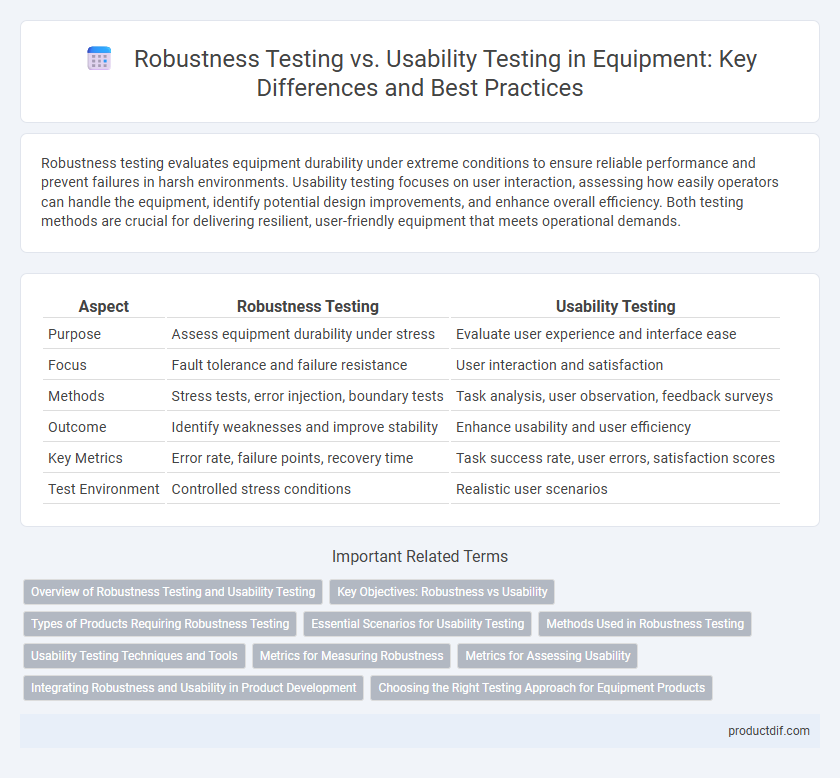

Robustness testing evaluates equipment durability under extreme conditions to ensure reliable performance and prevent failures in harsh environments. Usability testing focuses on user interaction, assessing how easily operators can handle the equipment, identify potential design improvements, and enhance overall efficiency. Both testing methods are crucial for delivering resilient, user-friendly equipment that meets operational demands.

Table of Comparison

| Aspect | Robustness Testing | Usability Testing |

|---|---|---|

| Purpose | Assess equipment durability under stress | Evaluate user experience and interface ease |

| Focus | Fault tolerance and failure resistance | User interaction and satisfaction |

| Methods | Stress tests, error injection, boundary tests | Task analysis, user observation, feedback surveys |

| Outcome | Identify weaknesses and improve stability | Enhance usability and user efficiency |

| Key Metrics | Error rate, failure points, recovery time | Task success rate, user errors, satisfaction scores |

| Test Environment | Controlled stress conditions | Realistic user scenarios |

Overview of Robustness Testing and Usability Testing

Robustness testing evaluates equipment's ability to perform under extreme conditions, identifying vulnerabilities and ensuring reliability during unexpected stress or failures. Usability testing focuses on how effectively and efficiently end-users can operate equipment, assessing intuitive design, user satisfaction, and error rates. Together, these tests optimize product durability and user experience by balancing technical resilience with practical functionality.

Key Objectives: Robustness vs Usability

Robustness testing aims to evaluate equipment performance under extreme conditions and unexpected inputs to ensure reliability and fault tolerance. Usability testing focuses on assessing how easily users can operate the equipment, emphasizing intuitive design and user experience. The key objective of robustness is to verify durability and error handling, while usability prioritizes user satisfaction and efficiency.

Types of Products Requiring Robustness Testing

Robustness testing is essential for equipment used in harsh environments such as industrial machinery, automotive components, and aerospace systems, where durability and resistance to extreme conditions are critical. Usability testing applies primarily to consumer electronics, medical devices, and software-driven tools, focusing on user interaction and ease of operation. Products requiring robustness testing typically undergo rigorous assessments for vibration, temperature, shock, and corrosion resistance to ensure long-term reliability.

Essential Scenarios for Usability Testing

Usability testing targets essential scenarios that mimic real-world equipment operation to ensure intuitive user interaction and efficiency under typical conditions. Robustness testing evaluates equipment durability against extreme or unexpected stressors, such as power fluctuations or physical impact, to guarantee reliability. Emphasizing essential scenarios in usability testing drives product refinement by identifying critical user challenges and enhancing functional design.

Methods Used in Robustness Testing

Robustness testing methods for equipment primarily involve stress testing, fault injection, and boundary value analysis to ensure the system operates under extreme or unexpected conditions. These techniques simulate hardware failures, power fluctuations, and environmental stresses to evaluate the equipment's durability and error-handling capabilities. Such testing contrasts with usability evaluations, which focus on user interaction and interface intuitiveness rather than operational resilience.

Usability Testing Techniques and Tools

Usability testing techniques for equipment include heuristic evaluation, cognitive walkthroughs, and task analysis to ensure intuitive user interaction and minimize errors. Common tools used in usability testing comprise eye-tracking devices, usability labs with video monitoring, and software for recording user behavior and feedback. These methods and tools provide critical insights into user experience, facilitating enhancements in equipment design and functionality.

Metrics for Measuring Robustness

Metrics for measuring robustness in equipment include failure rate under stress conditions, mean time between failures (MTBF), and recovery time after faults, which collectively assess durability and reliability in harsh environments. Stress tests quantify equipment performance at extreme temperatures, vibrations, and loads to ensure operational stability. These robustness metrics differ significantly from usability testing metrics, which prioritize user interaction efficiency, error rates, and satisfaction scores.

Metrics for Assessing Usability

Usability testing metrics primarily include task success rate, error rate, and time on task, which evaluate how effectively and efficiently users can operate equipment. Robustness testing focuses on metrics such as mean time between failures (MTBF), failure rate, and recovery time to assess equipment durability under stress conditions. Combining these metrics ensures a comprehensive evaluation of both equipment resilience and user experience.

Integrating Robustness and Usability in Product Development

Integrating robustness and usability in product development ensures equipment performs reliably under stress while remaining user-friendly, reducing failure rates and increasing customer satisfaction. Robustness testing simulates harsh conditions and prolonged use to identify weaknesses, whereas usability testing evaluates ease of operation and user interaction. Combining these approaches early in design enhances product durability and optimizes user experience, leading to competitive advantage and reduced maintenance costs.

Choosing the Right Testing Approach for Equipment Products

Robustness testing evaluates equipment's ability to withstand extreme conditions and unexpected stress, ensuring durability and long-term reliability in various environments. Usability testing focuses on how easily end-users can operate the equipment, emphasizing intuitive design, safety, and ergonomic features to enhance user experience. Selecting the right testing approach depends on product goals, where robustness testing suits rugged industrial tools and usability testing is critical for consumer electronics requiring user-friendly interfaces.

Robustness testing vs Usability testing Infographic

productdif.com

productdif.com