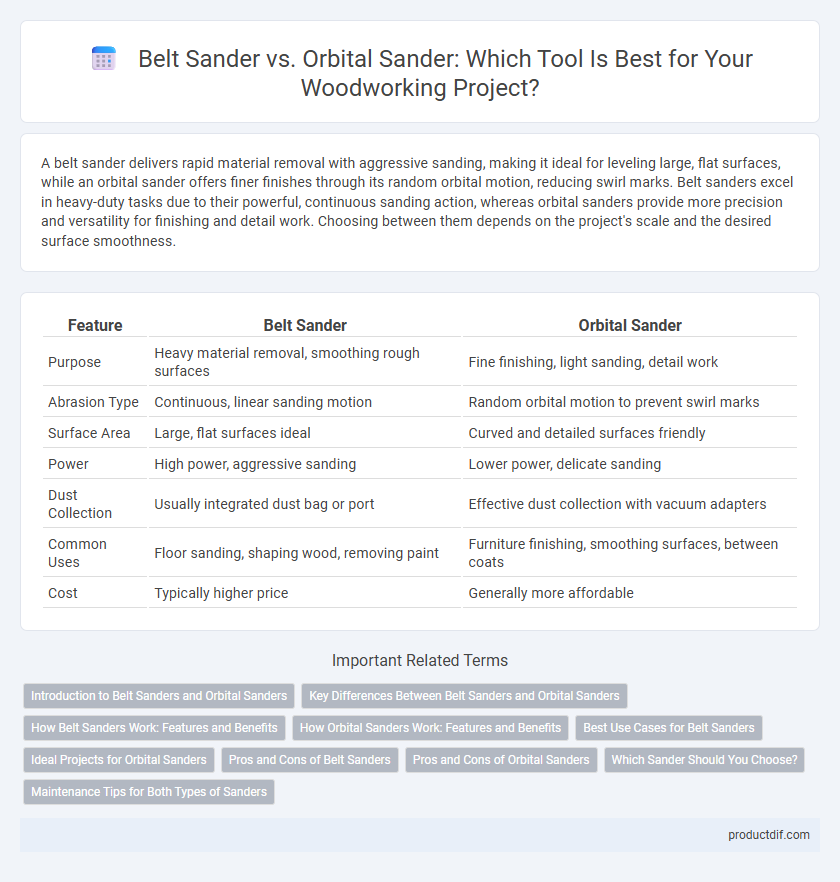

A belt sander delivers rapid material removal with aggressive sanding, making it ideal for leveling large, flat surfaces, while an orbital sander offers finer finishes through its random orbital motion, reducing swirl marks. Belt sanders excel in heavy-duty tasks due to their powerful, continuous sanding action, whereas orbital sanders provide more precision and versatility for finishing and detail work. Choosing between them depends on the project's scale and the desired surface smoothness.

Table of Comparison

| Feature | Belt Sander | Orbital Sander |

|---|---|---|

| Purpose | Heavy material removal, smoothing rough surfaces | Fine finishing, light sanding, detail work |

| Abrasion Type | Continuous, linear sanding motion | Random orbital motion to prevent swirl marks |

| Surface Area | Large, flat surfaces ideal | Curved and detailed surfaces friendly |

| Power | High power, aggressive sanding | Lower power, delicate sanding |

| Dust Collection | Usually integrated dust bag or port | Effective dust collection with vacuum adapters |

| Common Uses | Floor sanding, shaping wood, removing paint | Furniture finishing, smoothing surfaces, between coats |

| Cost | Typically higher price | Generally more affordable |

Introduction to Belt Sanders and Orbital Sanders

Belt sanders utilize a continuous loop of sandpaper driven by a motor, ideal for heavy-duty material removal and smoothing large, flat surfaces quickly. Orbital sanders feature a circular sanding pad that moves in small orbits, providing finer finishes with less risk of gouging the wood. Both tools serve unique purposes in woodworking and metalworking, with belt sanders excelling in rapid stock removal and orbital sanders preferred for detailed finish work.

Key Differences Between Belt Sanders and Orbital Sanders

Belt sanders feature a continuous loop of sandpaper that moves in a straight line, making them ideal for rapid material removal and shaping large, flat surfaces. Orbital sanders use a round sanding pad that moves in small orbits, providing a finer finish while minimizing swirl marks, best suited for finishing and sanding curved or uneven surfaces. Belt sanders excel in heavy-duty tasks with high power and aggressive sanding, whereas orbital sanders prioritize precision and smoothness for detailed woodworking and finishing projects.

How Belt Sanders Work: Features and Benefits

Belt sanders operate using a continuous loop of sandpaper stretched over two drums, powered by a motor that rapidly spins the belt to remove material efficiently from surfaces. Their aggressive sanding action excels at leveling rough wood, shaping edges, and removing old finishes quickly, making them ideal for heavy-duty tasks. Features such as variable speed control, dust collection systems, and ergonomic grips enhance user comfort and precision during prolonged use.

How Orbital Sanders Work: Features and Benefits

Orbital sanders operate using a sanding pad that moves in a random orbital pattern, preventing swirl marks and providing a smooth finish on wood, metal, or plastic surfaces. These sanders are equipped with adjustable speed settings and dust collection systems, enhancing precision and cleanliness during sanding tasks. Their lightweight design and ergonomic handles improve user control, making them ideal for detailed work and finishing projects.

Best Use Cases for Belt Sanders

Belt sanders excel at heavy-duty material removal, making them ideal for leveling rough surfaces, removing old paint or varnish, and shaping wood quickly. Their continuous loop of sandpaper allows for aggressive sanding on large, flat areas, which outperforms orbital sanders in speed and power. While not suited for fine finishing, belt sanders are the best choice for initial stages of sanding where significant stock needs to be removed efficiently.

Ideal Projects for Orbital Sanders

Orbital sanders excel in fine finishing tasks such as smoothing furniture surfaces, preparing walls for painting, and refinishing cabinets due to their random orbital motion that minimizes swirl marks. These tools are ideal for delicate woodwork, curved edges, and detailed trim where precision and a smooth finish are critical. Their lightweight design and ease of control make them perfect for hobbyists and professionals working on medium to small-sized projects.

Pros and Cons of Belt Sanders

Belt sanders offer powerful, aggressive material removal ideal for shaping and leveling large surfaces quickly. They excel in heavy-duty tasks but can leave visible scratches and require careful control to avoid gouging. Their bulkier design and higher noise levels make them less suitable for delicate or detailed sanding compared to orbital sanders.

Pros and Cons of Orbital Sanders

Orbital sanders excel in producing smooth finishes on wooden surfaces due to their random orbital motion, which minimizes swirl marks and ensures even sanding. They are lightweight and easy to handle, making them ideal for detailed work and fine finishing, but they generally remove material slower compared to belt sanders. Their dust collection efficiency improves worksite cleanliness, although their smaller sanding pads limit their effectiveness on large, rough surfaces.

Which Sander Should You Choose?

When deciding between a belt sander and an orbital sander, consider the project requirements and material type; belt sanders excel at rapid material removal on large, flat surfaces, while orbital sanders provide smoother finishes with less aggressive sanding ideal for wood and delicate surfaces. Belt sanders use a continuous loop of sandpaper for heavy-duty stripping and shaping tasks, whereas orbital sanders use a circular, random orbit motion to minimize swirl marks. Prioritize a belt sander for rough sanding and an orbital sander for fine finishing to achieve optimal results.

Maintenance Tips for Both Types of Sanders

Regularly clean the dust collection system and inspect sanding belts or discs for wear to prolong the life of both belt sanders and orbital sanders. Lubricate moving parts as recommended by the manufacturer to prevent friction damage and ensure smooth operation. Store tools in a dry environment to avoid rust and electrical issues, enhancing durability and performance.

belt sander vs orbital sander Infographic

productdif.com

productdif.com