A table saw excels at making precise rip cuts and can handle larger pieces of wood, making it ideal for woodworking projects requiring straight, long cuts. A miter saw offers exceptional accuracy for crosscuts and angled cuts, perfect for tasks like framing, molding, and trim work. Choosing between the two depends on the type of cuts needed and the scale of the project.

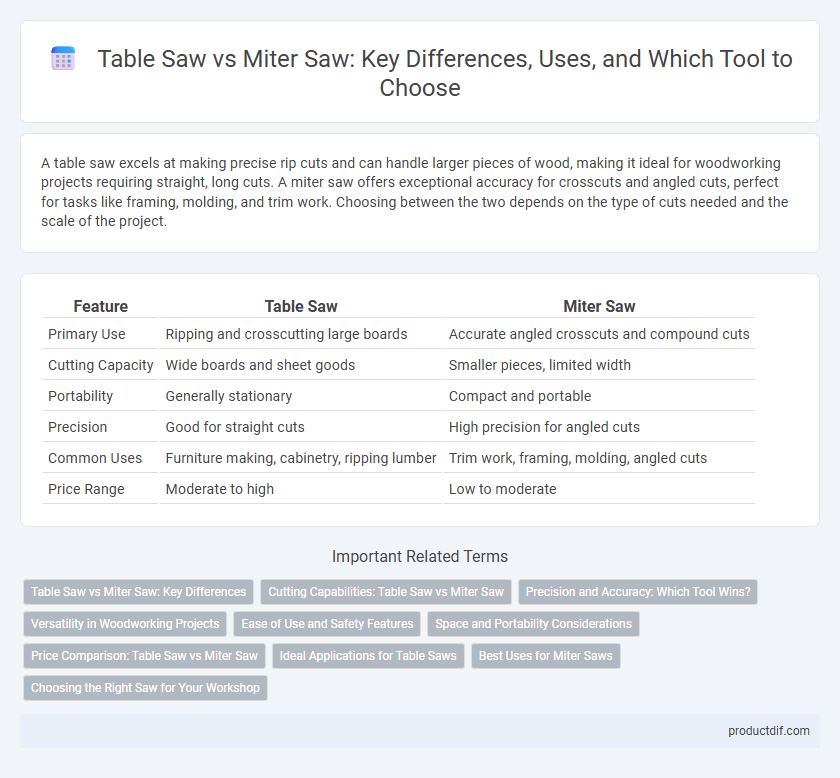

Table of Comparison

| Feature | Table Saw | Miter Saw |

|---|---|---|

| Primary Use | Ripping and crosscutting large boards | Accurate angled crosscuts and compound cuts |

| Cutting Capacity | Wide boards and sheet goods | Smaller pieces, limited width |

| Portability | Generally stationary | Compact and portable |

| Precision | Good for straight cuts | High precision for angled cuts |

| Common Uses | Furniture making, cabinetry, ripping lumber | Trim work, framing, molding, angled cuts |

| Price Range | Moderate to high | Low to moderate |

Table Saw vs Miter Saw: Key Differences

Table saws feature a large, flat surface with a circular blade that extends through the tabletop, ideal for ripping and cross-cutting large sheets of wood. Miter saws have a pivoting arm and a circular blade designed for making precise angled cuts, commonly used for molding, trim, and framing. While table saws excel at versatility and handling big materials, miter saws provide greater accuracy for angled and bevel cuts.

Cutting Capabilities: Table Saw vs Miter Saw

Table saws excel at making long, rip cuts and can handle larger materials, providing versatile cutting capabilities for woodworking projects. Miter saws specialize in precise crosscuts and angled cuts, ideal for trim work and framing tasks that require accuracy. Each tool's cutting capacity is optimized for different applications, making the choice dependent on the specific type of cut and material size needed.

Precision and Accuracy: Which Tool Wins?

Table saws provide superior precision for long, straight cuts due to their stable fence and large cutting surface, ensuring consistent accuracy in rip cuts. Miter saws excel in angled crosscuts and bevels with high accuracy, thanks to adjustable miter gauges and detents for common angles. When comparing precision and accuracy, table saws dominate in straight, repeatable cuts while miter saws lead in precise angled cuts and compound bevels.

Versatility in Woodworking Projects

Table saws offer superior versatility in woodworking by enabling rip cuts, crosscuts, and bevel cuts on large wood sheets, which makes them essential for furniture making and cabinetry. Miter saws excel in precision crosscuts and angled cuts, ideal for framing and detailed trim work. Woodworkers benefit from using both tools to achieve a wide range of cuts necessary for diverse projects.

Ease of Use and Safety Features

Table saws offer versatile cutting capabilities but require careful handling due to exposed blades, making safety features like blade guards, anti-kickback pawls, and riving knives essential for reducing accidents. Miter saws prioritize ease of use with intuitive pivoting arms and built-in fences for precise angle cuts, coupled with safety elements such as blade covers and electric brakes to quickly stop the blade. Both tools demand attention to safety protocols, but miter saws generally provide a more user-friendly experience for beginners with enhanced protective mechanisms.

Space and Portability Considerations

Table saws typically require a larger workspace due to their bulkier design and heavier weight, making them less portable and more suited for stationary setups. Miter saws are compact, lightweight, and often equipped with handles, enhancing portability and allowing for easy transportation between job sites. When space is limited or frequent mobility is needed, miter saws offer a more convenient solution compared to table saws.

Price Comparison: Table Saw vs Miter Saw

Table saws generally have a higher price range, starting around $300 and reaching over $1,500 for professional models, while miter saws typically cost between $100 and $600. Budget-conscious users often prefer miter saws due to their affordability and specialized cutting capabilities for precise crosscuts and angles. Investing in a table saw offers greater versatility for ripping, crosscutting, and dado cuts, which may justify the higher cost for woodworking professionals.

Ideal Applications for Table Saws

Table saws excel in making precise, long rip cuts and crosscuts on large sheets of plywood, MDF, and hardwood, making them ideal for cabinetry and furniture making. Their adjustable fences and high blade height allow for versatile cuts, including bevel and dado joints, essential in detailed woodworking projects. The powerful motor and stable table surface ensure consistent accuracy when cutting thick or multiple stacked materials.

Best Uses for Miter Saws

Miter saws excel in making precise crosscuts and angled cuts, especially in woodworking and framing projects. They are ideal for cutting molding, trim, and other finishing materials where accuracy and clean edges are crucial. Compared to table saws, miter saws offer superior control for repetitive angle cuts and compound cuts.

Choosing the Right Saw for Your Workshop

Table saws provide powerful ripping capabilities and precise straight cuts essential for large sheet materials, while miter saws excel in making accurate crosscuts and angled cuts on smaller wood pieces. Selecting the right saw depends on your workshop projects: choose a table saw for versatility in cutting full-size panels and a miter saw for efficient, repeatable angled cuts and trimming. Consider your space, types of materials, and common cut requirements to optimize workflow and precision.

table saw vs miter saw Infographic

productdif.com

productdif.com