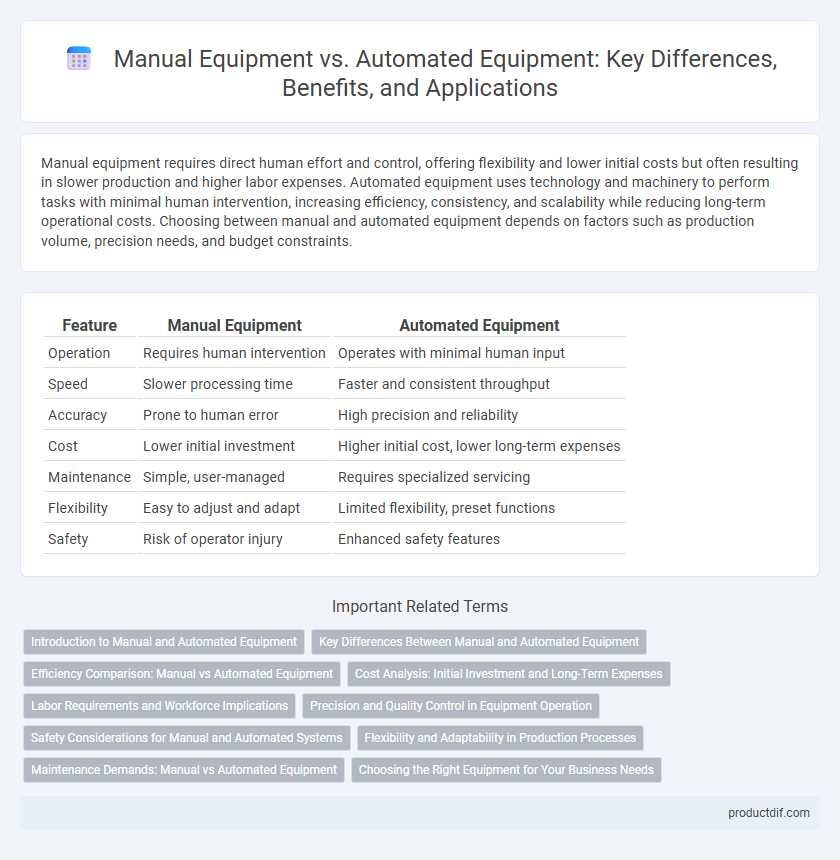

Manual equipment requires direct human effort and control, offering flexibility and lower initial costs but often resulting in slower production and higher labor expenses. Automated equipment uses technology and machinery to perform tasks with minimal human intervention, increasing efficiency, consistency, and scalability while reducing long-term operational costs. Choosing between manual and automated equipment depends on factors such as production volume, precision needs, and budget constraints.

Table of Comparison

| Feature | Manual Equipment | Automated Equipment |

|---|---|---|

| Operation | Requires human intervention | Operates with minimal human input |

| Speed | Slower processing time | Faster and consistent throughput |

| Accuracy | Prone to human error | High precision and reliability |

| Cost | Lower initial investment | Higher initial cost, lower long-term expenses |

| Maintenance | Simple, user-managed | Requires specialized servicing |

| Flexibility | Easy to adjust and adapt | Limited flexibility, preset functions |

| Safety | Risk of operator injury | Enhanced safety features |

Introduction to Manual and Automated Equipment

Manual equipment requires direct human operation, relying on physical effort and skill to perform tasks efficiently in various industries. Automated equipment utilizes advanced technology, including sensors, controllers, and software, to execute processes with minimal human intervention, enhancing precision and productivity. The choice between manual and automated equipment depends on factors such as cost, complexity, production volume, and desired accuracy.

Key Differences Between Manual and Automated Equipment

Manual equipment requires human operation, relying heavily on physical labor and skill, which can limit productivity and precision. Automated equipment uses advanced technologies like robotics and sensors to perform tasks with higher speed, accuracy, and consistency. Key differences include operational efficiency, error rates, maintenance needs, and scalability, where automation significantly reduces human intervention and enhances overall performance.

Efficiency Comparison: Manual vs Automated Equipment

Automated equipment significantly enhances operational efficiency by reducing human error and increasing production speed, often achieving output rates up to 5 times higher than manual equipment. Manual equipment requires continuous human intervention, leading to inconsistent performance and longer cycle times, which can hinder scalability in large-scale manufacturing. Investing in automated systems typically results in lower labor costs and higher throughput, providing a competitive advantage in industries demanding precision and rapid turnaround.

Cost Analysis: Initial Investment and Long-Term Expenses

Manual equipment typically requires a lower initial investment compared to automated equipment, making it more accessible for small-scale operations. However, long-term expenses for manual equipment often increase due to higher labor costs and lower efficiency. Automated equipment demands a higher upfront cost but reduces ongoing operational expenses through improved productivity and reduced human error.

Labor Requirements and Workforce Implications

Manual equipment demands higher labor input due to the need for constant human operation, resulting in increased workforce requirements and potential for fatigue-related errors. Automated equipment reduces manual labor by performing repetitive tasks efficiently, allowing for a smaller, more technologically skilled workforce. Labor cost savings and improved productivity are direct benefits of automation, but it necessitates training and adaptation for workers to manage and maintain advanced systems.

Precision and Quality Control in Equipment Operation

Automated equipment consistently surpasses manual equipment in precision due to programmed calibration and real-time adjustments, minimizing human error during operations. Advanced sensors and integrated quality control systems in automated machinery enable continuous monitoring and instant feedback, ensuring higher product consistency and adherence to strict tolerances. Manual equipment relies heavily on operator skill, often resulting in variability in quality and precision, which can lead to increased waste and rework.

Safety Considerations for Manual and Automated Systems

Manual equipment operations often expose workers to higher risk due to direct physical interaction, increasing potential for injuries such as cuts, strains, and repetitive motion disorders. Automated systems enhance safety by minimizing human involvement, incorporating sensors, emergency stop features, and controlled environments to reduce accidents and ergonomic hazards. Proper safety protocols and regular maintenance remain critical to ensure both manual and automated equipment operate within safe standards and prevent malfunctions.

Flexibility and Adaptability in Production Processes

Manual equipment offers superior flexibility and adaptability in production processes due to its ability to be quickly reconfigured for different tasks without extensive reprogramming or setup changes. Automated equipment excels in high-volume, repetitive operations but often requires significant time and resources to adjust for new product variations or process modifications. Balancing manual and automated equipment enables optimized workflows that can respond dynamically to changing production demands and customization requirements.

Maintenance Demands: Manual vs Automated Equipment

Manual equipment requires frequent maintenance due to increased wear from human operation, often involving routine inspections, lubrication, and adjustment to prevent breakdowns. Automated equipment demands specialized maintenance focused on sensors, software updates, and calibration to ensure precision and reduce downtime. Predictive maintenance technologies enhance automated systems, minimizing unexpected failures compared to the more reactive upkeep of manual machinery.

Choosing the Right Equipment for Your Business Needs

Manual equipment offers greater control and cost-effectiveness for small-scale operations with low production volume, while automated equipment enhances efficiency and consistency in high-demand environments. Evaluating factors such as production speed, labor costs, maintenance requirements, and scalability is essential to align equipment choice with business objectives. Investing in technology that matches workflow complexity and budget constraints maximizes productivity and return on investment.

Manual equipment vs automated equipment Infographic

productdif.com

productdif.com