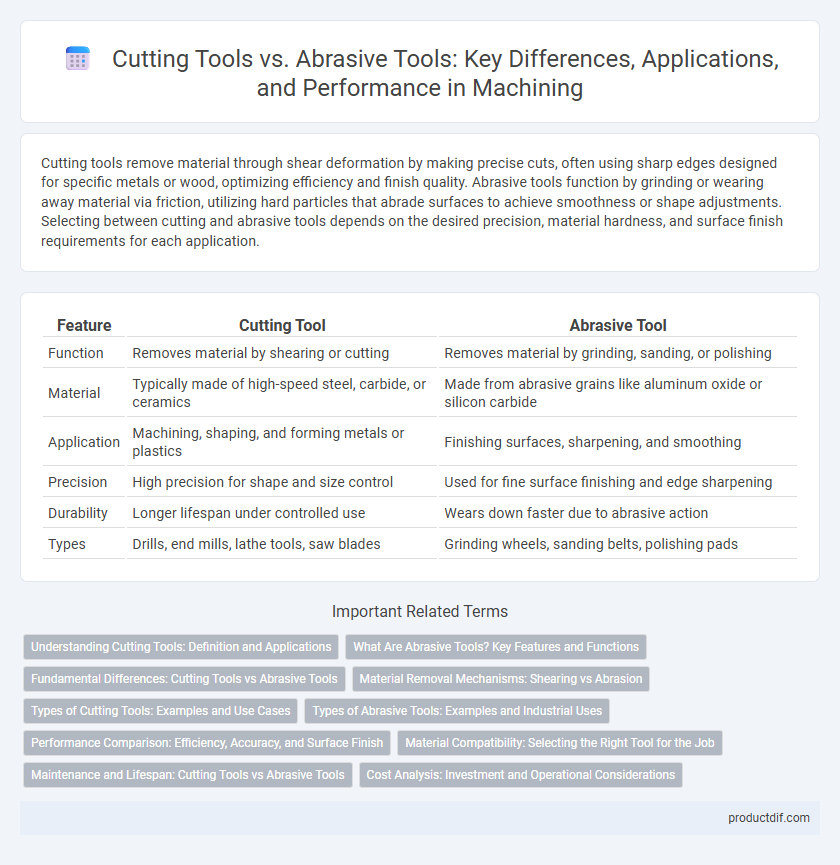

Cutting tools remove material through shear deformation by making precise cuts, often using sharp edges designed for specific metals or wood, optimizing efficiency and finish quality. Abrasive tools function by grinding or wearing away material via friction, utilizing hard particles that abrade surfaces to achieve smoothness or shape adjustments. Selecting between cutting and abrasive tools depends on the desired precision, material hardness, and surface finish requirements for each application.

Table of Comparison

| Feature | Cutting Tool | Abrasive Tool |

|---|---|---|

| Function | Removes material by shearing or cutting | Removes material by grinding, sanding, or polishing |

| Material | Typically made of high-speed steel, carbide, or ceramics | Made from abrasive grains like aluminum oxide or silicon carbide |

| Application | Machining, shaping, and forming metals or plastics | Finishing surfaces, sharpening, and smoothing |

| Precision | High precision for shape and size control | Used for fine surface finishing and edge sharpening |

| Durability | Longer lifespan under controlled use | Wears down faster due to abrasive action |

| Types | Drills, end mills, lathe tools, saw blades | Grinding wheels, sanding belts, polishing pads |

Understanding Cutting Tools: Definition and Applications

Cutting tools are precision instruments designed to remove material from a workpiece through shear deformation, typically crafted from high-speed steel, carbide, or ceramic materials to ensure durability and sharpness. They are essential in machining processes such as turning, milling, drilling, and shaping, achieving precise dimensions and surface finishes. Unlike abrasive tools that rely on grinding action, cutting tools maintain a defined cutting edge for efficient material removal in metalworking and manufacturing industries.

What Are Abrasive Tools? Key Features and Functions

Abrasive tools use hard particles bonded on a surface to cut, grind, or smooth materials by friction rather than shear. Key features include high hardness, precision shaping, and the ability to work on very hard or brittle materials such as metals, ceramics, and glass. Common abrasive tools are grinding wheels, sandpaper, and abrasive belts, which function in metal finishing, sharpening, and surface preparation processes.

Fundamental Differences: Cutting Tools vs Abrasive Tools

Cutting tools remove material by shearing with a sharp edge, creating precise shapes and finishes, commonly used in machining metals and plastics. Abrasive tools cut through grinding, sanding, or polishing by wearing away material using abrasive particles bonded to a surface, ideal for hard materials like ceramics or hardened steel. The fundamental difference lies in cutting tools employing a defined edge for material removal, while abrasive tools rely on friction and micro-cutting from abrasive grains.

Material Removal Mechanisms: Shearing vs Abrasion

Cutting tools remove material primarily through shearing, where a sharp edge applies concentrated force to separate chips from the workpiece. Abrasive tools rely on abrasion, where numerous hard particles slide or roll against the surface, progressively wearing it away by micro-cutting or plowing actions. Understanding these distinct material removal mechanisms is crucial for selecting the appropriate tool in machining and finishing processes.

Types of Cutting Tools: Examples and Use Cases

Cutting tools include drills, lathes, and milling cutters used to shape materials through precise material removal, commonly applied in metalworking and woodworking. Abrasive tools such as grinding wheels, sandpaper, and abrasive belts function by wearing away surface layers, ideal for finishing and smoothing operations on metals, ceramics, and composites. Each cutting tool type is selected based on material hardness, desired surface finish, and manufacturing accuracy requirements.

Types of Abrasive Tools: Examples and Industrial Uses

Types of abrasive tools include grinding wheels, abrasive belts, and abrasive brushes, each designed for specific material removal tasks. Grinding wheels are widely used in metal fabrication for surface finishing and shaping, while abrasive belts excel in sanding wood and smoothing metal surfaces. Abrasive brushes find applications in cleaning and deburring complex geometries in automotive and aerospace industries.

Performance Comparison: Efficiency, Accuracy, and Surface Finish

Cutting tools excel in efficiency and accuracy by removing material through shear deformation, providing precise dimensions and cleaner edges ideal for machining metals and plastics. Abrasive tools outperform in surface finish quality, using micro-cutting and grinding actions to achieve finer textures and remove minute imperfections. Efficiency in material removal is generally higher with cutting tools, while abrasive tools offer superior control over surface roughness and tolerance for hard or brittle materials.

Material Compatibility: Selecting the Right Tool for the Job

Cutting tools excel in machining metals such as steel, aluminum, and titanium, providing precise, clean cuts due to their sharp edges and rigid structure. Abrasive tools suit harder, brittle materials like ceramics, glass, and composites by grinding or polishing surfaces without excessive force. Choosing the correct tool depends on material hardness, brittleness, and required finish, ensuring efficiency and tool longevity.

Maintenance and Lifespan: Cutting Tools vs Abrasive Tools

Cutting tools typically require regular sharpening and edge maintenance to sustain precision and prolong lifespan, as dull edges can cause inefficient cuts and tool damage. Abrasive tools depend on consistent dressing to expose fresh abrasive grains, ensuring effective material removal and preventing glazing that reduces cutting efficiency. Proper maintenance directly influences the durability of both tool types, with cutting tools often lasting longer when well-maintained, while abrasive tools wear progressively during use and need periodic replacement.

Cost Analysis: Investment and Operational Considerations

Cutting tools typically require a significant initial investment due to their precision manufacturing but offer lower operational costs through longer tool life and less frequent replacements. Abrasive tools tend to have lower upfront costs but incur higher expenses over time because of faster wear rates and increased power consumption. A thorough cost analysis must weigh the balance between these investment and operational factors to optimize total expenditure in manufacturing processes.

Cutting Tool vs Abrasive Tool Infographic

productdif.com

productdif.com