Wave soldering uses a continuous wave of molten solder to quickly join components to printed circuit boards, ideal for through-hole technology and high-volume production. Reflow soldering involves applying solder paste and heating the board to melt the solder, making it suitable for surface-mount devices with precise temperature control. Equipment choice depends on component type, board design, and production scale, with reflow offering better control for complex assemblies and wave soldering providing faster throughput for simpler layouts.

Table of Comparison

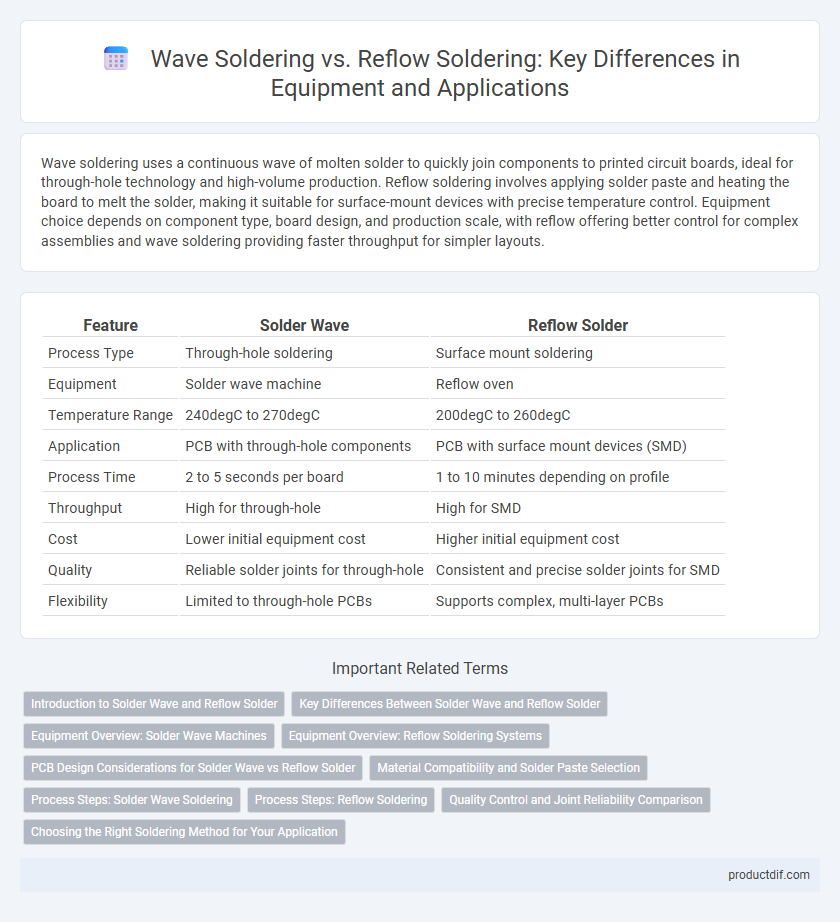

| Feature | Solder Wave | Reflow Solder |

|---|---|---|

| Process Type | Through-hole soldering | Surface mount soldering |

| Equipment | Solder wave machine | Reflow oven |

| Temperature Range | 240degC to 270degC | 200degC to 260degC |

| Application | PCB with through-hole components | PCB with surface mount devices (SMD) |

| Process Time | 2 to 5 seconds per board | 1 to 10 minutes depending on profile |

| Throughput | High for through-hole | High for SMD |

| Cost | Lower initial equipment cost | Higher initial equipment cost |

| Quality | Reliable solder joints for through-hole | Consistent and precise solder joints for SMD |

| Flexibility | Limited to through-hole PCBs | Supports complex, multi-layer PCBs |

Introduction to Solder Wave and Reflow Solder

Solder wave and reflow solder are essential equipment processes in electronics manufacturing for attaching components to printed circuit boards (PCBs). Solder wave involves passing the PCB over a wave of molten solder to create uniform solder joints, ideal for through-hole components, while reflow solder uses heated air or infrared to melt solder paste applied to surface-mount devices (SMDs). Both methods ensure reliable electrical connections, with reflow solder preferred for complex, high-density assemblies and solder wave for robust, mechanical stability in larger parts.

Key Differences Between Solder Wave and Reflow Solder

Solder wave soldering uses a continuous wave of molten solder to join components, primarily on through-hole printed circuit boards (PCBs), while reflow soldering involves applying solder paste and heating the entire board in an oven to bond surface-mounted devices (SMDs). Wave soldering is typically faster for large volumes of through-hole components but less precise compared to reflow soldering, which provides superior control and uniformity for complex and densely packed SMD assemblies. The choice between wave and reflow soldering impacts solder joint quality, process efficiency, and suitability for different PCB types and component placements.

Equipment Overview: Solder Wave Machines

Solder wave machines are specialized equipment designed for through-hole PCB assembly, providing a continuous wave of molten solder to ensure reliable joint formation. These machines excel in high-volume production environments, offering precise temperature control and adjustable conveyor speeds to accommodate various PCB sizes and component densities. Unlike reflow soldering which uses controlled heat profiles for surface-mount components, wave soldering equipment is distinct in applying wave soldering technology for bulk, efficient solder coverage on complex boards with multiple through-hole components.

Equipment Overview: Reflow Soldering Systems

Reflow soldering systems utilize precise temperature-controlled ovens to melt solder paste and create reliable electronic connections on printed circuit boards, ensuring high throughput and consistent quality in mass production. These systems feature advanced conveyor belts, multi-zone heating profiles, and nitrogen atmosphere options to minimize oxidation and improve solder joint integrity. Compared to wave soldering, reflow equipment supports surface mount technology (SMT) components with better thermal control and less mechanical stress.

PCB Design Considerations for Solder Wave vs Reflow Solder

PCB design considerations for solder wave versus reflow solder focus on pad configuration and component placement to ensure optimal thermal profiles. Wave soldering requires through-hole pad layouts with sufficient clearance to prevent solder bridging, while reflow soldering suits surface-mount device (SMD) pads designed for precise solder paste application and thermal mass distribution. Effective thermal management in PCB design is critical, where thicker copper layers and thermal relief pads help achieve uniform heat distribution for both soldering methods.

Material Compatibility and Solder Paste Selection

Wave soldering excels in compatibility with through-hole components and traditional PCBs using flux-cored solder wire, while reflow soldering caters to surface-mount devices (SMD) requiring precise solder paste formulations. Solder paste selection for reflow involves temperature profiles and alloy compositions tailored to prevent damage on sensitive materials like plastics and multilayer boards. Wave soldering demands less complex paste but careful flux selection to avoid board contamination and ensure strong metallurgical bonds on diverse component leads.

Process Steps: Solder Wave Soldering

Wave soldering involves passing PCBs over a wave of molten solder where the underside of the board contacts the solder, creating reliable joints for through-hole components. The primary steps include flux application, preheating to activate the flux and reduce thermal shock, exposure to the solder wave, and cooling to solidify joints. This continuous process is efficient for high-volume production with consistent solder quality on complex PCBs.

Process Steps: Reflow Soldering

Reflow soldering involves applying solder paste to PCB pads before placing surface-mount components, followed by controlled heating in a reflow oven to melt the solder. The process consists of preheating, soaking, reflow, and cooling stages to ensure proper solder joint formation and component adhesion. Precise temperature profiling in the reflow oven is critical to prevent thermal damage and achieve optimal electrical connections.

Quality Control and Joint Reliability Comparison

Solder wave provides consistent, high-speed soldering ideal for through-hole components, ensuring robust joint reliability with minimal voids and enhanced mechanical strength. Reflow soldering offers superior quality control through precise temperature profiling and uniform solder paste melting, optimizing joint consistency for surface-mount devices. Wave soldering excels in bulk processing with durable joints, while reflow soldering delivers enhanced control over solder quality, reducing defects like tombstoning and bridging in complex PCB assemblies.

Choosing the Right Soldering Method for Your Application

Selecting the right soldering method depends on the component size, production volume, and thermal sensitivity. Wave soldering excels in through-hole component assembly with high throughput, while reflow soldering is ideal for precise surface-mount technology (SMT) applications and complex circuit boards. Evaluating factors like solder joint quality, process compatibility, and cost efficiency ensures optimal results for your electronics manufacturing process.

Solder wave vs Reflow solder Infographic

productdif.com

productdif.com