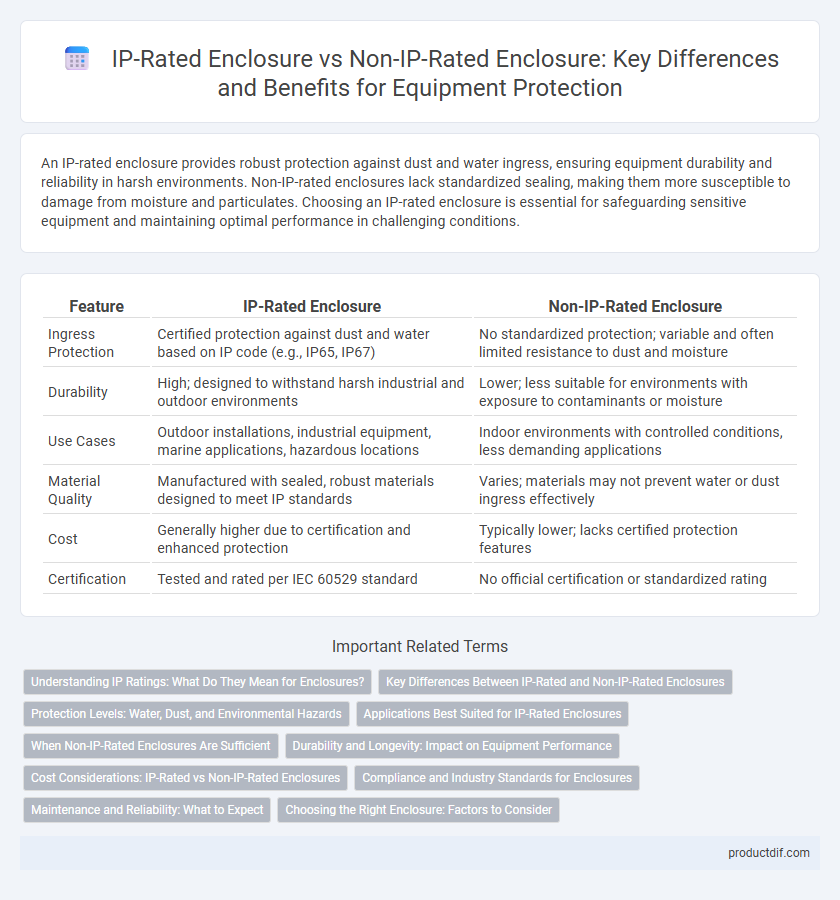

An IP-rated enclosure provides robust protection against dust and water ingress, ensuring equipment durability and reliability in harsh environments. Non-IP-rated enclosures lack standardized sealing, making them more susceptible to damage from moisture and particulates. Choosing an IP-rated enclosure is essential for safeguarding sensitive equipment and maintaining optimal performance in challenging conditions.

Table of Comparison

| Feature | IP-Rated Enclosure | Non-IP-Rated Enclosure |

|---|---|---|

| Ingress Protection | Certified protection against dust and water based on IP code (e.g., IP65, IP67) | No standardized protection; variable and often limited resistance to dust and moisture |

| Durability | High; designed to withstand harsh industrial and outdoor environments | Lower; less suitable for environments with exposure to contaminants or moisture |

| Use Cases | Outdoor installations, industrial equipment, marine applications, hazardous locations | Indoor environments with controlled conditions, less demanding applications |

| Material Quality | Manufactured with sealed, robust materials designed to meet IP standards | Varies; materials may not prevent water or dust ingress effectively |

| Cost | Generally higher due to certification and enhanced protection | Typically lower; lacks certified protection features |

| Certification | Tested and rated per IEC 60529 standard | No official certification or standardized rating |

Understanding IP Ratings: What Do They Mean for Enclosures?

IP-rated enclosures provide standardized protection against solids and liquids based on the IP (Ingress Protection) code, ensuring equipment inside remains safe from dust, water, and other environmental factors. Non-IP-rated enclosures lack this verified protection, increasing the risk of damage or operational failure in harsh conditions. Understanding IP ratings, such as IP65 or IP67, is crucial for selecting enclosures that meet specific environmental requirements and optimize equipment durability and performance.

Key Differences Between IP-Rated and Non-IP-Rated Enclosures

IP-rated enclosures provide certified protection against solid objects and water ingress, classified by standardized IP codes such as IP65 or IP67, ensuring durability in harsh environments. Non-IP-rated enclosures lack this formal certification, potentially exposing sensitive equipment to dust, moisture, and contaminants, which can lead to operational failures. Choosing IP-rated enclosures is critical for applications demanding stringent environmental protection and reliability.

Protection Levels: Water, Dust, and Environmental Hazards

IP-rated enclosures provide standardized protection levels against water, dust, and environmental hazards, measured by specific IP codes such as IP65 or IP67, ensuring reliable sealing and defense against particle ingress and moisture exposure. Non-IP-rated enclosures lack these defined protection standards, often resulting in vulnerability to dust accumulation, water ingress, and damage from environmental contaminants. Selecting IP-rated enclosures is crucial for equipment operating in harsh or variable conditions, guaranteeing enhanced durability and operational integrity.

Applications Best Suited for IP-Rated Enclosures

IP-rated enclosures provide superior protection against dust, water, and other environmental factors, making them ideal for outdoor equipment, industrial machinery, and harsh environments such as construction sites or marine applications. These enclosures ensure reliable operation of sensitive electronics by preventing ingress of contaminants and moisture, crucial for maintaining performance in unpredictable conditions. Non-IP-rated enclosures lack such protection, limiting their use to controlled indoor settings where exposure risks are minimal.

When Non-IP-Rated Enclosures Are Sufficient

Non-IP-rated enclosures are sufficient in environments where equipment is protected from dust, water, and other contaminants, such as indoor settings with controlled climate and minimal exposure to moisture or debris. These enclosures offer cost-effective protection for electronic components that do not require stringent ingress protection standards. Selecting non-IP-rated enclosures reduces expenses without compromising safety in low-risk applications like office spaces or clean manufacturing areas.

Durability and Longevity: Impact on Equipment Performance

IP-rated enclosures provide superior durability and longevity by offering robust protection against dust, water, and other environmental hazards, significantly extending equipment lifespan. Non-IP-rated enclosures lack this specialized sealing, which increases the risk of corrosion, contamination, and mechanical damage, leading to reduced equipment reliability and higher maintenance costs. Investing in IP-rated enclosures enhances overall equipment performance by minimizing downtime and safeguarding sensitive components from harsh industrial conditions.

Cost Considerations: IP-Rated vs Non-IP-Rated Enclosures

IP-rated enclosures typically incur higher upfront costs due to materials and sealing technologies that ensure protection against dust, water, and other environmental factors, essential for maintaining equipment longevity in harsh conditions. Non-IP-rated enclosures offer cost savings initially but may lead to increased maintenance and replacement expenses over time, especially in environments prone to moisture or particulate exposure. Investing in an IP-rated enclosure provides long-term value by reducing downtime and safeguarding sensitive equipment, which often outweighs the initial price difference.

Compliance and Industry Standards for Enclosures

IP-rated enclosures comply with international standards such as IEC 60529, ensuring robust protection against dust and water ingress, which is critical for maintaining equipment integrity in harsh environments. Non-IP-rated enclosures lack this certification, potentially failing to meet regulatory requirements for safety and durability in industrial applications. Adhering to compliance standards with IP-rated enclosures mitigates risks of equipment failure and aligns with industry best practices for operational reliability.

Maintenance and Reliability: What to Expect

IP-rated enclosures offer superior protection against dust, water, and environmental hazards, significantly reducing equipment failure and maintenance frequency. Maintenance for IP-rated enclosures typically involves less frequent inspections and replacements due to their robust sealing standards like IP65 or higher. Non-IP-rated enclosures often require more regular upkeep to address corrosion, particulate ingress, and moisture damage, which can compromise equipment reliability and lead to increased downtime.

Choosing the Right Enclosure: Factors to Consider

Selecting the right enclosure involves evaluating its IP rating, which indicates protection against dust and water ingress, essential for ensuring equipment longevity and operational reliability. An IP-rated enclosure offers specific defense levels based on IEC standards, crucial for environments exposed to moisture, dust, or harsh conditions, whereas non-IP-rated enclosures may lack adequate sealing and durability. Consider the operational environment, exposure risks, and compliance requirements to determine whether an IP-rated enclosure is necessary for safeguarding sensitive equipment effectively.

IP-rated enclosure vs non-IP-rated enclosure Infographic

productdif.com

productdif.com