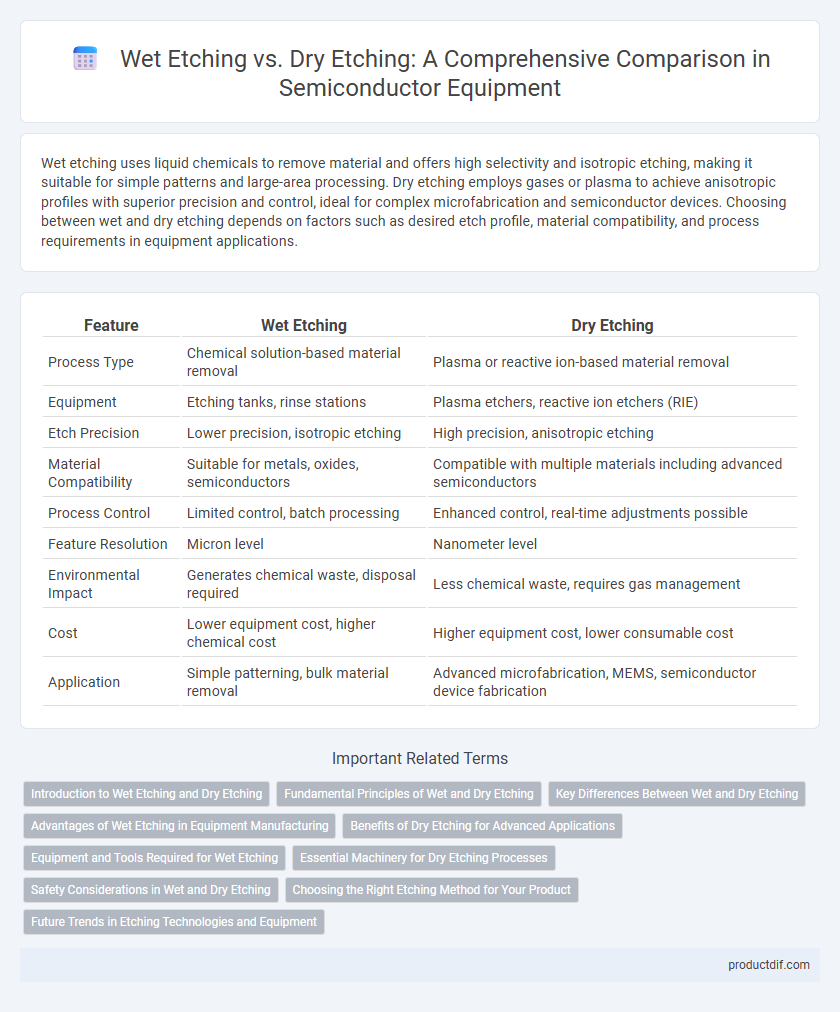

Wet etching uses liquid chemicals to remove material and offers high selectivity and isotropic etching, making it suitable for simple patterns and large-area processing. Dry etching employs gases or plasma to achieve anisotropic profiles with superior precision and control, ideal for complex microfabrication and semiconductor devices. Choosing between wet and dry etching depends on factors such as desired etch profile, material compatibility, and process requirements in equipment applications.

Table of Comparison

| Feature | Wet Etching | Dry Etching |

|---|---|---|

| Process Type | Chemical solution-based material removal | Plasma or reactive ion-based material removal |

| Equipment | Etching tanks, rinse stations | Plasma etchers, reactive ion etchers (RIE) |

| Etch Precision | Lower precision, isotropic etching | High precision, anisotropic etching |

| Material Compatibility | Suitable for metals, oxides, semiconductors | Compatible with multiple materials including advanced semiconductors |

| Process Control | Limited control, batch processing | Enhanced control, real-time adjustments possible |

| Feature Resolution | Micron level | Nanometer level |

| Environmental Impact | Generates chemical waste, disposal required | Less chemical waste, requires gas management |

| Cost | Lower equipment cost, higher chemical cost | Higher equipment cost, lower consumable cost |

| Application | Simple patterning, bulk material removal | Advanced microfabrication, MEMS, semiconductor device fabrication |

Introduction to Wet Etching and Dry Etching

Wet etching involves the use of liquid chemical solutions to selectively remove material from a substrate, commonly utilized for isotropic etching in semiconductor fabrication. Dry etching employs plasma or reactive gases to achieve anisotropic material removal with higher precision and control, essential for complex microfabrication processes. Both techniques play critical roles in equipment design for integrated circuit manufacturing, balancing aspects like etch rate, selectivity, and pattern fidelity.

Fundamental Principles of Wet and Dry Etching

Wet etching utilizes liquid chemical solutions to selectively dissolve material from the substrate, relying on isotropic chemical reactions that can affect both horizontal and vertical surfaces. Dry etching involves plasma or reactive ion processes to remove materials through physical sputtering or chemical reactions, enabling anisotropic etching with higher precision and directional control. Fundamental principles distinguish wet etching's reliance on chemical solubility and diffusivity from dry etching's dependence on ion bombardment energy and reactive species in a plasma environment.

Key Differences Between Wet and Dry Etching

Wet etching uses liquid chemical solutions to remove material, offering high selectivity and isotropic etching, while dry etching employs gases or plasma for anisotropic etching and finer pattern control. Dry etching processes, such as reactive ion etching (RIE), provide superior directionality and precision essential for microfabrication in semiconductor manufacturing. Wet etching is generally faster and simpler but less suitable for complex, high-resolution structures compared to dry etching techniques.

Advantages of Wet Etching in Equipment Manufacturing

Wet etching offers superior material selectivity and uniformity, making it ideal for precise pattern transfer in semiconductor equipment manufacturing. The process leverages liquid chemicals to remove targeted materials efficiently, reducing equipment complexity and operational costs. Its compatibility with a wide range of materials and ability to achieve isotropic etching enhance manufacturing flexibility and product quality.

Benefits of Dry Etching for Advanced Applications

Dry etching offers precise anisotropic etching capabilities essential for advanced semiconductor fabrication, enabling the creation of high-resolution micro- and nanoscale patterns. Its compatibility with plasma-based techniques allows selective material removal with minimal substrate damage, crucial for delicate device architectures such as MEMS and integrated circuits. Enhanced control over etch depth and uniformity improves process repeatability, reducing defects and increasing overall yield in complex manufacturing environments.

Equipment and Tools Required for Wet Etching

Wet etching requires specialized equipment such as chemical-resistant tanks, baths, and liquid handling systems to safely contain and process etchants like hydrofluoric acid or nitric acid. Precision temperature control units and agitation systems are essential to achieve uniform etch rates and maintain process consistency. Proper waste management and fume extraction tools are critical for handling hazardous chemicals and ensuring operator safety during the wet etching process.

Essential Machinery for Dry Etching Processes

Essential machinery for dry etching processes includes inductively coupled plasma (ICP) reactors, reactive ion etching (RIE) systems, and deep reactive ion etching (DRIE) equipment. These systems use plasma sources to generate reactive ions that precisely remove material, enabling high-resolution patterning with superior anisotropy compared to wet etching. Advanced control over gas flow, pressure, and radio frequency power in dry etching machines ensures uniform etch rates and feature profiles critical for semiconductor fabrication.

Safety Considerations in Wet and Dry Etching

Wet etching involves hazardous chemicals such as acids and bases, requiring stringent handling protocols and proper ventilation to minimize exposure to corrosive fumes and chemical burns. Dry etching uses reactive gases and plasma, demanding advanced safety measures like gas leak detection systems and effective exhaust setups to prevent inhalation of toxic byproducts and avoid electrical hazards. Both methods necessitate comprehensive personal protective equipment (PPE) and rigorous training to ensure operator safety during semiconductor fabrication processes.

Choosing the Right Etching Method for Your Product

Selecting the right etching method depends on the material's properties and the desired precision; wet etching offers high selectivity and simplicity for isotropic removal, ideal for metals and oxides. Dry etching provides anisotropic profiles with superior control, suitable for advanced semiconductor devices requiring precise pattern transfer. Assessing factors like etch rate, surface damage, and feature resolution ensures optimal process integration and product performance.

Future Trends in Etching Technologies and Equipment

Emerging etching technologies emphasize atomic layer etching (ALE) to achieve unprecedented precision and minimal damage in semiconductor fabrication. Integration of AI-driven process control systems enhances real-time monitoring and optimization, improving yield and efficiency in both wet and dry etching equipment. Future equipment developments focus on eco-friendly plasma sources and chemical solutions to reduce environmental impact while maintaining high throughput in advanced node manufacturing.

Wet etching vs Dry etching Infographic

productdif.com

productdif.com