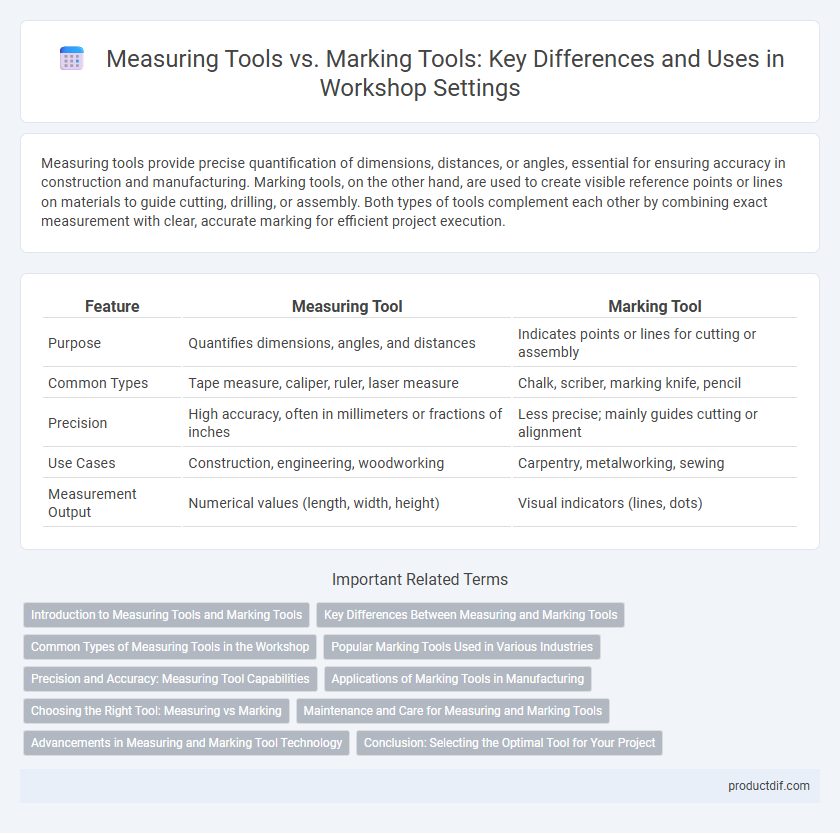

Measuring tools provide precise quantification of dimensions, distances, or angles, essential for ensuring accuracy in construction and manufacturing. Marking tools, on the other hand, are used to create visible reference points or lines on materials to guide cutting, drilling, or assembly. Both types of tools complement each other by combining exact measurement with clear, accurate marking for efficient project execution.

Table of Comparison

| Feature | Measuring Tool | Marking Tool |

|---|---|---|

| Purpose | Quantifies dimensions, angles, and distances | Indicates points or lines for cutting or assembly |

| Common Types | Tape measure, caliper, ruler, laser measure | Chalk, scriber, marking knife, pencil |

| Precision | High accuracy, often in millimeters or fractions of inches | Less precise; mainly guides cutting or alignment |

| Use Cases | Construction, engineering, woodworking | Carpentry, metalworking, sewing |

| Measurement Output | Numerical values (length, width, height) | Visual indicators (lines, dots) |

Introduction to Measuring Tools and Marking Tools

Measuring tools like calipers, micrometers, and tape measures provide precise numerical data essential for accurate dimensions in construction, manufacturing, and craftsmanship. Marking tools such as scribes, punches, and marking gauges transfer measurements onto materials, ensuring guidelines for cutting or shaping. Understanding the distinct roles of measuring and marking tools enhances accuracy and efficiency in various technical and industrial applications.

Key Differences Between Measuring and Marking Tools

Measuring tools precisely quantify dimensions, angles, or distances using units such as inches or millimeters, with instruments like calipers, rulers, and micrometers. Marking tools are designed to indicate cutting lines or reference points on materials without measurement, including scribes, marking gauges, and chalk. The key difference lies in their function: measuring tools provide exact numerical data, while marking tools create visible guides for fabrication or assembly.

Common Types of Measuring Tools in the Workshop

Common types of measuring tools in the workshop include tape measures, calipers, rulers, and micrometers, each designed for specific precision tasks. Tape measures offer flexibility for longer distances, while calipers and micrometers provide highly accurate measurements for small dimensions. Rulers are universally used for quick, straightforward measurement tasks on various materials.

Popular Marking Tools Used in Various Industries

Popular marking tools used in various industries include permanent markers, chalk, scribing tools, and laser markers, each chosen for their precision and material compatibility. Industries like construction rely heavily on chalk lines for quick, visible guides, while engineering fields favor scribing tools for detailed metalwork. Laser markers are increasingly preferred in manufacturing for their accuracy and ability to mark delicate surfaces without damage.

Precision and Accuracy: Measuring Tool Capabilities

Measuring tools such as calipers and micrometers provide high precision and accuracy by delivering exact numerical readings essential for quality control and dimensional inspection. Marking tools, including scribes and marking knives, offer precision primarily in layout and guiding cuts but lack the quantitative accuracy of measuring instruments. The inherent capability of measuring tools to quantify dimensions makes them indispensable for precise engineering and manufacturing processes.

Applications of Marking Tools in Manufacturing

Marking tools in manufacturing are essential for creating precise reference points on materials, enabling accurate cutting, machining, and assembly processes. Common applications include scribing lines on metal surfaces, engraving identification marks, and layout lines for welding or drilling. These tools improve workflow efficiency and ensure consistent product quality by providing clear guides for subsequent operations.

Choosing the Right Tool: Measuring vs Marking

Choosing the right tool involves understanding the distinct functions of measuring and marking tools; measuring tools like calipers and tape measures provide precise dimensions essential for accuracy, while marking tools such as scribes and pencils create visible guides on materials for cutting or assembly. Measuring tools ensure exactness in size and distance, critical in engineering and construction, whereas marking tools translate those measurements into actionable marks directly on the workpiece. Selecting appropriate tools based on task requirements enhances workflow efficiency and minimizes errors in fabrication and assembly processes.

Maintenance and Care for Measuring and Marking Tools

Proper maintenance of measuring tools involves regular calibration, cleaning, and storage in protective cases to ensure accuracy and longevity. Marking tools require frequent blade or tip sharpening and protection from rust or damage by storing in dry environments and using protective caps. Both tool types benefit from routine inspection to detect wear or damage, preventing inaccurate measurements or markings during precision tasks.

Advancements in Measuring and Marking Tool Technology

Advancements in measuring tools have introduced laser-based precision devices that enhance accuracy and reduce human error in industrial applications. Meanwhile, marking tools now incorporate digital interfaces and automated engraving technology, enabling faster and more detailed customization on various materials. Integration of IoT and smart sensors further optimizes both measuring and marking tools for real-time data collection and seamless workflow management.

Conclusion: Selecting the Optimal Tool for Your Project

Choosing the right tool between measuring tools and marking tools depends on project requirements for precision and layout. Measuring tools provide accuracy in dimensions and distances, essential for ensuring components fit correctly. Marking tools, on the other hand, facilitate clear, visible guides for cutting or assembly, improving workflow efficiency and reducing errors.

Measuring Tool vs Marking Tool Infographic

productdif.com

productdif.com