A spindle is the rotating axis of a machine tool that provides the power and motion needed for cutting or drilling operations, whereas a chuck is the device attached to the spindle that securely holds the workpiece or tool in place. Spindles are essential for delivering precision and speed, while chucks offer versatile gripping capabilities, allowing different sizes and shapes of materials to be machined accurately. Understanding the distinct roles of spindle and chuck is vital for optimizing tool performance and achieving high-quality machining results.

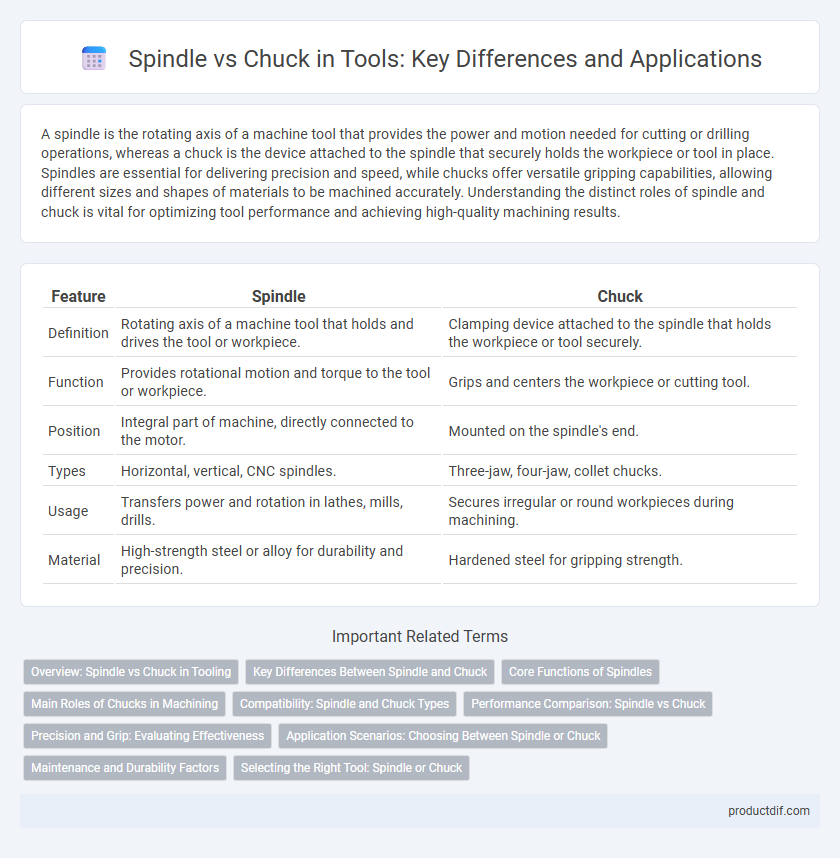

Table of Comparison

| Feature | Spindle | Chuck |

|---|---|---|

| Definition | Rotating axis of a machine tool that holds and drives the tool or workpiece. | Clamping device attached to the spindle that holds the workpiece or tool securely. |

| Function | Provides rotational motion and torque to the tool or workpiece. | Grips and centers the workpiece or cutting tool. |

| Position | Integral part of machine, directly connected to the motor. | Mounted on the spindle's end. |

| Types | Horizontal, vertical, CNC spindles. | Three-jaw, four-jaw, collet chucks. |

| Usage | Transfers power and rotation in lathes, mills, drills. | Secures irregular or round workpieces during machining. |

| Material | High-strength steel or alloy for durability and precision. | Hardened steel for gripping strength. |

Overview: Spindle vs Chuck in Tooling

A spindle is a rotating axis in a machine tool that holds and drives the cutting tool or workpiece, providing precision and stability during machining operations. A chuck is a specialized clamping device attached to the spindle, designed to grip and secure the workpiece or tool firmly in place. Understanding the spindle's rotational function and the chuck's gripping role is essential for optimizing tooling performance in manufacturing processes.

Key Differences Between Spindle and Chuck

The spindle is the rotating axis of a machine tool that holds and drives the cutting tool or workpiece, while the chuck is a clamping device attached to the spindle used to firmly grip the tool or workpiece. Spindle speed, torque, and precision directly affect machining accuracy, whereas chuck type and jaw design determine the grip stability and versatility for different shapes. Understanding the differences in function and mechanical roles is essential for selecting the right combination for CNC machines or lathes to optimize performance.

Core Functions of Spindles

Spindles serve as the primary rotating component in machinery, responsible for holding and driving the cutting tool or workpiece with precision and high-speed rotation. They provide critical functions such as torque generation, speed regulation, and vibration control to ensure accuracy and efficiency in machining operations. Unlike chucks, which secure the tool or workpiece, spindles deliver the core mechanical power necessary for tool movement and material removal.

Main Roles of Chucks in Machining

Chucks primarily serve to securely hold and clamp the workpiece during machining operations, ensuring precision and stability. They provide adjustable gripping mechanisms adaptable to various shapes and sizes, enabling accurate rotation and alignment. This secure holding minimizes vibrations and enhances machining quality compared to the spindle's role of rotating the tool or workpiece.

Compatibility: Spindle and Chuck Types

Spindle and chuck compatibility is crucial for optimal tool performance, with spindle types varying from Morse tapers to HSK and CAT, each designed to accommodate specific chuck designs. Chucks such as three-jaw, four-jaw, and collet chucks must match the spindle's taper or mounting system to ensure secure and precise workpiece holding. Selecting the correct spindle and chuck pairing enhances machining accuracy, reduces vibrations, and extends tool life.

Performance Comparison: Spindle vs Chuck

Spindle performance excels in rotational speed and precision, providing consistent torque for high-accuracy machining. Chuck performance offers superior grip strength and versatility, allowing quick workpiece changes and secure holding during heavy-duty operations. Comparing the two, spindles optimize rotational stability, while chucks ensure firm workpiece retention, making each essential for different stages of manufacturing processes.

Precision and Grip: Evaluating Effectiveness

The spindle provides high rotational precision essential for maintaining accuracy in CNC machining and lathe operations, ensuring consistent cutting performance. The chuck offers superior grip strength by securely clamping the workpiece, minimizing slippage during high-torque applications. Evaluating effectiveness requires balancing spindle precision with chuck grip quality based on specific machining tolerances and material properties.

Application Scenarios: Choosing Between Spindle or Chuck

Spindles are ideal for high-precision machining applications requiring continuous rotation and torque control, commonly used in CNC mills and lathes. Chucks excel in securely gripping irregularly shaped or cylindrical workpieces during drilling, turning, and milling, providing versatility in manual and automated setups. Selecting between a spindle or chuck depends on the workpiece geometry, machining process, and required accuracy in metalworking or woodworking environments.

Maintenance and Durability Factors

Spindle maintenance requires regular lubrication and alignment checks to prevent overheating and wear, ensuring operational longevity. Chucks demand frequent cleaning and jaw inspection to avoid debris buildup and jaw misalignment, which can compromise grip strength and precision. Durability of spindles hinges on robust bearings and high-quality materials, while chuck durability depends on corrosion-resistant components and sturdy jaw construction.

Selecting the Right Tool: Spindle or Chuck

Selecting the right tool between a spindle and chuck depends on the machining requirements and workpiece specifications. Spindles offer high precision and rigidity for high-speed operations, making them ideal for complex milling tasks. Chucks provide versatile and secure gripping for various workpiece shapes and are preferred for drilling or turning applications.

Spindle vs Chuck Infographic

productdif.com

productdif.com