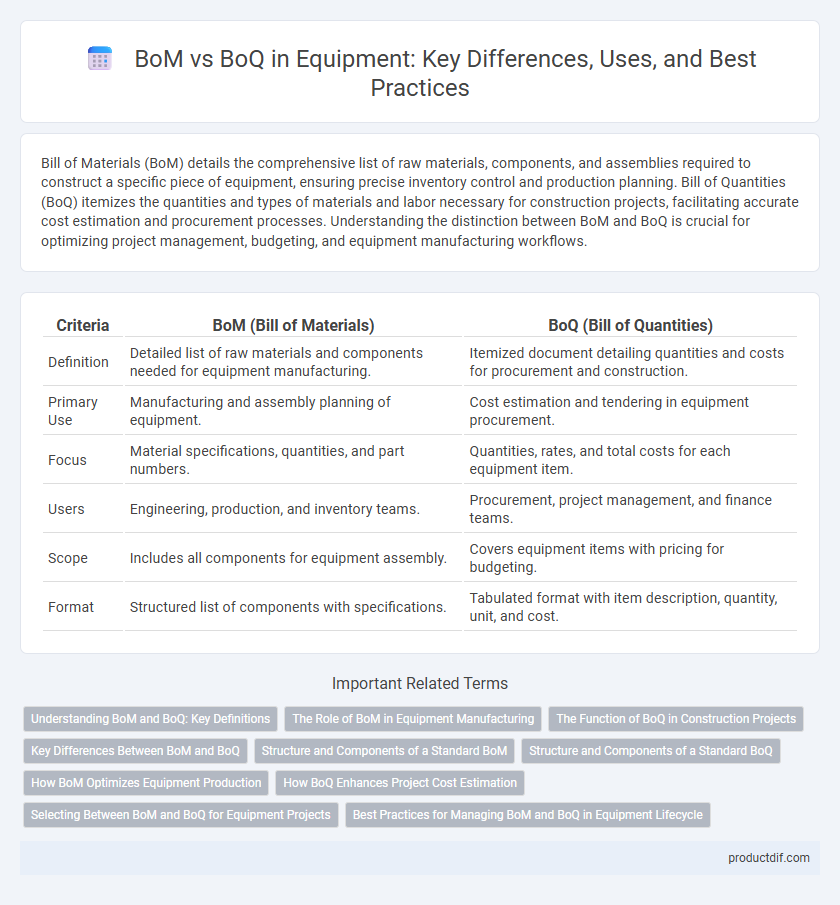

Bill of Materials (BoM) details the comprehensive list of raw materials, components, and assemblies required to construct a specific piece of equipment, ensuring precise inventory control and production planning. Bill of Quantities (BoQ) itemizes the quantities and types of materials and labor necessary for construction projects, facilitating accurate cost estimation and procurement processes. Understanding the distinction between BoM and BoQ is crucial for optimizing project management, budgeting, and equipment manufacturing workflows.

Table of Comparison

| Criteria | BoM (Bill of Materials) | BoQ (Bill of Quantities) |

|---|---|---|

| Definition | Detailed list of raw materials and components needed for equipment manufacturing. | Itemized document detailing quantities and costs for procurement and construction. |

| Primary Use | Manufacturing and assembly planning of equipment. | Cost estimation and tendering in equipment procurement. |

| Focus | Material specifications, quantities, and part numbers. | Quantities, rates, and total costs for each equipment item. |

| Users | Engineering, production, and inventory teams. | Procurement, project management, and finance teams. |

| Scope | Includes all components for equipment assembly. | Covers equipment items with pricing for budgeting. |

| Format | Structured list of components with specifications. | Tabulated format with item description, quantity, unit, and cost. |

Understanding BoM and BoQ: Key Definitions

Bill of Materials (BoM) is a comprehensive list detailing all components, parts, and materials required to manufacture a product, including quantities and specifications. Bill of Quantities (BoQ) is a document used in construction that itemizes materials, labor, and costs necessary for project completion, facilitating accurate budgeting and tendering. Understanding the distinction between BoM and BoQ is essential for equipment procurement and project management, as BoM focuses on product assembly while BoQ emphasizes project cost estimation.

The Role of BoM in Equipment Manufacturing

The Bill of Materials (BoM) plays a critical role in equipment manufacturing by providing a comprehensive list of raw materials, components, and assemblies required to build the final product. It ensures accurate procurement, cost estimation, and inventory management, enhancing production efficiency and reducing downtime. Unlike the Bill of Quantities (BoQ), which primarily focuses on construction projects, the BoM is tailored to the specific needs of manufacturing processes and equipment assembly.

The Function of BoQ in Construction Projects

The Bill of Quantities (BoQ) functions as a detailed document outlining the quantities and types of materials, labor, and equipment required for construction projects, ensuring accurate cost estimation and budget control. It provides a clear framework for contractors to prepare bids by itemizing each component based on the project specifications, enhancing transparency and reducing discrepancies. The BoQ also facilitates project management by enabling efficient resource allocation and tracking throughout the construction process.

Key Differences Between BoM and BoQ

Bill of Materials (BoM) details the comprehensive list of raw materials, components, and assemblies required to manufacture a product, emphasizing quantities and part specifications. Bill of Quantities (BoQ) provides a detailed summary of materials, labor, and costs needed for construction projects, aiding in budgeting and contract management. The key difference lies in BoM's focus on product assembly and component sourcing, while BoQ centers on cost estimation and project tendering.

Structure and Components of a Standard BoM

A standard Bill of Materials (BoM) is a detailed list that specifies the raw materials, components, assemblies, and sub-assemblies required to construct a piece of equipment. Each entry in the BoM includes part numbers, descriptions, quantities, and procurement information, ensuring precise structure and traceability. Unlike a Bill of Quantities (BoQ), which focuses on quantities and costs for project estimation, the BoM centers on the engineering and manufacturing process by clearly outlining the components' relationships and specifications.

Structure and Components of a Standard BoQ

A standard Bill of Quantities (BoQ) is a structured document detailing each component and quantity of equipment required for a project, organized systematically by work sections or trade categories. It includes detailed descriptions, units of measurement, and specified quantities for materials, labor, and equipment, facilitating precise cost estimation and procurement. The BoQ contrasts with a Bill of Materials (BoM), which focuses primarily on the complete list of raw materials and sub-assemblies needed for manufacturing or assembly.

How BoM Optimizes Equipment Production

A Bill of Materials (BoM) optimizes equipment production by providing a detailed, hierarchical list of components and raw materials required for each equipment assembly, enabling precise resource planning and inventory control. Unlike a Bill of Quantities (BoQ), which focuses primarily on quantities and costs, a BoM integrates component specifications and assembly sequences, reducing production errors and enhancing workflow efficiency. This comprehensive structure supports just-in-time manufacturing and minimizes material waste, accelerating the overall production cycle.

How BoQ Enhances Project Cost Estimation

Bill of Quantities (BoQ) enhances project cost estimation by providing a detailed, itemized list of materials, labor, and equipment required, allowing for precise budgeting and resource allocation. Unlike the Bill of Materials (BoM), which primarily lists components, BoQ includes quantities and cost rates, enabling accurate cost forecasting and financial control throughout the project lifecycle. This precision reduces the risk of budget overruns and supports efficient project management.

Selecting Between BoM and BoQ for Equipment Projects

Selecting between a Bill of Materials (BoM) and a Bill of Quantities (BoQ) for equipment projects depends on project scope and purpose; BoM details components and raw materials essential for manufacturing or assembly, providing precise material specifications and quantities. BoQ, on the other hand, emphasizes cost estimation and tendering by listing itemized descriptions and quantities of work and equipment needed on-site. Choosing the appropriate document ensures accurate project budgeting, procurement, and resource management in equipment installations.

Best Practices for Managing BoM and BoQ in Equipment Lifecycle

Effective management of Bill of Materials (BoM) and Bill of Quantities (BoQ) in equipment lifecycle involves maintaining accurate, up-to-date records that reflect component specifications and quantities throughout production and maintenance phases. Implementing integrated software solutions enhances real-time tracking, reduces errors, and ensures alignment between design, procurement, and assembly teams. Regular audits and cross-functional collaboration optimize cost control, streamline inventory management, and support timely equipment servicing.

BoM vs BoQ Infographic

productdif.com

productdif.com