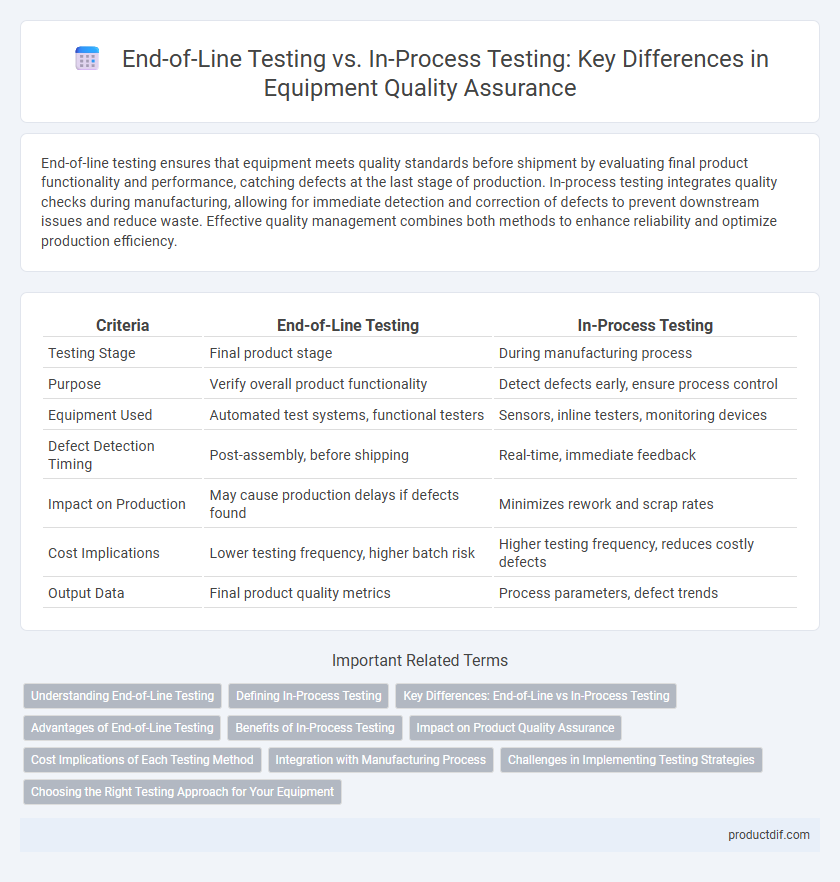

End-of-line testing ensures that equipment meets quality standards before shipment by evaluating final product functionality and performance, catching defects at the last stage of production. In-process testing integrates quality checks during manufacturing, allowing for immediate detection and correction of defects to prevent downstream issues and reduce waste. Effective quality management combines both methods to enhance reliability and optimize production efficiency.

Table of Comparison

| Criteria | End-of-Line Testing | In-Process Testing |

|---|---|---|

| Testing Stage | Final product stage | During manufacturing process |

| Purpose | Verify overall product functionality | Detect defects early, ensure process control |

| Equipment Used | Automated test systems, functional testers | Sensors, inline testers, monitoring devices |

| Defect Detection Timing | Post-assembly, before shipping | Real-time, immediate feedback |

| Impact on Production | May cause production delays if defects found | Minimizes rework and scrap rates |

| Cost Implications | Lower testing frequency, higher batch risk | Higher testing frequency, reduces costly defects |

| Output Data | Final product quality metrics | Process parameters, defect trends |

Understanding End-of-Line Testing

End-of-line testing evaluates the final product to ensure it meets all quality and functional specifications before shipment, identifying defects that escaped earlier processes. It involves comprehensive checks such as electrical performance, mechanical integrity, and software functionality, guaranteeing compliance with industry standards. This testing phase is critical for minimizing returns and enhancing customer satisfaction by certifying each unit's readiness for market.

Defining In-Process Testing

In-process testing involves evaluating equipment and components at critical stages during the manufacturing workflow to ensure quality and functionality before final assembly. This method enables early detection of defects, reducing costly rework and improving overall production efficiency. By continuously monitoring parameters such as dimension accuracy, electrical performance, and system functionality, in-process testing maintains consistent product standards throughout production.

Key Differences: End-of-Line vs In-Process Testing

End-of-line testing occurs after the manufacturing process is complete, ensuring product functionality and compliance before shipment, while in-process testing happens during production to detect defects early and maintain quality control. End-of-line testing typically involves comprehensive final inspections and system validations, whereas in-process testing focuses on monitoring specific parameters and process variables in real-time. The key difference lies in timing and purpose: end-of-line testing validates finished products, whereas in-process testing prevents defects by enabling immediate corrections during manufacturing.

Advantages of End-of-Line Testing

End-of-line testing ensures comprehensive quality control by verifying the complete functionality of equipment before it reaches the customer, significantly reducing the risk of defective products. This testing method allows for the identification and correction of faults in the final assembly, enhancing overall product reliability and customer satisfaction. It also supports compliance with industry standards by providing documented evidence of performance and safety before equipment deployment.

Benefits of In-Process Testing

In-process testing enhances real-time defect detection, reducing the risk of producing faulty equipment and minimizing costly rework or recalls. Continuous monitoring during production streamlines quality control by allowing immediate adjustments, improving overall manufacturing efficiency and yield. This proactive approach ensures consistent equipment performance and compliance with industry standards.

Impact on Product Quality Assurance

End-of-line testing provides a final verification step ensuring that products meet quality standards before shipment, catching defects missed during production. In-process testing allows for real-time detection of issues, minimizing the risk of defects propagating through the manufacturing process and reducing rework costs. Implementing both testing strategies enhances product quality assurance by combining comprehensive defect identification with timely corrective actions.

Cost Implications of Each Testing Method

End-of-Line Testing typically incurs higher costs due to complete assembly completion before testing, leading to potential waste if defects are found late. In-Process Testing reduces rework expenses by identifying defects early during production, improving yield and lowering scrap rates. Choosing between these methods depends on balancing upfront testing investment against potential cost savings from early defect detection.

Integration with Manufacturing Process

End-of-line testing typically integrates at the final stage of production, ensuring that each unit meets quality standards before shipment. In-process testing is embedded throughout the manufacturing workflow, enabling real-time defect detection and process adjustments to minimize scrap rates. Seamless integration of both testing methods can optimize product quality while maintaining efficient production cycles.

Challenges in Implementing Testing Strategies

End-of-line testing faces challenges such as limited defect detection granularity and higher costs due to testing entire assemblies, often leading to delayed identification of faults. In-process testing demands integration with manufacturing workflows, requiring sophisticated sensor network installation and real-time data analysis, which can complicate production and increase downtime. Balancing the trade-offs between comprehensive final inspections and continuous in-process monitoring remains a critical challenge in deploying effective testing strategies.

Choosing the Right Testing Approach for Your Equipment

End-of-line testing ensures final product quality by verifying performance and safety after manufacturing but may not detect defects occurring earlier in the process. In-process testing allows real-time monitoring and immediate correction, reducing waste and improving efficiency by identifying issues during production. Selecting the right testing approach depends on factors such as production volume, equipment complexity, defect criticality, and cost constraints.

End-of-Line Testing vs In-Process Testing Infographic

productdif.com

productdif.com