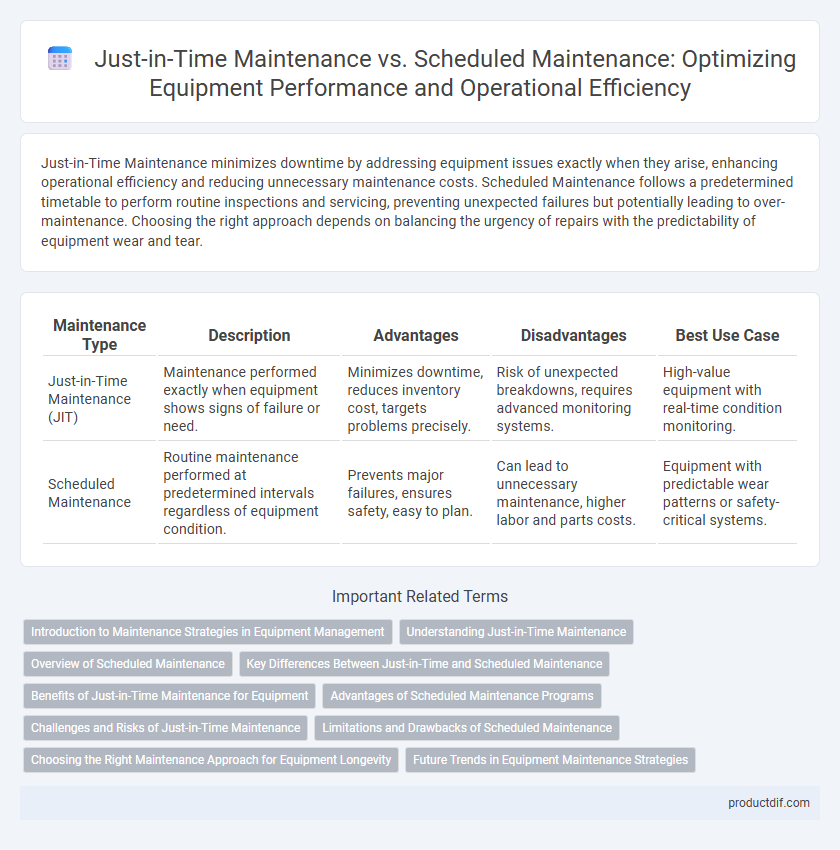

Just-in-Time Maintenance minimizes downtime by addressing equipment issues exactly when they arise, enhancing operational efficiency and reducing unnecessary maintenance costs. Scheduled Maintenance follows a predetermined timetable to perform routine inspections and servicing, preventing unexpected failures but potentially leading to over-maintenance. Choosing the right approach depends on balancing the urgency of repairs with the predictability of equipment wear and tear.

Table of Comparison

| Maintenance Type | Description | Advantages | Disadvantages | Best Use Case |

|---|---|---|---|---|

| Just-in-Time Maintenance (JIT) | Maintenance performed exactly when equipment shows signs of failure or need. | Minimizes downtime, reduces inventory cost, targets problems precisely. | Risk of unexpected breakdowns, requires advanced monitoring systems. | High-value equipment with real-time condition monitoring. |

| Scheduled Maintenance | Routine maintenance performed at predetermined intervals regardless of equipment condition. | Prevents major failures, ensures safety, easy to plan. | Can lead to unnecessary maintenance, higher labor and parts costs. | Equipment with predictable wear patterns or safety-critical systems. |

Introduction to Maintenance Strategies in Equipment Management

Just-in-time maintenance minimizes downtime by performing repairs precisely when needed, based on real-time equipment condition monitoring and predictive analytics. Scheduled maintenance relies on predetermined intervals to conduct inspections and servicing, reducing unexpected failures but potentially incurring unnecessary maintenance tasks. Effective equipment management balances these strategies to optimize asset reliability, operational efficiency, and maintenance costs.

Understanding Just-in-Time Maintenance

Just-in-Time Maintenance focuses on performing maintenance tasks precisely when equipment shows signs of wear or potential failure, minimizing downtime and reducing unnecessary part replacements. This approach relies heavily on real-time monitoring, predictive analytics, and condition-based sensors to optimize equipment reliability and extend asset life. Implementing Just-in-Time Maintenance enhances operational efficiency and lowers maintenance costs by aligning interventions with actual equipment needs rather than fixed schedules.

Overview of Scheduled Maintenance

Scheduled maintenance involves performing equipment upkeep at predetermined intervals based on time or usage, ensuring consistent reliability and preventing unexpected breakdowns. This proactive approach minimizes downtime by addressing wear and tear before failures occur, optimizing operational efficiency. Key tasks include inspections, lubrication, parts replacement, and system adjustments aligned with manufacturer recommendations or industry standards.

Key Differences Between Just-in-Time and Scheduled Maintenance

Just-in-Time Maintenance emphasizes performing repairs precisely when needed, reducing downtime and inventory costs by addressing equipment issues only as they arise. Scheduled Maintenance follows a predetermined timetable to perform regular inspections and part replacements, aiming to prevent unexpected failures through consistent upkeep. Key differences include the reactive nature of Just-in-Time Maintenance versus the proactive approach of Scheduled Maintenance, impacting resource allocation, risk management, and operational efficiency.

Benefits of Just-in-Time Maintenance for Equipment

Just-in-Time Maintenance reduces equipment downtime by addressing issues precisely when needed, enhancing operational efficiency and minimizing unnecessary inspections. This approach lowers maintenance costs by preventing over-servicing and focusing resources on critical repairs, extending equipment lifespan. Improved asset reliability and optimized spare parts inventory further contribute to increased productivity and cost savings in industrial operations.

Advantages of Scheduled Maintenance Programs

Scheduled maintenance programs enhance equipment reliability by systematically addressing wear and tear before failures occur, reducing unscheduled downtime significantly. They enable better resource allocation and budgeting through predictable maintenance intervals, leading to improved cost management. Consistent inspections and servicing under scheduled programs extend equipment lifespan and ensure compliance with safety standards.

Challenges and Risks of Just-in-Time Maintenance

Just-in-Time Maintenance poses challenges such as increased risk of unexpected equipment failure due to minimal buffer time for repairs, which can lead to costly downtime and production losses. The dependency on accurate condition monitoring and prompt response times makes it vulnerable to errors or delays in diagnostics, potentially causing critical breakdowns. Limited spare parts availability and tight scheduling further exacerbate risks, reducing flexibility in addressing unforeseen maintenance needs.

Limitations and Drawbacks of Scheduled Maintenance

Scheduled maintenance often leads to unnecessary downtime and increased labor costs due to routine servicing regardless of actual equipment condition. This approach may result in premature replacement of parts, contributing to higher material expenses and resource wastage. Additionally, scheduled maintenance lacks flexibility to address unexpected failures, potentially causing extended equipment unavailability and production delays.

Choosing the Right Maintenance Approach for Equipment Longevity

Just-in-Time Maintenance minimizes downtime by addressing equipment issues precisely when they arise, reducing unnecessary servicing costs and extending component life through targeted repairs. Scheduled Maintenance relies on predetermined intervals for inspections and part replacements, preventing unexpected failures and ensuring consistent operational reliability. Selecting the optimal maintenance strategy depends on equipment criticality, operational demands, and cost considerations to maximize machinery longevity and performance.

Future Trends in Equipment Maintenance Strategies

Future trends in equipment maintenance strategies emphasize predictive analytics and IoT integration, enhancing the precision of just-in-time maintenance to minimize downtime and reduce costs. Scheduled maintenance continues evolving with AI-driven scheduling tools that optimize service intervals based on real-time equipment health data. Advances in machine learning and big data analytics enable dynamic maintenance planning, merging the benefits of both just-in-time and scheduled approaches for improved operational efficiency.

Just-in-Time Maintenance vs Scheduled Maintenance Infographic

productdif.com

productdif.com