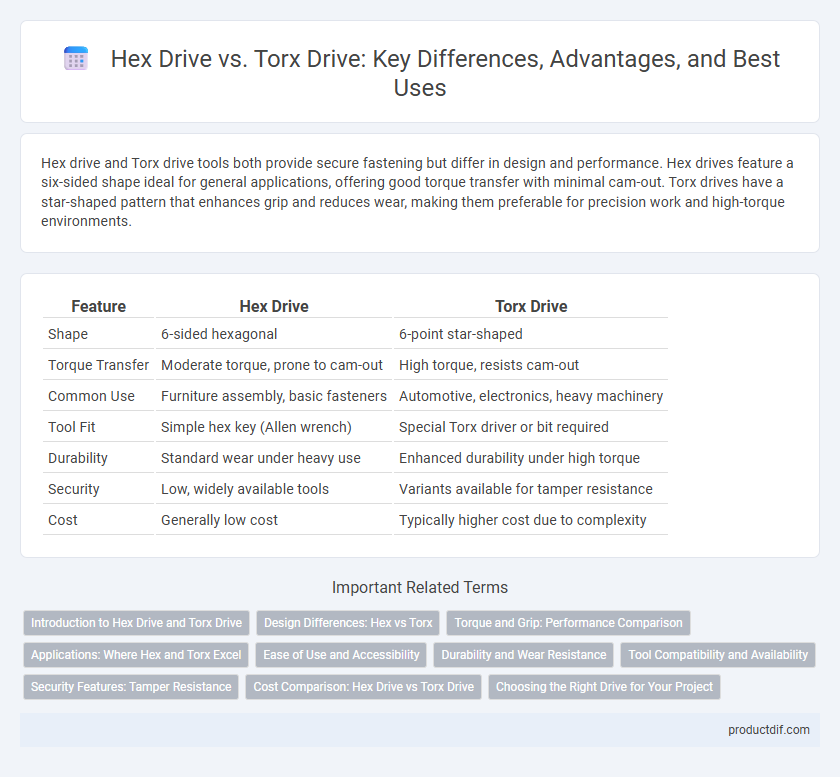

Hex drive and Torx drive tools both provide secure fastening but differ in design and performance. Hex drives feature a six-sided shape ideal for general applications, offering good torque transfer with minimal cam-out. Torx drives have a star-shaped pattern that enhances grip and reduces wear, making them preferable for precision work and high-torque environments.

Table of Comparison

| Feature | Hex Drive | Torx Drive |

|---|---|---|

| Shape | 6-sided hexagonal | 6-point star-shaped |

| Torque Transfer | Moderate torque, prone to cam-out | High torque, resists cam-out |

| Common Use | Furniture assembly, basic fasteners | Automotive, electronics, heavy machinery |

| Tool Fit | Simple hex key (Allen wrench) | Special Torx driver or bit required |

| Durability | Standard wear under heavy use | Enhanced durability under high torque |

| Security | Low, widely available tools | Variants available for tamper resistance |

| Cost | Generally low cost | Typically higher cost due to complexity |

Introduction to Hex Drive and Torx Drive

Hex drive uses a six-sided hexagonal shape designed for high-torque applications and is commonly found in Allen wrenches and screws. Torx drive features a star-shaped pattern with six rounded points that provide better grip and reduced cam-out compared to hex drives. Both drives are widely used in automotive and electronics industries to ensure secure and efficient fastening.

Design Differences: Hex vs Torx

Hex drive fasteners feature a simple six-sided shape designed for basic torque applications, offering ease of alignment and compatibility with standard hex wrenches. Torx drive fasteners possess a star-shaped, six-point design that distributes torque more evenly across the surface, reducing cam-out and allowing for higher torque transfer. The Torx design's intricate geometry enhances grip and durability compared to the straightforward flat surfaces of hex drives.

Torque and Grip: Performance Comparison

Hex drives deliver strong torque transmission due to their six-sided shape, providing excellent grip and reducing the risk of cam-out in high-torque applications. Torx drives feature a star-shaped pattern with six rounded points, which distributes torque evenly across the fastener, enhancing grip and allowing higher torque levels without damaging the tool or fastener. In performance comparisons, Torx drives typically outperform hex drives in maintaining consistent torque and reducing tool wear under heavy load conditions.

Applications: Where Hex and Torx Excel

Hex drives excel in applications requiring strong torque transmission and are commonly used in automotive repair, machinery assembly, and furniture construction due to their simple, six-sided design that fits securely with standard Allen wrenches. Torx drives provide superior resistance to cam-out, making them ideal for electronics manufacturing, automotive engines, and aerospace components where precision and durability under high torque are critical. Both drives optimize fastening performance but are chosen based on specific industry demands, with Torx favored for high-torque, high-precision environments and Hex preferred for general-purpose mechanical tasks.

Ease of Use and Accessibility

Hex drive tools offer straightforward design and widespread compatibility with standard Allen keys, making them highly accessible for basic tasks and quick fixes. Torx drive tools provide enhanced grip and reduced cam-out risk, which improves ease of use during high-torque applications and precision assembly. Users often prefer Torx for repetitive or heavy-duty jobs, while Hex remains favored for general-purpose or DIY accessibility.

Durability and Wear Resistance

Hex drive tools exhibit high durability and wear resistance due to their simple six-point design, which evenly distributes torque and reduces cam-out. Torx drive tools, featuring a star-shaped pattern with multiple contact points, provide superior wear resistance by minimizing tool slip and enhancing torque transfer efficiency. In heavy-duty applications, Torx drives generally outperform hex drives in maintaining tool integrity and longevity under repeated stress.

Tool Compatibility and Availability

Hex Drive tools offer widespread compatibility with common fasteners and are available in almost all hardware stores, making them a versatile choice for general use. Torx Drive tools provide superior grip and torque transfer for specialized fasteners, but their availability is more limited compared to Hex Drives, especially in basic tool sets. Professionals often prefer Torx for automotive and electronics applications due to enhanced fastening performance, while Hex remains the go-to for broad compatibility and easier access.

Security Features: Tamper Resistance

Hex Drive tools feature a simple six-sided design that offers basic tamper resistance but can be easily compromised with common tools. Torx Drive tools incorporate a star-shaped pattern with a pin in the center, significantly enhancing security by deterring tampering and unauthorized removal. This unique configuration makes Torx Drive the preferred choice in applications requiring robust tamper resistance and secure fastening.

Cost Comparison: Hex Drive vs Torx Drive

Hex drive tools typically offer a lower initial cost compared to Torx drive tools due to simpler manufacturing processes and widespread availability. Torx drive tools, while often more expensive upfront, provide enhanced torque transfer and reduced cam-out, potentially lowering long-term maintenance costs. Evaluating total cost of ownership, including tool durability and application efficiency, is essential when comparing Hex drive versus Torx drive investments.

Choosing the Right Drive for Your Project

Selecting the right drive for your project depends on factors like application type, torque requirements, and fastener design. Hex drives offer simplicity and compatibility with common hand tools, ideal for low to medium torque tasks, whereas Torx drives provide superior torque transfer and reduced cam-out, making them optimal for high-torque or precision applications. Evaluating fastener accessibility and the potential for tool slippage ensures efficient, damage-free fastening with your chosen drive system.

Hex Drive vs Torx Drive Infographic

productdif.com

productdif.com