screwdrivers have a cross-shaped tip that provides better grip and prevents slipping. Torx and hex screwdrivers are commonly used in electronics and automotive applications for their ability to apply higher torque without damaging the screw.

Types of Nut Drivers Explained

Nut drivers come in various types, including T-handle, ratcheting, and socket nut drivers, each designed to provide better grip and torque control for fastening nuts and bolts. T-handle nut drivers offer enhanced leverage for tightening or loosening stubborn fasteners, while ratcheting nut drivers enable quick, continuous rotation without removing the tool from the fastener. Socket nut drivers resemble a deep socket wrench, ideal for recessed or hard-to-reach nuts, making them versatile for automotive, electrical, and household applications.

Advantages of Using a Screwdriver

A screwdriver offers greater versatility by accommodating various screw types and sizes, making it ideal for a wide range of applications from electronics to woodworking. Its slender design allows access to tight or recessed areas where larger tools like nut drivers may not fit. The wide availability of interchangeable tips also enhances precision and efficiency, reducing the need to switch tools frequently.

Benefits of Choosing a Nut Driver

Choosing a nut driver ensures precise torque application when tightening or loosening hexagonal nuts, reducing the risk of stripping fasteners compared to a screwdriver. Nut drivers provide a better grip and higher efficiency for repetitive tasks involving nuts and bolts, enhancing overall productivity. Their ergonomic design minimizes hand fatigue during prolonged use, making them ideal for mechanical and assembly work.

When to Use a Screwdriver vs Nut Driver

Use a screwdriver when fastening or loosening screws with slotted, Phillips, or other specialized heads found in wood, metal, or plastic surfaces. Opt for a nut driver to efficiently tighten or remove hexagonal nuts and bolts, especially in plumbing, electrical, and automotive applications where a socket grip is essential. Choosing the right tool enhances precision and reduces the risk of stripping or damaging fasteners during assembly or repair tasks.

Factors to Consider Before Choosing the Right Tool

Choosing between a screwdriver and a nut driver depends on the type of fasteners involved; screwdrivers are designed for slotted, Phillips, and Torx screws, while nut drivers are best suited for hexagonal nuts and bolts. Consider the torque requirement and access space, as nut drivers provide more leverage and grip on nuts without cam-out, whereas screwdrivers offer versatility for various screw heads. Material compatibility and handle ergonomics also impact efficiency and comfort during prolonged use, influencing the decision for precise or heavy-duty applications.

Frequently Asked Questions: Screwdriver vs Nut Driver

A screwdriver is designed primarily for driving screws with slotted, Phillips, or other shaped heads, while a nut driver is specifically made to tighten or loosen nuts and bolts with hexagonal heads. Common questions often address which tool to use for fasteners of certain sizes, the differences in handle design for torque application, and the interchangeability of bits between screwdrivers and nut drivers. Selecting the correct tool ensures efficient fastening, reduces wear on fasteners, and prevents damage to work surfaces.

Screwdriver vs Nut Driver Infographic

productdif.com

productdif.com