Servo motors provide precise control and high torque at varying speeds, making them ideal for applications requiring dynamic response and accuracy. Stepper motors offer reliable, open-loop control and simplicity, excelling in tasks with consistent speed and position without feedback systems. Choosing between servo and stepper motors depends on the balance of performance needs, cost considerations, and complexity of the pet equipment's motion requirements.

Table of Comparison

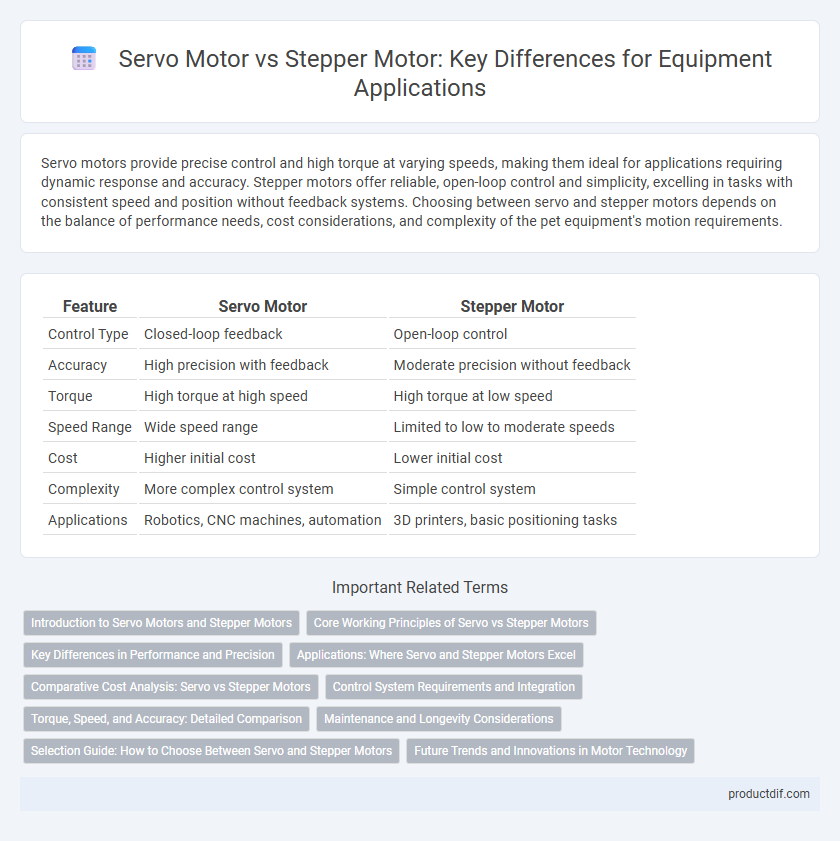

| Feature | Servo Motor | Stepper Motor |

|---|---|---|

| Control Type | Closed-loop feedback | Open-loop control |

| Accuracy | High precision with feedback | Moderate precision without feedback |

| Torque | High torque at high speed | High torque at low speed |

| Speed Range | Wide speed range | Limited to low to moderate speeds |

| Cost | Higher initial cost | Lower initial cost |

| Complexity | More complex control system | Simple control system |

| Applications | Robotics, CNC machines, automation | 3D printers, basic positioning tasks |

Introduction to Servo Motors and Stepper Motors

Servo motors offer precise control of angular or linear position, velocity, and acceleration through feedback mechanisms, making them ideal for applications requiring high accuracy and dynamic response. Stepper motors operate by dividing a full rotation into equal steps, enabling controlled movement without feedback systems, which suits simpler positioning tasks with moderate precision. Both motors serve critical roles in automation and robotics, with choice depending on torque requirements, speed, and control complexity.

Core Working Principles of Servo vs Stepper Motors

Servo motors operate using a feedback system with an encoder or resolver to continuously monitor position, velocity, and torque, enabling precise control and smooth motion. Stepper motors move in discrete steps controlled by electrical pulses, rotating incrementally without feedback but with open-loop position management. The core difference lies in servo motors' closed-loop control for higher accuracy and dynamic response, versus stepper motors' simpler, cost-effective open-loop operation suited for applications requiring consistent step movement.

Key Differences in Performance and Precision

Servo motors deliver high torque and precise control with closed-loop feedback systems, enabling smooth acceleration and deceleration in dynamic applications. Stepper motors operate with open-loop control, providing precise positioning through incremental steps but often exhibit lower torque and potential vibration at high speeds. Servo motors excel in efficiency and accuracy for complex motion, while stepper motors are ideal for simple, cost-effective positioning tasks requiring moderate precision.

Applications: Where Servo and Stepper Motors Excel

Servo motors excel in high-precision applications such as robotics, CNC machinery, and automated manufacturing systems due to their closed-loop control and ability to provide accurate speed and position feedback. Stepper motors are ideal for open-loop control scenarios like 3D printers, small automation devices, and positioning systems where cost-effectiveness and simple speed control are essential. Both motors are widely used in industrial automation, but servo motors dominate tasks requiring dynamic speed changes and high torque, while stepper motors suit repetitive, low-speed operations.

Comparative Cost Analysis: Servo vs Stepper Motors

Servo motors generally involve higher initial costs than stepper motors due to complex components like encoders and advanced control systems. Stepper motors offer a cost-effective solution for applications requiring less precision and torque, benefiting from simpler design and cheaper manufacturing. Maintenance and energy consumption costs also tend to be lower for stepper motors, influencing the total cost of ownership in long-term operations.

Control System Requirements and Integration

Servo motors require closed-loop control systems with feedback devices such as encoders or resolvers to ensure precise position, speed, and torque control, making integration more complex and costly. Stepper motors operate with open-loop control systems, relying on discrete step pulses for positioning, which simplifies integration but may lead to missed steps under load. Choosing between these motors depends on the application's need for accuracy, complexity of the control system, and budget constraints.

Torque, Speed, and Accuracy: Detailed Comparison

Servo motors deliver higher torque and faster speeds due to closed-loop feedback systems, enabling precise control and efficient performance in dynamic applications. Stepper motors provide excellent accuracy through incremental movement but generally have lower torque and speed capabilities, making them ideal for applications requiring precise positioning at moderate performance levels. The choice depends on the application's demand for torque, speed, and accuracy, with servo motors favored for high-speed, high-torque tasks and stepper motors selected for cost-effective, reliable precision.

Maintenance and Longevity Considerations

Servo motors typically require less maintenance than stepper motors due to their closed-loop control systems that reduce mechanical wear and prevent overheating. Stepper motors often suffer from missed steps and overheating, leading to more frequent inspections and replacements. The longevity of servo motors generally surpasses stepper motors in industrial equipment, supported by advanced diagnostics and efficient cooling mechanisms.

Selection Guide: How to Choose Between Servo and Stepper Motors

Selecting between servo and stepper motors depends on precision, speed, and application requirements. Servo motors offer high torque and speed with closed-loop control for dynamic, precise positioning, ideal for robotics or CNC machinery. Stepper motors provide accurate open-loop control at lower cost and simpler maintenance, suited for applications with moderate torque and speed like 3D printers or automated camera systems.

Future Trends and Innovations in Motor Technology

Advancements in motor technology highlight increased integration of AI and IoT with servo and stepper motors for enhanced precision and adaptive control. Emerging materials and improved power electronics enable greater efficiency, higher torque density, and reduced heat generation in both motor types. Future trends emphasize smart motors capable of self-diagnostics and predictive maintenance, transforming industrial automation and robotics performance.

Servo motor vs Stepper motor Infographic

productdif.com

productdif.com