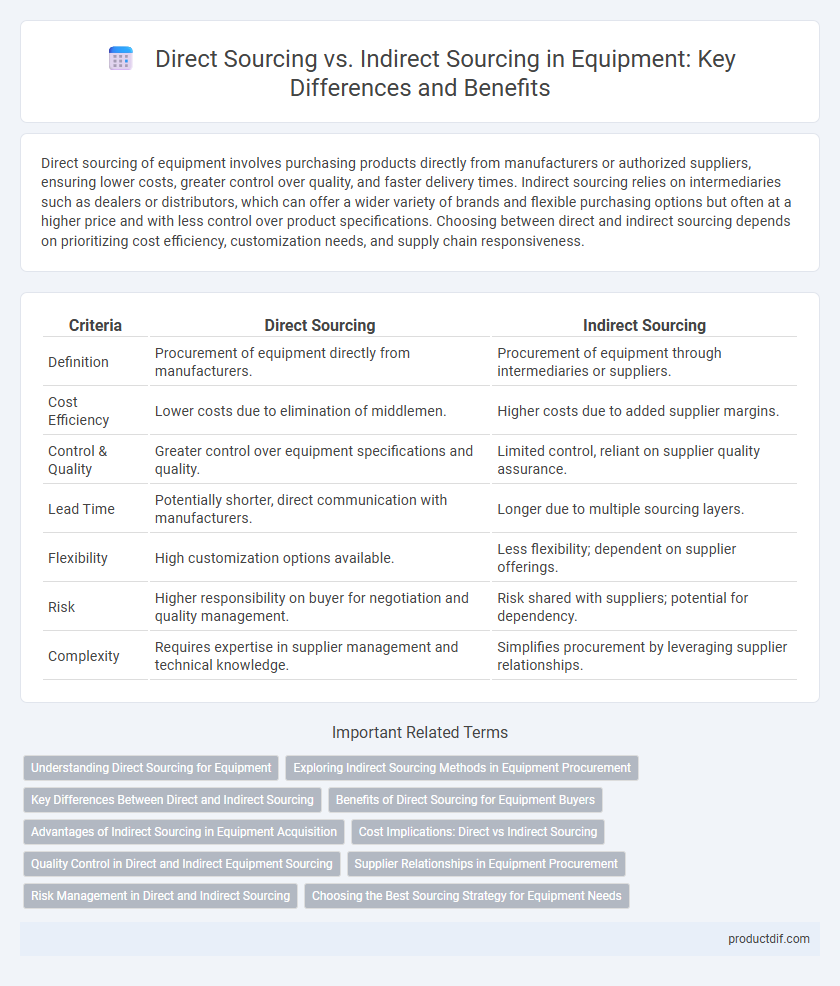

Direct sourcing of equipment involves purchasing products directly from manufacturers or authorized suppliers, ensuring lower costs, greater control over quality, and faster delivery times. Indirect sourcing relies on intermediaries such as dealers or distributors, which can offer a wider variety of brands and flexible purchasing options but often at a higher price and with less control over product specifications. Choosing between direct and indirect sourcing depends on prioritizing cost efficiency, customization needs, and supply chain responsiveness.

Table of Comparison

| Criteria | Direct Sourcing | Indirect Sourcing |

|---|---|---|

| Definition | Procurement of equipment directly from manufacturers. | Procurement of equipment through intermediaries or suppliers. |

| Cost Efficiency | Lower costs due to elimination of middlemen. | Higher costs due to added supplier margins. |

| Control & Quality | Greater control over equipment specifications and quality. | Limited control, reliant on supplier quality assurance. |

| Lead Time | Potentially shorter, direct communication with manufacturers. | Longer due to multiple sourcing layers. |

| Flexibility | High customization options available. | Less flexibility; dependent on supplier offerings. |

| Risk | Higher responsibility on buyer for negotiation and quality management. | Risk shared with suppliers; potential for dependency. |

| Complexity | Requires expertise in supplier management and technical knowledge. | Simplifies procurement by leveraging supplier relationships. |

Understanding Direct Sourcing for Equipment

Direct sourcing for equipment involves purchasing machinery or tools directly from manufacturers or authorized suppliers, ensuring higher quality control and cost savings compared to intermediaries. This approach streamlines procurement, reduces lead times, and allows businesses to negotiate customized terms and warranties specific to their operational needs. Companies that adopt direct sourcing optimize equipment lifecycle management and benefit from improved supplier relationships and enhanced product traceability.

Exploring Indirect Sourcing Methods in Equipment Procurement

Indirect sourcing in equipment procurement involves purchasing through intermediaries such as distributors, agents, or brokers, which can offer greater flexibility and access to a wider range of suppliers. This method often reduces administrative burdens and leverages supplier relationships for better pricing and service levels. Companies benefit from indirect sourcing by gaining faster delivery times and minimizing risks associated with direct supply chain management.

Key Differences Between Direct and Indirect Sourcing

Direct sourcing involves procuring equipment directly from manufacturers, ensuring lower costs and greater control over quality and specifications. Indirect sourcing, on the other hand, relies on intermediaries or suppliers, which can simplify the procurement process but often results in higher prices and less transparency. The key differences lie in cost efficiency, control over product quality, and the complexity of the supply chain management.

Benefits of Direct Sourcing for Equipment Buyers

Direct sourcing for equipment buyers offers cost savings by eliminating intermediaries, resulting in lower purchase prices and reduced fees. Buyers gain greater control over product quality and specifications through direct communication with manufacturers, ensuring equipment meets exact operational requirements. This approach also accelerates procurement timelines, enhancing supply chain efficiency and minimizing downtime.

Advantages of Indirect Sourcing in Equipment Acquisition

Indirect sourcing in equipment acquisition offers access to a broader range of suppliers, ensuring competitive pricing and diverse product options. It enables companies to leverage established vendor relationships and benefit from bundled services like maintenance and training. This approach also reduces administrative burdens by centralizing procurement through intermediaries, streamlining the acquisition process.

Cost Implications: Direct vs Indirect Sourcing

Direct sourcing typically reduces costs by eliminating intermediaries, resulting in lower procurement expenses and improved price transparency. Indirect sourcing often incurs higher costs due to third-party markups, extended lead times, and additional administrative overhead. Evaluating total cost of ownership, including logistics, quality control, and supplier relationship management, is crucial for optimizing equipment procurement strategies.

Quality Control in Direct and Indirect Equipment Sourcing

Direct sourcing of equipment ensures stringent quality control through direct inspections and supplier audits, reducing defects and compliance risks. Indirect sourcing often relies on intermediaries, which can dilute quality oversight and increase the likelihood of inconsistencies or substandard equipment. Implementing robust quality assurance protocols in direct sourcing streamlines compliance with industry standards and enhances overall equipment reliability.

Supplier Relationships in Equipment Procurement

Direct sourcing in equipment procurement fosters stronger supplier relationships by enabling direct communication and collaboration, which often results in customized solutions and better pricing. Indirect sourcing typically involves intermediaries, diluting supplier engagement and potentially limiting transparency and responsiveness. Building long-term partnerships with direct suppliers enhances reliability, quality control, and streamlined supply chain management in equipment acquisition.

Risk Management in Direct and Indirect Sourcing

Direct sourcing enables companies to exercise greater control over supplier selection and quality standards, significantly reducing risks related to compliance and supply chain disruptions. In contrast, indirect sourcing often involves third-party intermediaries, increasing exposure to risks such as miscommunication, hidden costs, and reduced traceability of equipment origins. Effective risk management in direct sourcing relies on thorough supplier vetting and ongoing performance monitoring, while indirect sourcing requires robust contract management and supplier relationship oversight to mitigate potential vulnerabilities.

Choosing the Best Sourcing Strategy for Equipment Needs

Direct sourcing for equipment enables companies to establish stronger supplier relationships, ensuring better quality control and often reduced costs by eliminating intermediaries. Indirect sourcing involves purchasing through third parties or distributors, which can offer greater flexibility and access to diverse equipment options but may increase expenses and complicate supply chains. Selecting the best sourcing strategy depends on factors such as budget constraints, required customization, lead times, and the critical nature of the equipment for operations.

Direct sourcing vs Indirect sourcing Infographic

productdif.com

productdif.com