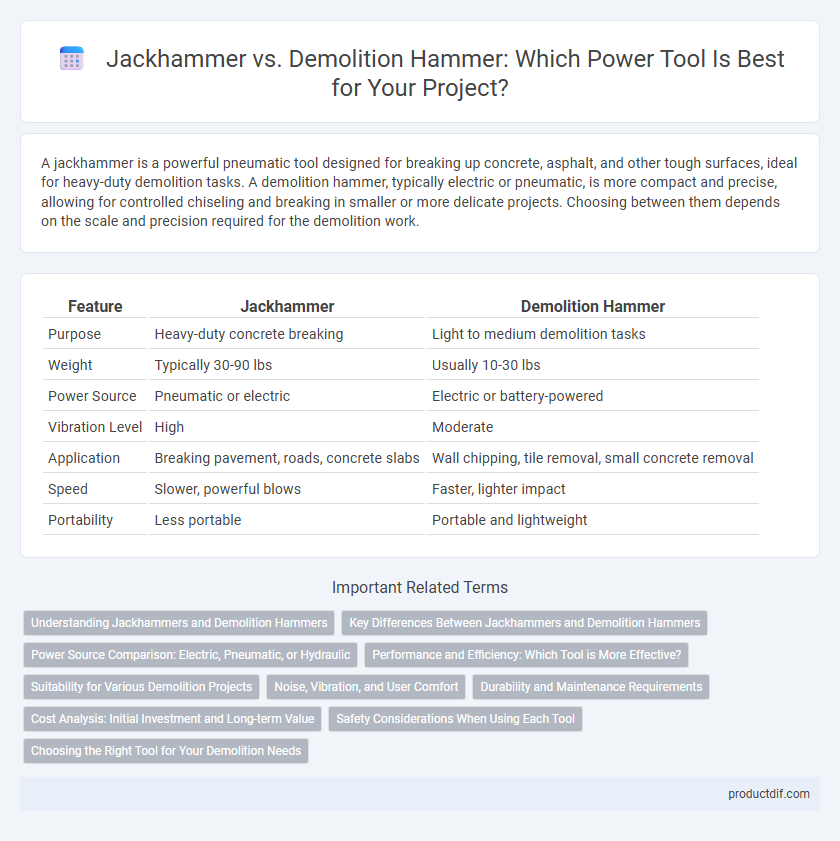

A jackhammer is a powerful pneumatic tool designed for breaking up concrete, asphalt, and other tough surfaces, ideal for heavy-duty demolition tasks. A demolition hammer, typically electric or pneumatic, is more compact and precise, allowing for controlled chiseling and breaking in smaller or more delicate projects. Choosing between them depends on the scale and precision required for the demolition work.

Table of Comparison

| Feature | Jackhammer | Demolition Hammer |

|---|---|---|

| Purpose | Heavy-duty concrete breaking | Light to medium demolition tasks |

| Weight | Typically 30-90 lbs | Usually 10-30 lbs |

| Power Source | Pneumatic or electric | Electric or battery-powered |

| Vibration Level | High | Moderate |

| Application | Breaking pavement, roads, concrete slabs | Wall chipping, tile removal, small concrete removal |

| Speed | Slower, powerful blows | Faster, lighter impact |

| Portability | Less portable | Portable and lightweight |

Understanding Jackhammers and Demolition Hammers

Jackhammers and demolition hammers are powerful tools designed for breaking concrete, asphalt, and hard surfaces, but their applications and mechanisms differ significantly. Jackhammers use a pneumatic or electric hammering action combined with a chisel bit to deliver rapid, forceful impacts suitable for large-scale demolition work. Demolition hammers, often lighter and electric-powered, provide more controlled and precise hammering ideal for smaller projects or detail work where maneuverability and efficiency are key.

Key Differences Between Jackhammers and Demolition Hammers

Jackhammers deliver powerful percussive force for breaking concrete and asphalt, making them ideal for heavy-duty excavation and roadwork, while demolition hammers offer more precise control suited for smaller-scale concrete removal and chiseling tasks. Jackhammers typically operate using pneumatic or hydraulic systems, generating higher impact energy compared to electric-powered demolition hammers designed for versatility and ease of use in confined spaces. The key differences lie in their weight, impact energy, and specific applications, with jackhammers emphasizing brute force and demolition hammers prioritizing maneuverability and detail work.

Power Source Comparison: Electric, Pneumatic, or Hydraulic

Jackhammers and demolition hammers differ significantly in their power sources, impacting performance and suitability for various tasks. Electric models offer portability and ease of use for light to medium jobs, while pneumatic jackhammers, powered by compressed air, deliver higher impact force ideal for heavy-duty demolition. Hydraulic demolition hammers provide superior power and control, making them the preferred choice for industrial applications requiring maximum impact and durability.

Performance and Efficiency: Which Tool is More Effective?

Jackhammers deliver high-impact power ideal for heavy-duty concrete breaking, making them highly effective in large-scale demolition projects requiring speed and force. Demolition hammers, while less powerful, offer greater precision and control for detailed chiseling and smaller tasks, enhancing efficiency in confined spaces. Performance depends on project scale: jackhammers excel in breaking tough materials quickly, whereas demolition hammers maximize efficiency in tasks needing accuracy and maneuverability.

Suitability for Various Demolition Projects

Jackhammers excel in heavy-duty demolition tasks such as breaking concrete slabs, asphalt, and large masonry where brute force is required. Demolition hammers offer greater precision and control, making them ideal for medium-scale projects like removing tiles, chiseling smaller concrete sections, and detailed renovation work. Selecting between a jackhammer and a demolition hammer depends on the project size, material hardness, and the need for accuracy versus raw power.

Noise, Vibration, and User Comfort

Jackhammers typically generate higher noise levels and more intense vibrations compared to demolition hammers, impacting user comfort during extended use. Demolition hammers are engineered with advanced vibration-dampening technology and noise reduction features, making them preferable for precision tasks and reducing operator fatigue. Selecting a demolition hammer can significantly enhance comfort and control, especially in indoor or noise-sensitive environments.

Durability and Maintenance Requirements

Jackhammers typically offer greater durability due to their robust construction designed for heavy-duty use in large-scale demolition projects. Demolition hammers, while still durable, often have more intricate components that require frequent maintenance to ensure optimal performance. Regular lubrication and timely parts replacement are essential to extend the lifespan of both tools, with jackhammers generally demanding less frequent maintenance compared to demolition hammers.

Cost Analysis: Initial Investment and Long-term Value

Jackhammers typically have a lower initial investment cost, ranging from $800 to $1,500, making them suitable for large-scale demolition projects with frequent heavy use. Demolition hammers, priced between $300 and $700, offer greater precision and versatility for smaller or medium tasks, resulting in lower maintenance and operational costs over time. Long-term value depends on project scale, with jackhammers providing durability for extensive work while demolition hammers deliver cost-effective performance for less intensive jobs.

Safety Considerations When Using Each Tool

Jackhammers require stringent safety measures due to their high vibration and noise levels, making the use of vibration-dampening gloves, ear protection, and steel-toed boots essential. Demolition hammers, while generally lighter and easier to control, still necessitate eye protection and dust masks to prevent inhalation of debris and minimize injury risks. Proper training and adherence to manufacturer guidelines significantly reduce hazards associated with both tools, ensuring safer operation on construction sites.

Choosing the Right Tool for Your Demolition Needs

A jackhammer delivers high-impact percussive force ideal for breaking concrete and asphalt in large-scale demolition projects, while a demolition hammer offers more precision and control for smaller, detailed tasks such as tile removal or chipping brick. Selecting the right tool depends on the scale and nature of your demolition needs, with jackhammers suited for heavy-duty breaking and demolition hammers optimized for accuracy and versatility in confined spaces. Consider factors like power, weight, and bit compatibility to ensure efficient and safe operation in your specific application.

Jackhammer vs Demolition Hammer Infographic

productdif.com

productdif.com