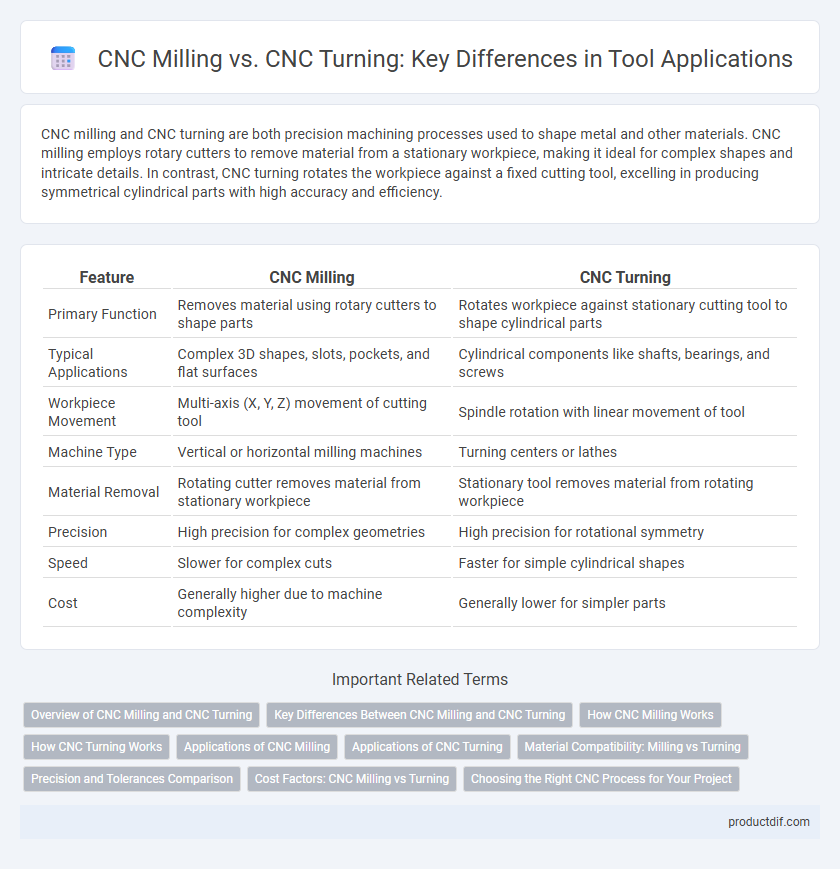

CNC milling and CNC turning are both precision machining processes used to shape metal and other materials. CNC milling employs rotary cutters to remove material from a stationary workpiece, making it ideal for complex shapes and intricate details. In contrast, CNC turning rotates the workpiece against a fixed cutting tool, excelling in producing symmetrical cylindrical parts with high accuracy and efficiency.

Table of Comparison

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Primary Function | Removes material using rotary cutters to shape parts | Rotates workpiece against stationary cutting tool to shape cylindrical parts |

| Typical Applications | Complex 3D shapes, slots, pockets, and flat surfaces | Cylindrical components like shafts, bearings, and screws |

| Workpiece Movement | Multi-axis (X, Y, Z) movement of cutting tool | Spindle rotation with linear movement of tool |

| Machine Type | Vertical or horizontal milling machines | Turning centers or lathes |

| Material Removal | Rotating cutter removes material from stationary workpiece | Stationary tool removes material from rotating workpiece |

| Precision | High precision for complex geometries | High precision for rotational symmetry |

| Speed | Slower for complex cuts | Faster for simple cylindrical shapes |

| Cost | Generally higher due to machine complexity | Generally lower for simpler parts |

Overview of CNC Milling and CNC Turning

CNC milling uses rotary cutters to remove material from a workpiece, creating complex shapes and features with high precision, ideal for parts with multiple surfaces. CNC turning involves rotating the workpiece while a stationary cutting tool shapes its exterior, primarily used for cylindrical components such as shafts and screws. Both methods leverage computer numerical control to enhance accuracy, repeatability, and efficiency in manufacturing processes.

Key Differences Between CNC Milling and CNC Turning

CNC milling machines use rotary cutters to remove material from a stationary workpiece, ideal for creating complex shapes and surfaces. CNC turning involves rotating the workpiece while a stationary cutting tool shapes it, suited for cylindrical or symmetrical objects. Key differences include the tool movement patterns, types of parts produced, and precision in handling intricate designs versus rotational symmetry.

How CNC Milling Works

CNC milling operates by rotating a cutting tool against a stationary workpiece to remove material and create complex shapes with high precision. The machine uses computer-controlled movements along multiple axes, typically three to five, enabling intricate contouring and surface finishes. This process is ideal for producing flat, irregular, or curved surfaces on metals, plastics, and composites.

How CNC Turning Works

CNC turning operates by rotating the workpiece on a spindle while a stationary cutting tool shapes the material, allowing precise cylindrical and conical parts to be produced efficiently. This process uses computer-controlled movements to adjust the tool's position and speed, ensuring high accuracy and repeatability in complex geometries. CNC turning excels in producing components like shafts, bushings, and threaded parts by removing material from the outer diameter or internal surfaces.

Applications of CNC Milling

CNC milling excels in complex 3D surface machining, making it ideal for automotive parts, aerospace components, and custom prototypes requiring intricate shapes and fine details. Its versatility allows precise cutting of various materials such as aluminum, steel, and plastics, enabling production of engine blocks, molds, and medical devices. CNC milling machines support multiple axes, enhancing precision and efficiency in manufacturing intricate geometries and multi-faceted designs.

Applications of CNC Turning

CNC turning is extensively used in producing cylindrical parts such as shafts, bushings, and pulleys with high precision and repeatability. This process excels in manufacturing components for automotive, aerospace, and medical industries, where tight tolerances and complex geometries are crucial. CNC turning can efficiently handle operations like threading, grooving, and parting, making it ideal for creating intricate rotationally symmetrical parts.

Material Compatibility: Milling vs Turning

CNC milling excels in machining complex shapes from a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites, thanks to its multi-axis cutting capability. CNC turning is ideal for producing cylindrical parts from materials such as stainless steel, brass, and other metals, offering high precision and surface finish for rotational components. Material compatibility depends on part geometry and production requirements, with milling preferred for intricate detailing and turning favored for symmetrical, round parts.

Precision and Tolerances Comparison

CNC milling offers higher precision for complex geometries with tight tolerances typically around +-0.005 mm, making it ideal for intricate parts requiring multi-axis operations. CNC turning excels in achieving superior roundness and surface finish, maintaining tolerances of approximately +-0.002 mm due to continuous rotation and steady cutting forces. Both technologies provide exceptional accuracy, but selection depends on part complexity, with milling favored for detailed features and turning preferred for symmetrical cylindrical components.

Cost Factors: CNC Milling vs Turning

CNC milling generally incurs higher costs than CNC turning due to more complex machine components and longer processing times associated with intricate geometries. Tooling expenses are typically greater in milling, driven by the need for multiple cutting tools and frequent replacements. Material waste and labor factors also influence overall expenses, with milling often generating more scrap and requiring more operator intervention compared to turning operations.

Choosing the Right CNC Process for Your Project

Selecting the appropriate CNC process depends on your project's specific needs, with CNC milling excelling at creating complex 3D shapes by cutting away material from a stationary workpiece using rotating tools. CNC turning is ideal for producing symmetrical parts and cylindrical shapes by rotating the workpiece against a cutting tool, enabling high precision in diameter and length. Evaluating factors like project geometry, tolerances, production volume, and material type ensures optimal efficiency and cost-effectiveness in machining.

CNC Milling vs CNC Turning Infographic

productdif.com

productdif.com