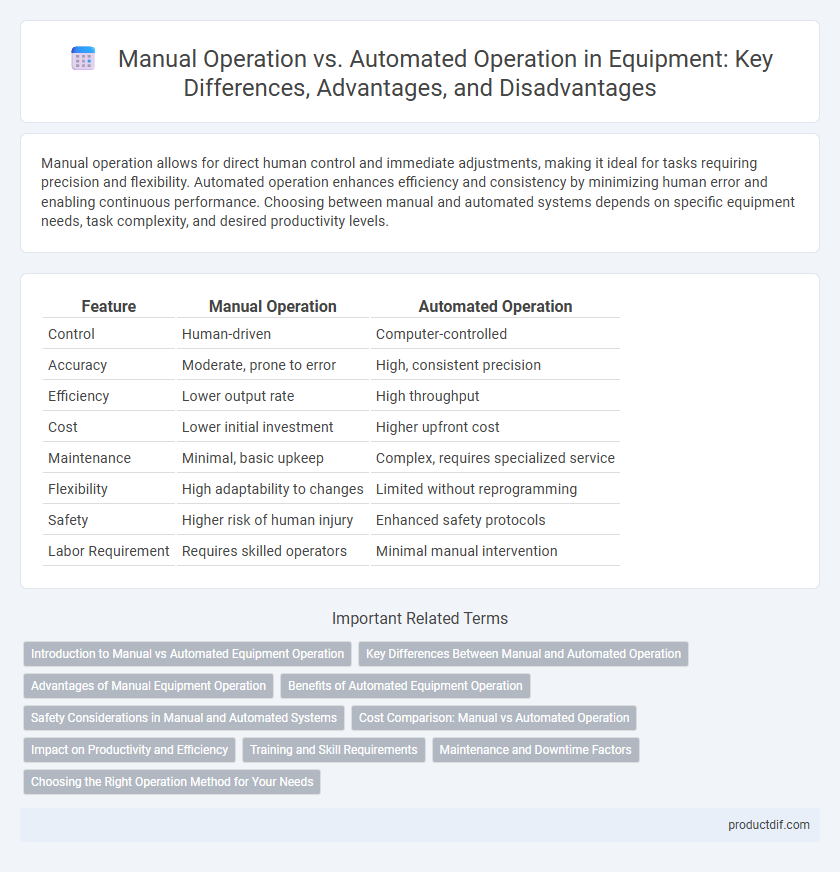

Manual operation allows for direct human control and immediate adjustments, making it ideal for tasks requiring precision and flexibility. Automated operation enhances efficiency and consistency by minimizing human error and enabling continuous performance. Choosing between manual and automated systems depends on specific equipment needs, task complexity, and desired productivity levels.

Table of Comparison

| Feature | Manual Operation | Automated Operation |

|---|---|---|

| Control | Human-driven | Computer-controlled |

| Accuracy | Moderate, prone to error | High, consistent precision |

| Efficiency | Lower output rate | High throughput |

| Cost | Lower initial investment | Higher upfront cost |

| Maintenance | Minimal, basic upkeep | Complex, requires specialized service |

| Flexibility | High adaptability to changes | Limited without reprogramming |

| Safety | Higher risk of human injury | Enhanced safety protocols |

| Labor Requirement | Requires skilled operators | Minimal manual intervention |

Introduction to Manual vs Automated Equipment Operation

Manual operation of equipment requires direct human intervention to control machinery, often involving physical effort, detailed attention, and real-time decision-making. Automated operation utilizes programmed systems and sensors to perform tasks with minimal human input, increasing efficiency, precision, and safety. Advances in automation technology enable seamless integration with existing manual processes, optimizing production workflows and reducing operational risks.

Key Differences Between Manual and Automated Operation

Manual operation relies on human intervention for controlling equipment, requiring physical input and constant monitoring, which can lead to variability in performance and increased labor costs. Automated operation uses programmable systems and sensors to manage equipment functions with high precision, improving efficiency, consistency, and safety while reducing human error. Automated systems enable real-time data collection and predictive maintenance, whereas manual systems lack continuous analytics and responsiveness.

Advantages of Manual Equipment Operation

Manual equipment operation offers precise control and immediate responsiveness, allowing operators to make quick adjustments based on real-time conditions. It enhances situational awareness and reduces reliance on complex software, lowering the risk of malfunctions due to system errors. Manual operation also facilitates easier maintenance and troubleshooting by enabling direct interaction with equipment components.

Benefits of Automated Equipment Operation

Automated equipment operation enhances precision and consistency, reducing human error and increasing overall productivity. Advanced sensors and real-time data analysis enable efficient monitoring and maintenance, minimizing downtime and operational costs. Automation also improves safety by limiting direct human interaction with potentially hazardous machinery, promoting a secure working environment.

Safety Considerations in Manual and Automated Systems

Manual operation in equipment requires constant human vigilance, increasing the risk of errors and accidents due to fatigue or distraction. Automated systems incorporate advanced sensors and control algorithms to continuously monitor operational parameters, thereby reducing the likelihood of safety incidents. Safety protocols in automated systems rely on fail-safes and emergency shutdown mechanisms, whereas manual systems depend heavily on operator training and adherence to safety guidelines.

Cost Comparison: Manual vs Automated Operation

Manual operation typically incurs higher labor costs due to the need for continuous human involvement and skill-based tasks, whereas automated operation requires significant upfront investment in technology but reduces ongoing labor expenses. Automated systems improve cost efficiency over time by minimizing human error, increasing throughput, and lowering maintenance costs with predictive diagnostics. The total cost of ownership favors automation in large-scale or repetitive processes, where operational savings outweigh initial capital expenditures.

Impact on Productivity and Efficiency

Manual operation in equipment often results in slower production rates and higher error margins, limiting overall efficiency and productivity. Automated operation utilizes advanced sensors and control systems to streamline processes, reduce downtime, and enhance precision. Data-driven automation consistently improves throughput while minimizing labor costs and operational inefficiencies.

Training and Skill Requirements

Manual operation of equipment demands extensive hands-on training and specialized skills to ensure precision and safety, often requiring operators to understand mechanical systems deeply. Automated operation reduces the need for manual dexterity, shifting the training focus toward programming, monitoring, and troubleshooting complex control software. Skilled technicians must adapt to evolving technology by acquiring expertise in automation systems to maintain efficiency and minimize downtime.

Maintenance and Downtime Factors

Manual operation requires frequent maintenance due to higher wear and tear from human error and inconsistent handling, leading to increased downtime. Automated operation systems utilize predictive maintenance technologies and sensor data analytics to minimize unplanned outages and optimize equipment lifespan. Implementing automation reduces maintenance frequency and downtime by enabling real-time monitoring and faster fault detection.

Choosing the Right Operation Method for Your Needs

Manual operation offers precise control and adaptability for tasks requiring human judgment, while automated operation enhances efficiency and consistency in repetitive processes. Selecting the right method depends on factors such as task complexity, volume, and desired accuracy. Analyzing workflow requirements and equipment capabilities ensures optimal performance and cost-effectiveness.

Manual Operation vs Automated Operation Infographic

productdif.com

productdif.com