A paint booth uses liquid paint sprayed onto surfaces and requires controlled airflow to prevent contamination and ensure an even finish, while a powder coating booth applies dry powder electrostatically and cures it under heat for a durable, uniform coating. Paint booths demand extensive ventilation systems to manage overspray and fumes, whereas powder coating booths recycle excess powder, making them more environmentally friendly and cost-effective. Choosing between the two depends on the desired finish, material compatibility, and production requirements.

Table of Comparison

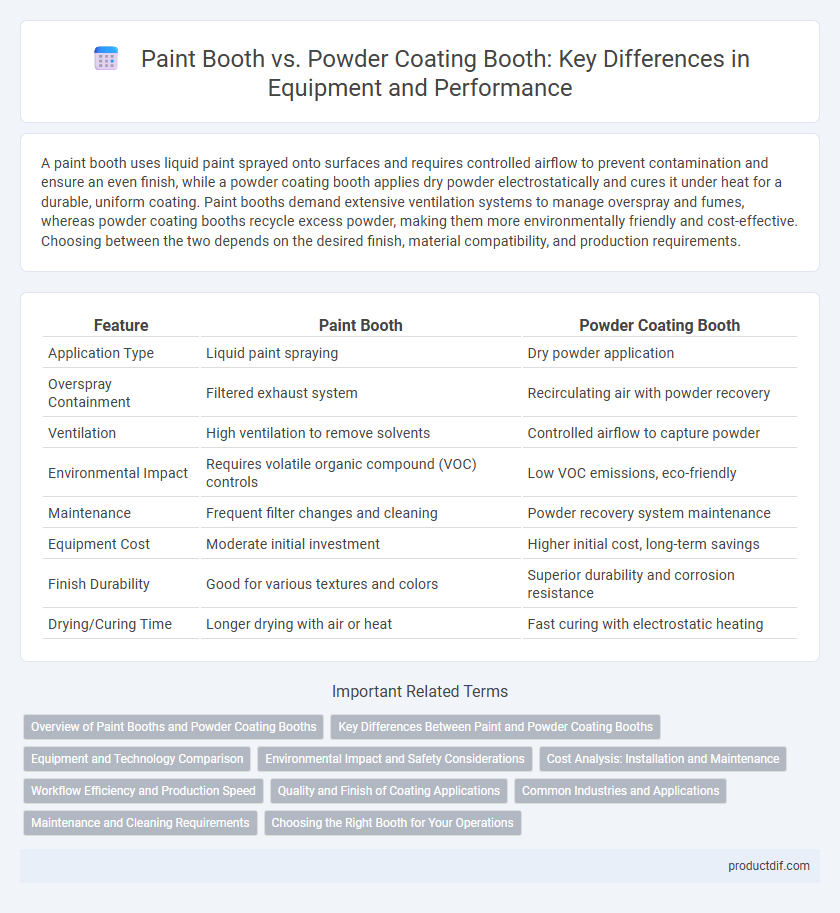

| Feature | Paint Booth | Powder Coating Booth |

|---|---|---|

| Application Type | Liquid paint spraying | Dry powder application |

| Overspray Containment | Filtered exhaust system | Recirculating air with powder recovery |

| Ventilation | High ventilation to remove solvents | Controlled airflow to capture powder |

| Environmental Impact | Requires volatile organic compound (VOC) controls | Low VOC emissions, eco-friendly |

| Maintenance | Frequent filter changes and cleaning | Powder recovery system maintenance |

| Equipment Cost | Moderate initial investment | Higher initial cost, long-term savings |

| Finish Durability | Good for various textures and colors | Superior durability and corrosion resistance |

| Drying/Curing Time | Longer drying with air or heat | Fast curing with electrostatic heating |

Overview of Paint Booths and Powder Coating Booths

Paint booths are ventilated enclosures designed for applying liquid paint, featuring controlled airflow and filtration systems to minimize overspray and ensure a smooth finish. Powder coating booths use electrostatic spray guns to apply dry powder, followed by curing in an oven to create a durable, high-quality coating. Both types of booths prioritize environmental controls, worker safety, and compliance with industry standards such as OSHA and EPA regulations.

Key Differences Between Paint and Powder Coating Booths

Paint booths use liquid coatings applied with spray guns requiring controlled airflow and solvent ventilation systems, while powder coating booths utilize electrostatically charged powder particles and require booths with specialized filtration for overspray recovery. Paint booths often need explosion-proof lighting and ventilation due to flammable solvents, whereas powder coating booths emphasize containment of dry powder and efficient powder reclamation systems. The curing process also differs, with paint booths usually relying on air drying or ovens and powder coating booths requiring heated curing ovens to fuse the powder into a durable finish.

Equipment and Technology Comparison

Paint booths utilize liquid paint spray systems requiring extensive ventilation and filtration equipment to manage volatile organic compounds, while powder coating booths employ electrostatic spray technology with dry powder particles, necessitating specialized recovery and recycling systems for overspray. Advanced paint booths integrate robotics and infrared curing equipment to enhance finish quality and reduce drying time, whereas powder coating booths rely on precise electrostatic guns and infrared or convection curing ovens for consistent and durable coatings. Equipment choice impacts operational costs, environmental compliance, and maintenance, making technology integration a critical factor in selecting the optimal booth for specific industrial applications.

Environmental Impact and Safety Considerations

Paint booths emit volatile organic compounds (VOCs) that contribute to air pollution and require extensive ventilation and filtration systems to protect worker health and comply with environmental regulations. Powder coating booths produce minimal VOC emissions, making them more environmentally friendly and reducing the need for complex air handling systems. Safety considerations in paint booths include fire hazards from flammable solvents, while powder coating booths minimize these risks due to the use of dry powder coatings and less combustible materials.

Cost Analysis: Installation and Maintenance

Paint booths typically involve higher installation costs due to complex ventilation and fire suppression systems required for handling volatile organic compounds (VOCs). Powder coating booths often have lower maintenance expenses as they do not require solvent recovery systems and generate less hazardous waste. Over time, powder coating booths offer cost savings in both energy consumption and environmental compliance compared to traditional paint booths.

Workflow Efficiency and Production Speed

Paint booths typically require longer drying times and multiple application layers, which can slow down workflow efficiency compared to powder coating booths. Powder coating booths offer faster curing processes through electrostatic application and oven curing, significantly enhancing production speed and throughput. Industries prioritize powder coating booths for high-volume operations due to their reduced cycle times and superior process consistency.

Quality and Finish of Coating Applications

Paint booths provide superior control over environmental factors such as dust and humidity, resulting in smooth, even finishes ideal for detailed and high-gloss coatings. Powder coating booths excel in achieving extremely durable, uniform coatings with enhanced resistance to chipping, scratching, and corrosion, making them perfect for heavy-duty applications. The choice between paint and powder coating booths significantly impacts the final quality and finish, with powder booths offering a more resilient surface and paint booths delivering finer detail and color depth.

Common Industries and Applications

Paint booths are widely used in automotive, aerospace, and furniture industries for applying liquid paint finishes, providing controlled environments that prevent contamination and ensure uniform coating. Powder coating booths are prevalent in manufacturing sectors such as metal fabrication, appliances, and architectural components, offering a durable, electrostatically applied finish with superior resistance to corrosion and wear. Both types of booths cater to specific application needs, with paint booths favored for aesthetic and color customization and powder coating booths chosen for high-durability and environmental compliance.

Maintenance and Cleaning Requirements

Paint booths require frequent cleaning to prevent paint buildup and ensure proper airflow, often involving solvent use and filter replacements. Powder coating booths demand less frequent cleaning since powder overspray can be reclaimed, but they require regular removal of powder residue to avoid contamination and maintain equipment efficiency. Both types benefit from scheduled inspections to preserve optimal performance and comply with safety standards.

Choosing the Right Booth for Your Operations

Paint booths offer versatile color application with liquid coatings, ideal for projects requiring smooth, glossy finishes and easy color changes, while powder coating booths provide durable, environmentally friendly finishes with superior corrosion resistance, making them suitable for high-wear industrial parts. Consider factors such as booth ventilation, curing methods, production volume, and environmental compliance when selecting between paint and powder coating booths. Matching the booth type to your product specifications and operational workflow maximizes efficiency and finish quality.

Paint booth vs Powder coating booth Infographic

productdif.com

productdif.com