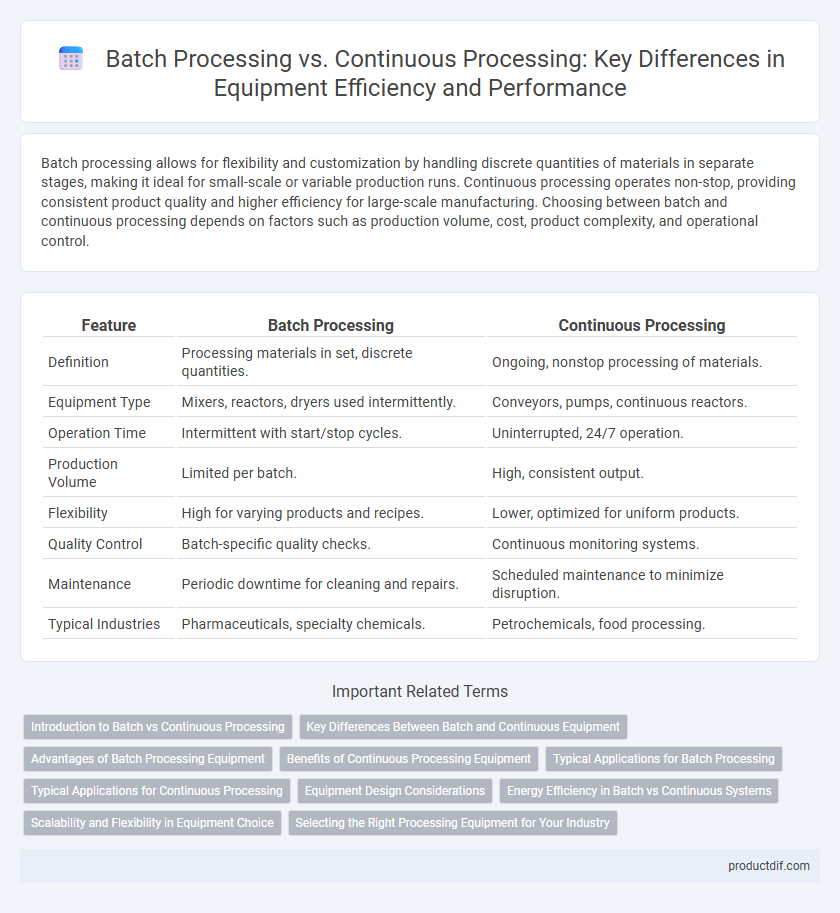

Batch processing allows for flexibility and customization by handling discrete quantities of materials in separate stages, making it ideal for small-scale or variable production runs. Continuous processing operates non-stop, providing consistent product quality and higher efficiency for large-scale manufacturing. Choosing between batch and continuous processing depends on factors such as production volume, cost, product complexity, and operational control.

Table of Comparison

| Feature | Batch Processing | Continuous Processing |

|---|---|---|

| Definition | Processing materials in set, discrete quantities. | Ongoing, nonstop processing of materials. |

| Equipment Type | Mixers, reactors, dryers used intermittently. | Conveyors, pumps, continuous reactors. |

| Operation Time | Intermittent with start/stop cycles. | Uninterrupted, 24/7 operation. |

| Production Volume | Limited per batch. | High, consistent output. |

| Flexibility | High for varying products and recipes. | Lower, optimized for uniform products. |

| Quality Control | Batch-specific quality checks. | Continuous monitoring systems. |

| Maintenance | Periodic downtime for cleaning and repairs. | Scheduled maintenance to minimize disruption. |

| Typical Industries | Pharmaceuticals, specialty chemicals. | Petrochemicals, food processing. |

Introduction to Batch vs Continuous Processing

Batch processing involves handling equipment operations in discrete, separate quantities where materials are processed in defined groups, allowing flexibility and customization for varied product types. Continuous processing utilizes equipment designed for uninterrupted, steady-state production, optimizing efficiency and consistency in high-volume manufacturing environments. Selection between batch and continuous processing depends on factors such as production scale, product complexity, equipment capabilities, and desired throughput.

Key Differences Between Batch and Continuous Equipment

Batch processing equipment handles materials in discrete, separate quantities, allowing precise control and flexibility for customized production runs. Continuous processing equipment operates without interruption, enabling high throughput and consistent product quality by maintaining steady conditions. Key differences include scalability, operational complexity, and suitability for varying production volumes, with batch systems favoring variability and continuous systems optimizing efficiency.

Advantages of Batch Processing Equipment

Batch processing equipment offers superior flexibility, allowing manufacturers to produce multiple product variations without extensive downtime. This type of equipment is ideal for small to medium production runs, reducing waste and optimizing resource use. Maintenance and cleaning are simpler and faster compared to continuous processing systems, enhancing operational efficiency.

Benefits of Continuous Processing Equipment

Continuous processing equipment offers enhanced production efficiency by enabling nonstop operation, significantly reducing downtime compared to batch processing. It ensures consistent product quality through steady-state conditions, minimizing variability and waste. This equipment also improves scalability and automation potential, leading to lower labor costs and better integration within modern manufacturing systems.

Typical Applications for Batch Processing

Batch processing equipment is commonly used in pharmaceutical manufacturing, food production, and specialty chemical industries where precise control over individual production runs is required. Typical applications include making customized formulations, small-scale production, and handling products with varying recipes or batch sizes. This method allows for thorough quality control, flexibility, and easier management of complex processes compared to continuous processing systems.

Typical Applications for Continuous Processing

Continuous processing is commonly used in industries requiring large-scale and consistent output, such as chemical manufacturing, pharmaceuticals, and food and beverage production. It is ideal for processes involving liquids, gases, or fine powders where maintaining steady-state conditions improves product quality and operational efficiency. Typical applications include oil refining, polymer production, and wastewater treatment where uninterrupted material flow is essential.

Equipment Design Considerations

Batch processing equipment requires versatile design features to accommodate varying product volumes and frequent changeovers, emphasizing modularity and easy cleaning mechanisms. Continuous processing equipment demands robust materials and precise control systems to maintain consistent flow rates and temperature regulation, optimizing for high throughput and minimal downtime. Both designs prioritize scalability and automation integration to enhance operational efficiency and product quality in industrial applications.

Energy Efficiency in Batch vs Continuous Systems

Continuous processing systems often achieve higher energy efficiency compared to batch processing by maintaining steady-state operations that minimize energy loss during startups and shutdowns. In batch systems, frequent cycling and equipment downtime lead to increased energy consumption due to reheating and cooling phases. Optimizing energy use in continuous equipment involves advanced monitoring and control technologies that reduce thermal gradients and maximize heat recovery.

Scalability and Flexibility in Equipment Choice

Batch processing equipment excels in flexibility, allowing manufacturers to produce varied product types and smaller quantities without extensive reconfiguration. Continuous processing systems offer superior scalability, capable of handling large volumes consistently with minimal downtime, ideal for high-demand production. Selecting between batch and continuous equipment depends on production scale requirements and the need for versatility in product output.

Selecting the Right Processing Equipment for Your Industry

Batch processing equipment offers flexibility for small to medium production runs, making it ideal for industries requiring frequent product changes and quality control, such as pharmaceuticals and specialty chemicals. Continuous processing equipment provides high efficiency and consistent product quality in large-scale operations, suitable for industries like petrochemicals and food manufacturing. Selecting the right processing equipment depends on production volume, product complexity, and desired output consistency to optimize operational efficiency and cost-effectiveness.

Batch Processing vs Continuous Processing Infographic

productdif.com

productdif.com