Plug-and-play equipment offers easy installation and immediate usability, eliminating the need for complex wiring or technical expertise. Hardwired systems provide a stable, secure connection with enhanced reliability and reduced signal interference, ideal for permanent setups. Choosing between the two depends on the balance between convenience and long-term performance requirements.

Table of Comparison

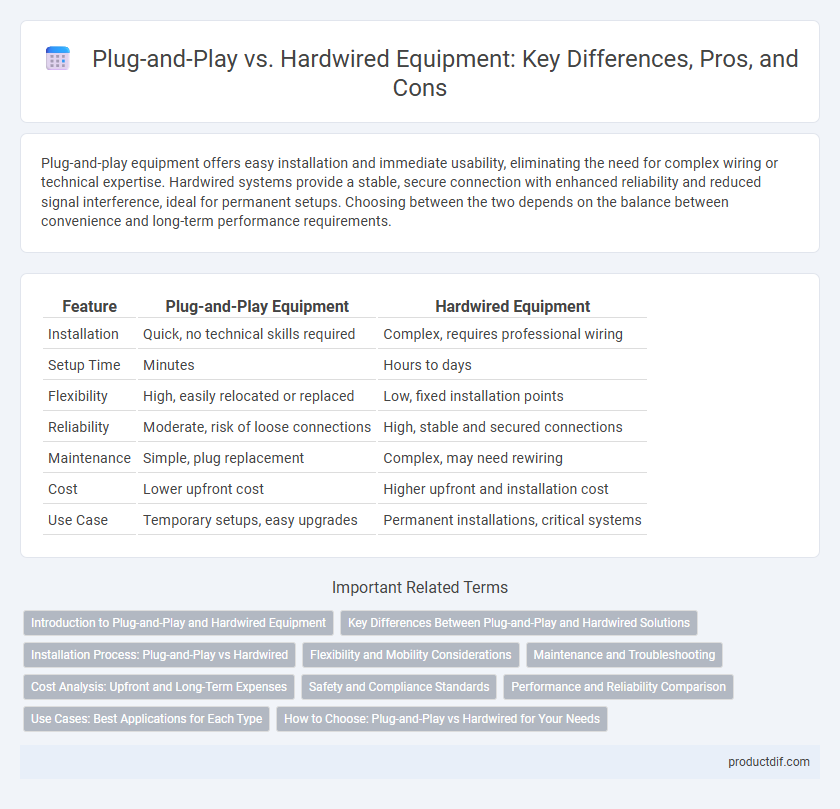

| Feature | Plug-and-Play Equipment | Hardwired Equipment |

|---|---|---|

| Installation | Quick, no technical skills required | Complex, requires professional wiring |

| Setup Time | Minutes | Hours to days |

| Flexibility | High, easily relocated or replaced | Low, fixed installation points |

| Reliability | Moderate, risk of loose connections | High, stable and secured connections |

| Maintenance | Simple, plug replacement | Complex, may need rewiring |

| Cost | Lower upfront cost | Higher upfront and installation cost |

| Use Case | Temporary setups, easy upgrades | Permanent installations, critical systems |

Introduction to Plug-and-Play and Hardwired Equipment

Plug-and-play equipment offers immediate usability by automatically recognizing and configuring devices without manual installation, making it ideal for users seeking convenience and quick setup. Hardwired equipment requires direct physical connections and manual configuration, providing more secure and stable performance for critical or permanent installations. Choosing between plug-and-play and hardwired systems depends on factors like ease of use, installation complexity, and the level of reliability needed for specific applications.

Key Differences Between Plug-and-Play and Hardwired Solutions

Plug-and-play equipment offers seamless installation by automatically recognizing devices without manual configuration, enhancing convenience for users and reducing setup time. Hardwired solutions require direct physical connections and often involve complex wiring and configuration, providing a more stable and secure connection suited for permanent installations. Key differences lie in flexibility, ease of installation, and reliability, with plug-and-play favoring adaptability and hardwired systems emphasizing durability and consistent performance.

Installation Process: Plug-and-Play vs Hardwired

Plug-and-play equipment simplifies installation by requiring minimal setup, allowing devices to be connected and operational almost immediately without specialized tools or technical expertise. Hardwired installations involve directly connecting devices to electrical or data systems, demanding professional skills, precise wiring, and often longer installation times to ensure safety and compliance with standards. Choosing between plug-and-play and hardwired options depends on the complexity of the system, installation environment, and long-term maintenance considerations.

Flexibility and Mobility Considerations

Plug-and-play equipment offers enhanced flexibility by enabling quick installation and easy relocation without specialized tools or technical expertise, making it ideal for dynamic work environments. Hardwired systems provide stable, permanent connections but limit mobility due to fixed installation points and complex alterations. Choosing between plug-and-play and hardwired configurations depends on the need for adaptability versus reliability in equipment deployment.

Maintenance and Troubleshooting

Plug-and-play equipment reduces maintenance time and simplifies troubleshooting by allowing quick replacement and minimal wiring complexity, which minimizes downtime. Hardwired systems often require specialized skills for maintenance and troubleshooting due to their integrated wiring and configuration, increasing repair time and potential errors. Efficient diagnostics and component swaps are more seamless with plug-and-play designs, making them ideal for environments prioritizing rapid system recovery.

Cost Analysis: Upfront and Long-Term Expenses

Plug-and-play equipment typically involves lower upfront costs due to easy installation and minimal labor requirements, making it cost-effective for immediate use. Hardwired systems, while often more expensive initially due to professional installation and wiring materials, offer greater long-term savings through enhanced durability and reduced maintenance needs. Evaluating total cost of ownership reveals that plug-and-play solutions suit short-term budgets, whereas hardwired setups provide better value for sustained operational efficiency.

Safety and Compliance Standards

Plug-and-play equipment ensures enhanced safety by minimizing wiring errors and electrical hazards compared to hardwired systems, which require professional installation to meet strict compliance standards. Plug-and-play devices often feature built-in safeguards aligned with UL and IEC certifications, streamlining adherence to national and international safety regulations. Hardwired installations demand rigorous testing and adherence to NEC and OSHA codes to prevent potential risks, emphasizing the importance of certified electricians for compliance and safety assurance.

Performance and Reliability Comparison

Plug-and-play equipment offers quick installation and greater flexibility but may experience occasional latency or connectivity issues affecting performance. Hardwired systems provide more consistent, stable connections with lower latency, enhancing reliability and overall operational efficiency. For critical applications demanding maximum uptime and minimal signal interference, hardwired configurations typically outperform plug-and-play setups.

Use Cases: Best Applications for Each Type

Plug-and-play equipment suits environments requiring quick installation and frequent relocation, such as temporary workstations and event setups, where flexibility and ease of use are critical. Hardwired systems excel in permanent installations like industrial automation and building infrastructure, providing enhanced reliability and reduced interference for essential operations. Choosing based on operational stability versus adaptability optimizes performance and maintenance in specific industrial and commercial settings.

How to Choose: Plug-and-Play vs Hardwired for Your Needs

Choosing between plug-and-play and hardwired equipment depends on factors such as installation complexity, flexibility, and long-term maintenance. Plug-and-play devices offer quick setup and easy mobility, ideal for temporary or frequently changing environments, while hardwired systems provide higher reliability and security, suitable for permanent installations requiring stable connectivity. Assess your specific requirements for user convenience, durability, and technical support to determine the best fit for your equipment needs.

Plug-and-play vs Hardwired Infographic

productdif.com

productdif.com